- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HX80

-

Size:

-

12''*19''(300*483mm)

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HXCELL

-

Model Number:

-

HX80

-

Size:

-

12''*19''(300*483mm)

Dongying Huixin and Ruixin Materials Co., Ltd. is located in Hekou District, Dongying City, the Yellow River Delta Ecological Economic Zone. It is a professional core material processing and manufacturing enterprise in China. The company was established in 2018 with a registered capital of RMB 10000. Dongying Huixin and Ruixin Materials Co., Ltd. is mainly engaged in the research and development, production, and sales of sandwich pre cut molding materials, which are applied in wind turbine blades and serve the domestic and international wind power markets.

Dongying Huixin and Ruixin Materials Co., Ltd. adheres to the business philosophy of "quality establishment, honest operation, and technological development", establishes and improves a product quality assurance system, and organizes production strictly in accordance with international and industry standards and quality management systems. The company adheres to the policy of "honest operation, quality assurance, and continuous improvement" and takes a people-oriented, institutionalized and standardized management path. We are willing to establish honest cooperative relationships with friends from all walks of life, for mutual benefit and common development. We warmly welcome domestic and foreign customers to visit, guide, and negotiate business.

|

Process form

|

Process capacity

|

Scope of application

|

remarks

|

|

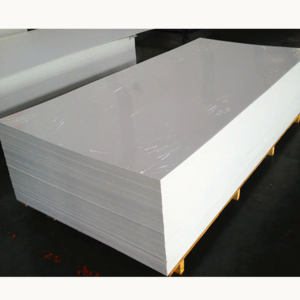

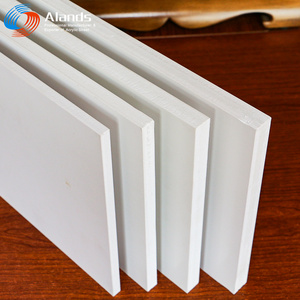

PVC flat(PB)

|

thickness:1~85mm

|

After the sheets are sliced, no extrasurface treatment. For the curved surface, it can be adapted by the thermoforming of the

plain sheets |

Thickness, width, type, etc. can be customized

|

|

Perforated foam core(DK)

|

thickness: 3~70mm

Hole diameter:2-3mm

Holespace:20*20,30*30,40*40 |

Have the around 2mm diameter hole inthe foam, the actual hole size can beadjusted based on the foam core thick-ness and the

density. With the hole, theair under the sheets can be expelledand the resin will be fluit to another side. |

|

|

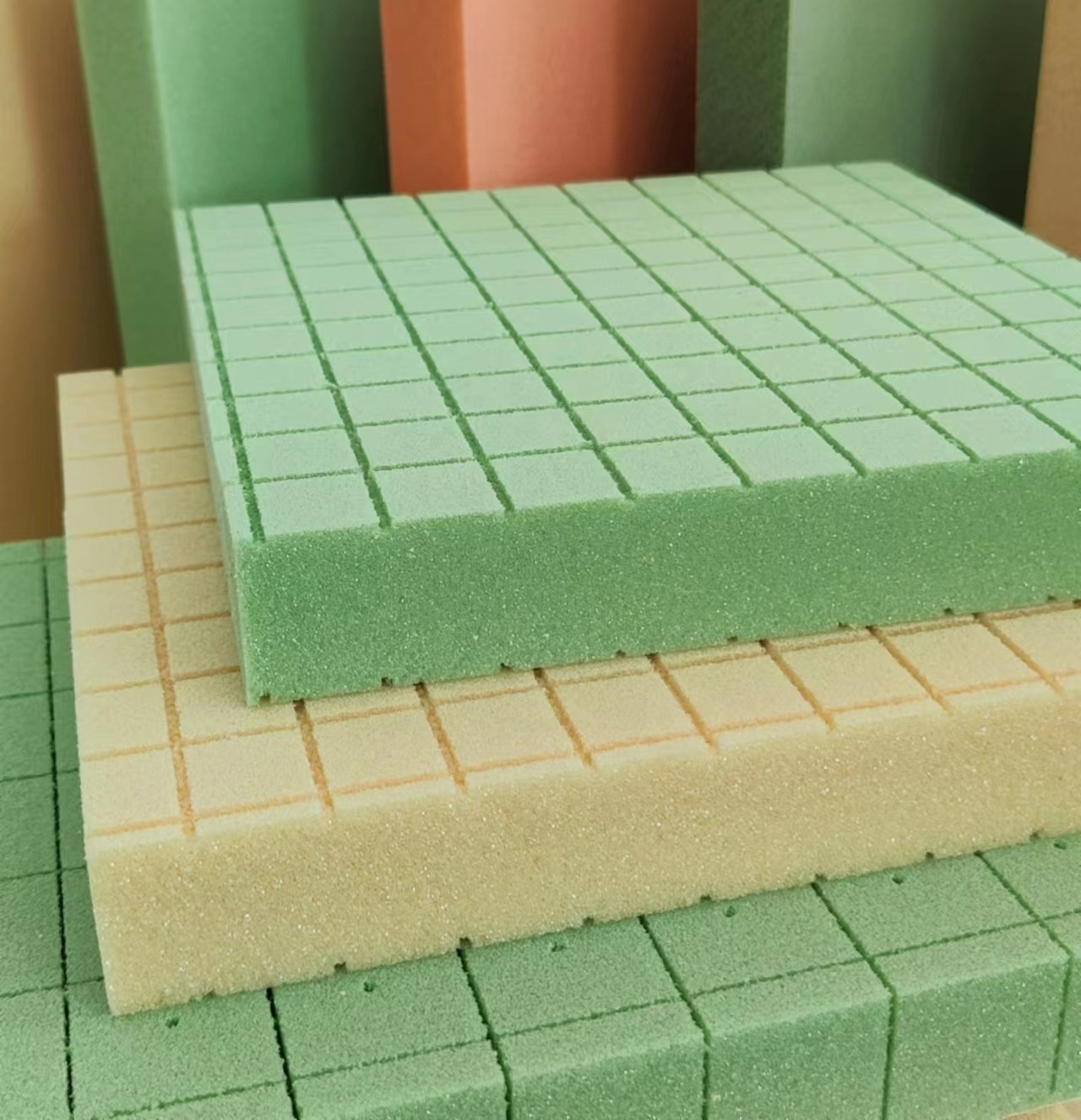

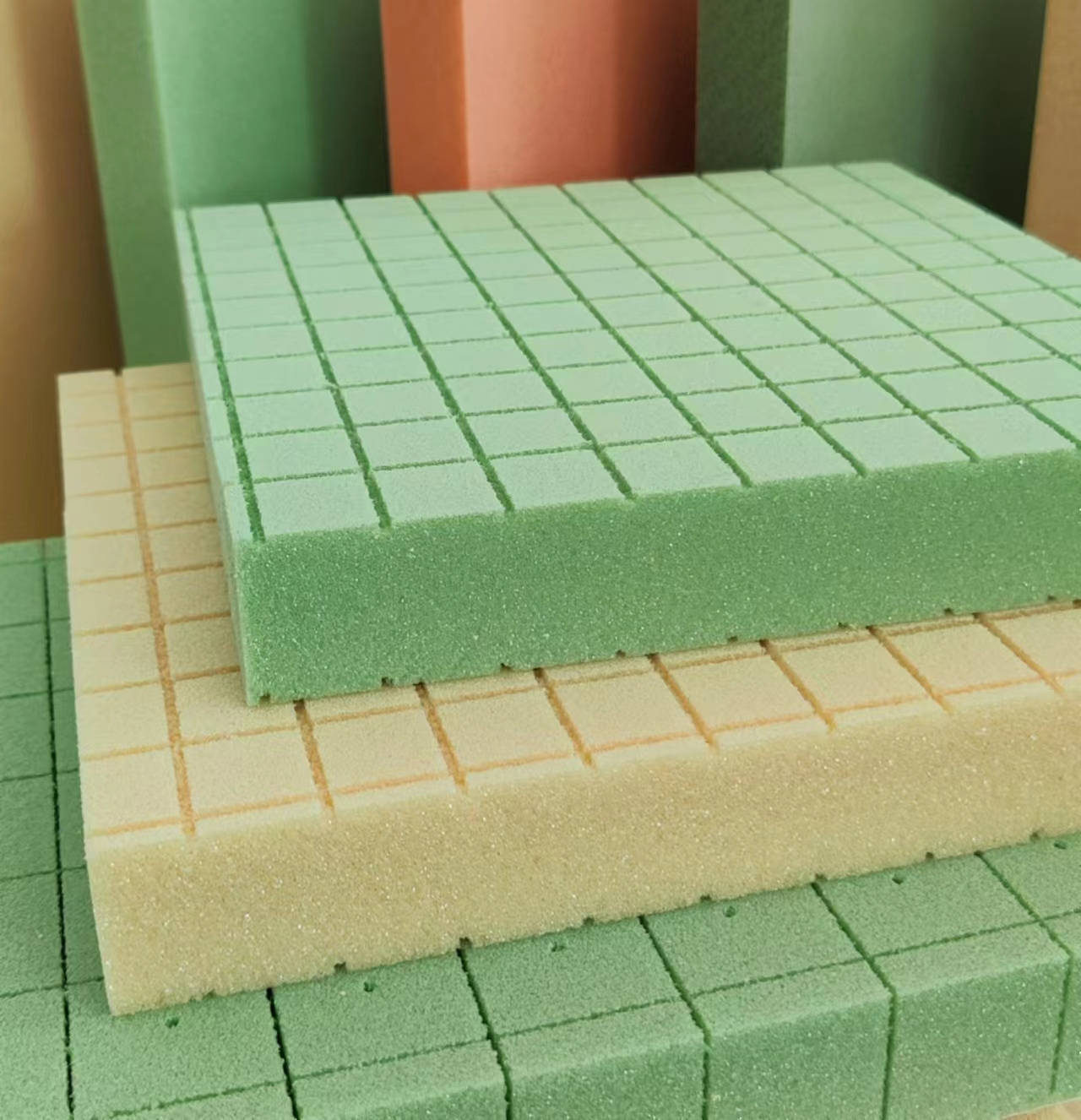

Profile foam core with light slot

(LKKC) |

thickness: 5~70mm.

Slot width: 2±0.5mm Slot depth: 2±0.5mm

space:20*20,30*30mm.

|

The sheet surface is grooved as theresin infusion channel. The groove canbe made on one side or both sides, inone direction or

both directions.With the resin infusion processingmethod, the groove will be used as theresin infusion channels, expell theair in the layup. |

|

|

Slotted form core perforated(CK)

|

thickness:5~70mm

Slot space:20*20,30*30mm.

Holespace:20*20,30*30

|

Based on the grooved surface finishingsheets, have the hole in the groove, thediameter is 2mm, the groove can be inthe length

direction or the width direc-tion, the groove distance is 20mm. |

|

|

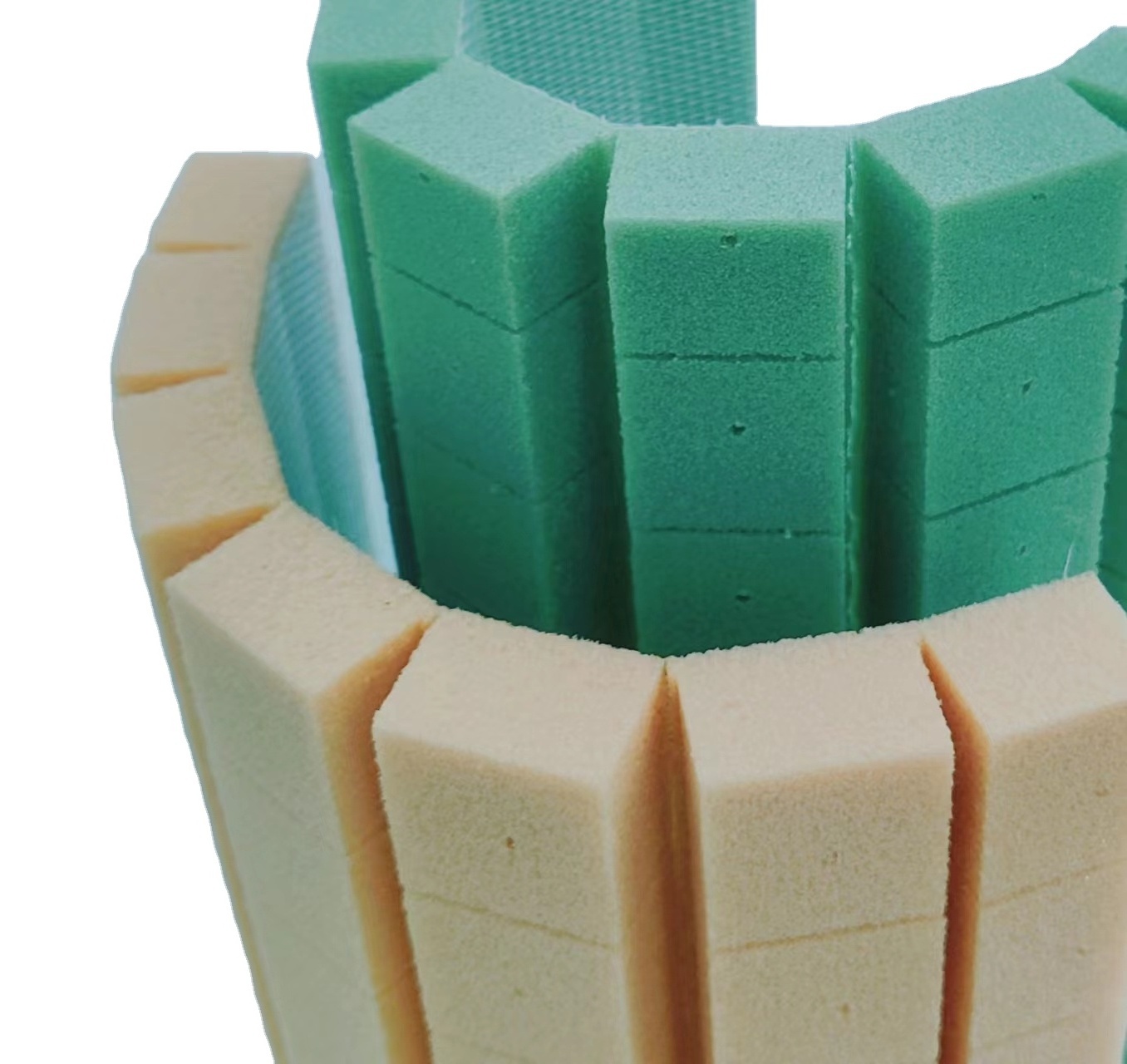

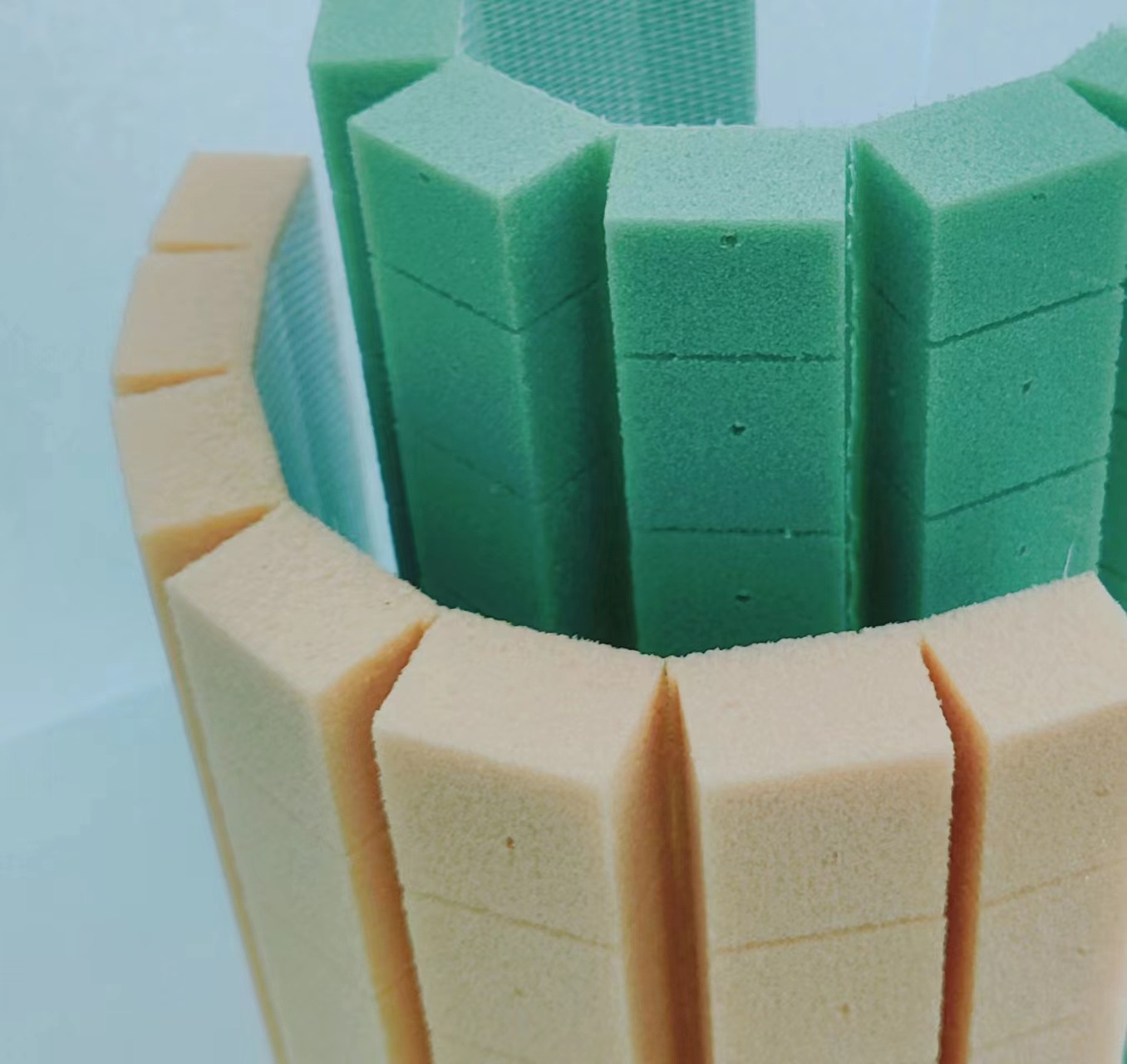

Profile slotted perforated foam core

(LKCK) |

thickness:5~50mm

Slot width:0.9-1mm

Slot space:30*30,40*40mm. |

The foam is cut into small particles inlength and width direction on one sideThe glass fiber scrim is bonded on theother side.It

is used on the curved sur.face |

|

|

Hyperbolic foam core(SQ)

|

Slot depth is 55-60% of foam core

Slot space:20*20mm, 30*30mm,40*40mm |

The sheets are cut to the 55-60%through the core thickness. The cutlocation of both sides is stagged.lt is used on the curved

surfaces. Compared with the countoured cut sheets.the resin absorption is lower. |

|

Hot Searches