- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

100 KG

-

Product Type:

-

Liquid Powder

-

Additional Capabilities:

-

Homogeneous

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Qiangzhong

-

Voltage:

-

110V-480V

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

2.2 kW

-

Key Selling Points:

-

Sanitary

-

Product name:

-

Water powder mixer

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 2900 r.p.m

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

100 KG

-

Product Type:

-

Liquid Powder

-

Additional Capabilities:

-

Homogeneous

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Qiangzhong

-

Voltage:

-

110V-480V

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

2.2 kW

-

Key Selling Points:

-

Sanitary

-

Product name:

-

Water powder mixer

Products Description

Features

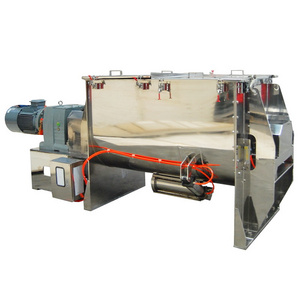

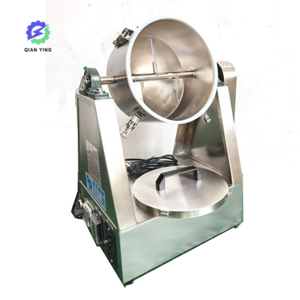

The mixture pump is also called water powder mixer, liquid material mixer, liquid material mixing pump, etc. It has the advantages of unique appearance, compact size, environmental protection and cleanliness, energy saving, high efficiency, rapid mixing and convenient transportation. The equipment is to fully mix the powdery material and liquid through a high speed rotating impeller to make it a required mixture and send it out. And it can absorb materials with a maximum temperature of 80 degrees. It can quickly mix the liquid material and can be used for the production of fruit juices and other beverages to achieve the desired benefits.

The pump is mainly composed of feeding hopper, butterfly valve, pump casing I, II, impeller, main shaft, mechanical seal, water cooling jacket, pump seat, belt transmission device, motor, etc. All parts of the equipment that are in contact with the materials are made of high-quality and corrosion-resistant stainless steel, which meets food health requirements. When the device is working, the motor drives the main shaft and the impeller through the belt, and the impeller rotates at a high speed in the pump casing II to achieve the purpose of mixing the liquid. The impeller is made of Ocr19N19, which is easy to take apart and wash, and it prevent bacteria from gathering. The mechanical seal is composed of a static ring, a dynamic seal ring, a stainless steel spring and a compression seal ring. There is also an external seal that prevents liquid leakage. The main shaft and the motor are driven by a V-belt, and the pump is equipped with a water cooling jacket and a tensioner. The motor and wiring part of this pump can effectively prevent the accumulation of water and damp, and it is in line with electricity safety. The motor and the pump base are connected by bolts, which makes the whole machine can bemoved arbitrarily without a fixed installation foundation.

For your Detailed description and drawings, please send us inquiry and request!

Working Principle

The pump consists of a main body and an impeller, which are mounted perpendicular to each other. It sucks liquids and solids separately through a double-walled pipe, preventing them from clumping before entering the main part. The liquid enters the main body of the pump at high speed and at the same time a vacuum is generated at the center of the rotor and the stator to suck solids. By adjusting the valve below the hopper, the solids can be evenly inhaled. The equipment is advanced design, multi-functional, high production efficiency and durable. It can quickly and uniformly mix a variety of solids without contact with the air, and the material is fully mixed and recycled. It can disperse and emulsify materials in the shortest time, narrowing the particle size distribution range, and finally obtaining a fine, long-term stable product.

Following control components are optional

● Pneumatic valve

● high-low level sensor

● Pneumatic or electric vibrators

The pump can be equipped with an exchange station for operating and protecting the machine.

The standard exchange station has the following basic functions:

Stop/start

emergency stop

Motor protection

Vibrator type

● Pneumatic Vibrator: This vibrator is made by rolling a roller on a steel tank. Its frequency can be changed by adjusting the air which enters the vibrator.

● Electric vibrators: The motor is centrally located on each side of the axis of rotation to provide the necessary vibration. The rotating shaft generates a centrifugal force that can be changed by changing the mass.

Typical Application 1:

Quickly dissolve a variety of powder products to produce a solution with a solids content of no more than 15%. It is commonly used in the rapid dissolution of milk powder, pectin, additives, sucrose and other materials.

Typical Application 2:

A centrifugal pump was added between the pump and the dosing tank to feed the pump. This system can process a solution with a relatively large solids content. The high-speed liquid produced by the centrifugal pump can accelerate the dissolution of the dry powder, and it is mostly used for the process of a solution having a solid content of 25% or less in the final solution.

Typical Application 3:

This system is equipped with two rotor pumps, cause the rotor pump has a greater advantage in conveying materials containing high viscosity, and has a relatively high pressure. This system is designed to handle mixed high solids content solutions, especially solutions with solids content above 50%.

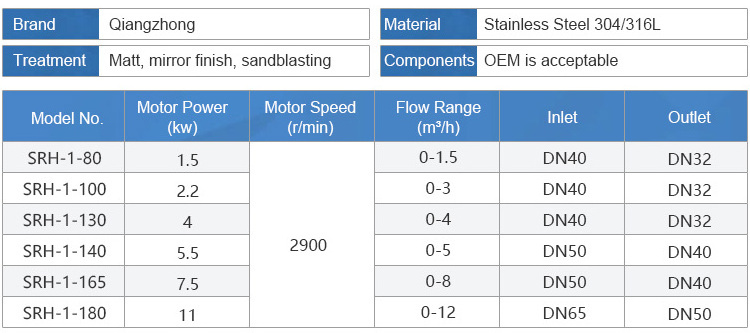

Product Paramenters

Send an inquiry to obtain Manuals and Videos for detailed operation instruction and Advice on optimize work process.

Common Structural Types According to the characteristics of the materials and the user's process requirements, we will choose the appropriate structural type and speed.

Advantages

|

Certification

|

25 National Patents, Audited by SGS/TUV/CE/ISO9001

|

|

Quality Guarantee

|

Complaint rate as low as 5‰ for 15 years. If you decide to purchase from us, any malfunction happened, once you enquiry us, we will reply you solution within 48 hours except the special reasons

|

|

Short Lead Time

|

Lead time is flexible. Short turnaround of replacement parts made by substantial storage, Normally we are 20% faster than others. If you have urgent orders, pls feel free to contact us. We will get the job done with 100% satisfaction.

|

|

24/7 Available

|

All your inquiry will be responded within 1 hour. All your quotation will be satisfied within 12 hours.

|

|

Why choose us?

|

•100% manufacturer

• Rich production experience •Strict Quality Control System •Flexible MOQ •Punctual delivery •Excellent and Experienced Team |

Hot Searches