- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YULONG

-

Model Number:

-

FRP rebar

-

Surface Treatment:

-

Fully Threaded

-

Dimensions:

-

Diameters from 4mm to 40mm

-

Item:

-

FRP rebar

-

Material:

-

FRP, GFRP, Fiberglass reinforced polymer

-

Production process:

-

Pultrusion, pultruded GFRP bars

-

Raw material::

-

polyester resin, epoxy resin, vinylester resin, glass fiber

-

Density::

-

1.5-2.0 g/cm3

-

Certification::

-

ISO9001,ISO140001

-

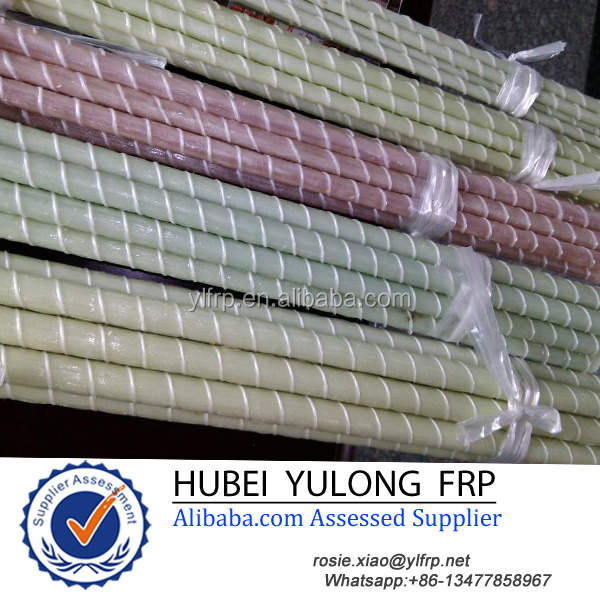

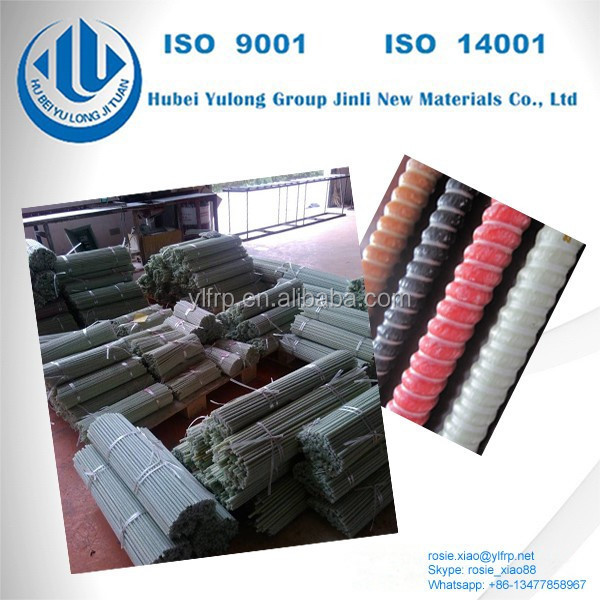

Color:

-

Grey, Blue, Yellow, Red, or customized

-

Packing:

-

in bundles, bulk, pallet

-

Sample:

-

Free sample, buyer pay for shipping fee

-

Lead time:

-

15-20 days for one container

Quick Details

-

Application:

-

Coal Mine, Civil Construction, concrete reinforcement

-

Technique:

-

Pultrusion

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YULONG

-

Model Number:

-

FRP rebar

-

Surface Treatment:

-

Fully Threaded

-

Dimensions:

-

Diameters from 4mm to 40mm

-

Item:

-

FRP rebar

-

Material:

-

FRP, GFRP, Fiberglass reinforced polymer

-

Production process:

-

Pultrusion, pultruded GFRP bars

-

Raw material::

-

polyester resin, epoxy resin, vinylester resin, glass fiber

-

Density::

-

1.5-2.0 g/cm3

-

Certification::

-

ISO9001,ISO140001

-

Color:

-

Grey, Blue, Yellow, Red, or customized

-

Packing:

-

in bundles, bulk, pallet

-

Sample:

-

Free sample, buyer pay for shipping fee

-

Lead time:

-

15-20 days for one container

Factory Price FRP Rebar for concrete reinforcement

Fiber glass rebar, FRP rebar, GFRP rebar, Composite rebar,reinforcing bar with diameter from 6mm to 38mm

manufactures composite Rebars by combining the pultrusion process and an in-line winding & coating process for the outside sand surface. The FRP composite rebar is made from high strength glass fibers along with an extremely durable vinyl ester resin. The glass fibers impart strength to the rod while the vinyl ester resin imparts excellent corrosion resistance properties in harsh chemical and alkaline environments. For improved stiffness and mechanical properties a carbon/vinyl ester product is available. FRP rebar significantly improves the longevity of civil engineering structures where corrosion is a major factor. As compared to con-ventional steel rebars, composite rebars should be a suitable alternative to steel reinforcing in:

·Architectural Concrete: cast stone, architectural cladding, balusters, column facades, window lentils, architectural precast elements, hand railing, and statuary and fountains, etc.

·Concrete exposed to de-icing salts in: bridge decks, railroad grade crossings, median barriers, parking garage elements, and salt storage facilities, etc.

Concrete exposed to marine salts in: seawalls, water breaks, buildings & structures near waterfront, aquaculture operations, and floating marine docks, etc.

·Applications Subjected to Other Corrosive Agents: Wastewater treatment plants; petrochemical plants; pulp/paper mills; liquid gas plants; pipelines / tanks for fossil fuel; cooling towers; chimneys; mining operations of various types; nuclear power and dump plants.

·Applications Requiring Low Electric Conductivity or Electromagnetic Neutrality: Aluminum and copper smelting plants; manholes for electrical and telephone communication equipment; bases for transmission / telecommunication towers; airport control towers; magnetic resonance imaging in hospitals; railroad crossing sites, and specialized military structures.

·Tunneling / Boring Applications Requiring Reinforcement of Temporary Concrete Structures: Structures including mining walls; underground rapid transit structures and underground vertical shafts.

·Weight Sensitive Structures: Concrete construction in areas of poor load bearing soil conditions, remote geographical locations, sensitive environmental areas, or active seismic sites posing special issues that the use of lightweight reinforcement will solve.

·Thermally Sensitive Applications: Apartment patio decks; thermally insulated concrete housing and basements; thermally heated floors and conditioning rooms.

Features:

Non-corrosive

Tensile strength is more than twice that of steel

Non-metallic and non-conductive

Consistent modulus of elasticity

Deformation patterns are the same as with steel

Four times lighter than steel

Pre-fabricated ACI standard angles and bends available

Coefficient of thermal expansion more similar to concrete than that of steel

Rock Bolts:

pultruded Rockbolt comes with a surface

roughened by helical winding or textured surface for enhanced shear bonding between the grout and the rod with high-pressure injection moulded thread and composite nut.

Advantages:

High strength and impact toughness

Non-Corrosive

Non-Conductive

Dimensionally-Stable-Under-Thermal-Loading

Outstanding anchorage capability.

Excellent performance in high deformation ribs.

Installed with standard techniques and equipment.

Easily handled and transported.

Fire resistant and anti-static rating.

Cutability without the danger of sparks.