- Product Details

- {{item.text}}

Quick Details

-

Plastic Type:

-

PP Woven Fabric + PE Coat, PP Woven Fabric + PE Coat

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

WANLIN

-

Model Number:

-

Woven PP Bag

-

Material Structure:

-

Polypropylene(PP)

-

Material:

-

100% vingin Polypropylene(PP)

-

Certificate:

-

ISO9001;ISO14001; Test Report;

-

MOQ:

-

320000pcs for 40HQ Container

-

Package:

-

6000-10000 per Pallet

-

Application:

-

Cement,Plaster,Mortar,Putty,Tile Adhesive

Quick Details

-

Industrial Use:

-

Chemical

-

Bag Type:

-

Bag With Valve

-

Feature:

-

Moisture Proof

-

Plastic Type:

-

PP Woven Fabric + PE Coat, PP Woven Fabric + PE Coat

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

WANLIN

-

Model Number:

-

Woven PP Bag

-

Material Structure:

-

Polypropylene(PP)

-

Material:

-

100% vingin Polypropylene(PP)

-

Certificate:

-

ISO9001;ISO14001; Test Report;

-

MOQ:

-

320000pcs for 40HQ Container

-

Package:

-

6000-10000 per Pallet

-

Application:

-

Cement,Plaster,Mortar,Putty,Tile Adhesive

|

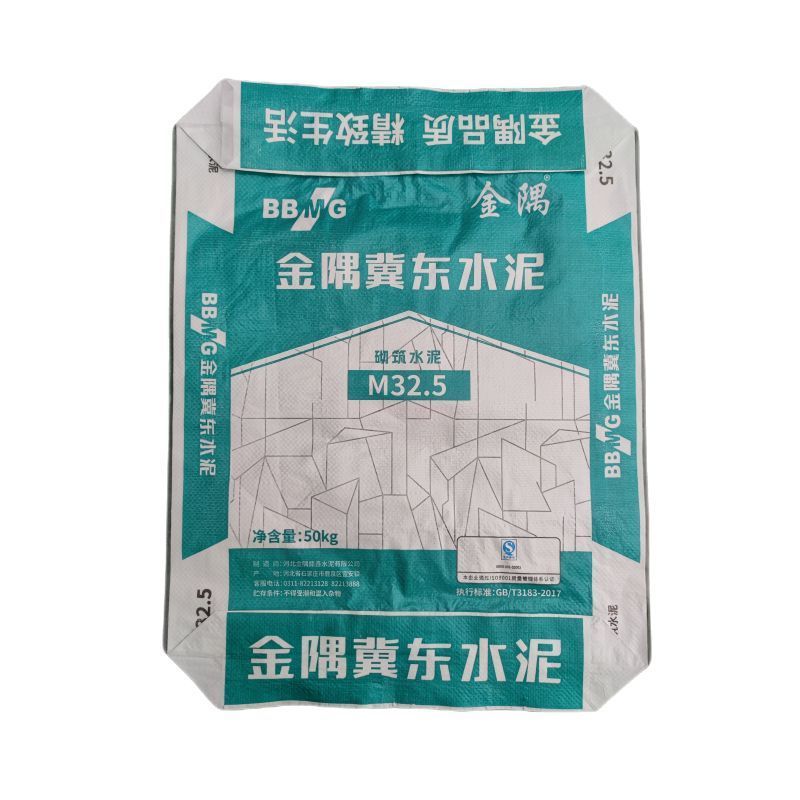

Product |

90GSM (65gsm+25gsm) PP Cement Bag Plastic 50KG |

|

Material |

PP woven fabric Laminated with PE film |

|

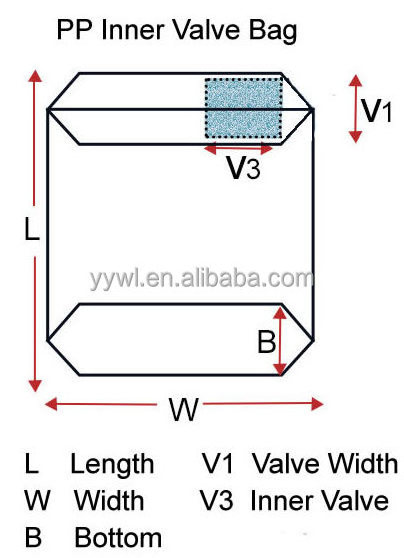

Dimension(cm) |

Length of the Sack 61cm; |

|

|

Width of the Sack 50cm ; |

|

|

Width of Top - Bottom Cover Patch 10cm ; |

|

|

Depth of the Valve 16cm ; as per customer’s requirements |

|

Weight of per Sack |

80±3 grams ; as per customer’s requirements |

|

Color |

White ; Beige; Kraft Brown; |

|

Printing |

Max 4 colors in each side ; Flexographic-Printing |

|

Uncoat Fabric |

65 grams/m 2 |

|

Laminating Coat |

25grams/m 2 |

|

Average Break Strength of Coating(According Standard ISO-13934-1) |

(a) Warp Direction≥65kgf (b) Weft Direction ≥55kgf (c) Top Seam ≥55kgf (d) Bottom Seam ≥55kgf |

|

Elongation At Break |

(a) Widthwise 10-15% (b) Lengthwise 16-24% |

|

Perforation |

80-125 Nm 3 /h @50Mbar or As per customer’s requirements |

|

Warrenty |

12 Month |

|

Application |

Cement , Mortar , Plaster , Bricks , Concrete , Putty powder, Gypsum, Carbon powder and other construction material, etc |

|

Packaging |

4000-10000pcs/pallet |

|

Production Capability |

60000000 bags/Month |

|

Delivery Time |

The first container within 30 days after order confirmation , the later as per customer’s requirements |

|

Payment Terms |

T/T 50% in advance, T/T the balance before delivery |

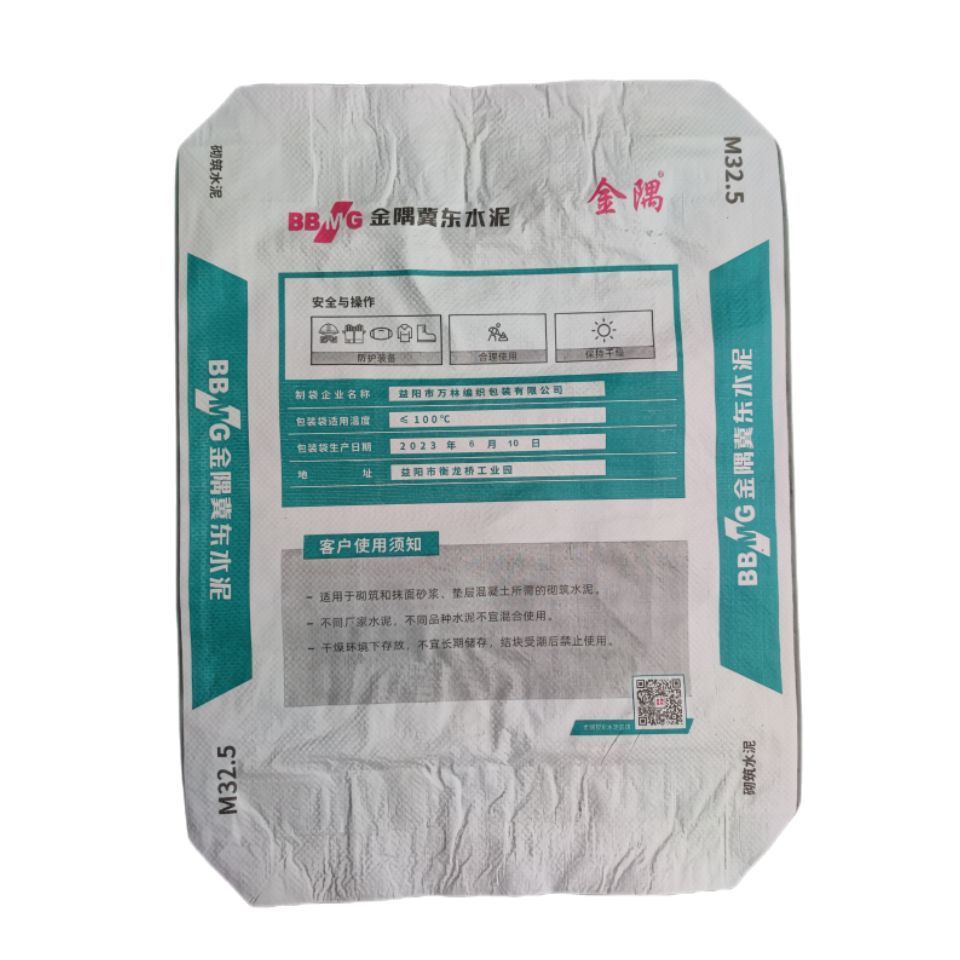

The block bottom with valve – Ad*Star bag is characterized mainly by its high resistance to breaks, falls and friction. It is a strong and waterproof bag used for packaging different products from different industries.

It consists of a block bottom facilitating the palletization. This valve bag has an automatic closure, which allows it to escape at all seams. The laminated bag or block-bottomed BOPP bag offers an astonishing visual through the impression of each of its sides.

This range of bags can be declined to infinity according to the dimensions, the resistance or the choice of printing. The manufacturing process is very rigorous and requires frequent quality checks. Available in many standard formats, it can also be produced according to precise specifications according to the specific needs of our customers.

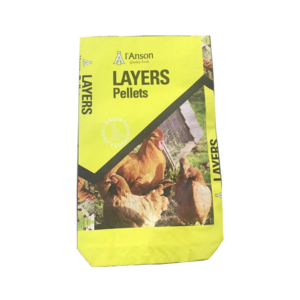

Example of use: cement bag, plaster bag, calcium carbonate (CaCO3) bag, various raw materials, etc.

Promote your brand by personalizing your bag.

Contact our specialists for advice or a personalized quote.

Resistance

BOPP woven polypropylene bags or laminated bags offer high resistance to breakages and drops. They also offer better moisture resistance than kraft paper bags. In addition, we offer an anti-UV treatment for bags exposed or stored in the sun.

Printability

Two printing possibilities are offered to customers. Direct printing on the laminated bag or by adding a layer of BOPP printed inside, to protect your visuals, while offering excellent print quality.

The main feature of this product is that it is possible to have an impression on each of its sides.

Dimensional stability

A wide and varied range with different well mastered widths, our processes are adapted to produce the desired widths.