- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

according to the model

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

6000X2000X2500

-

OEM/ODM:

-

ACCEPT

-

Application:

-

Milk Making Plant

-

Raw material:

-

Fresh Liquid Milk

-

Capacity:

-

500-10000L

-

Keywords:

-

Milk Production Line Plant

-

Feature:

-

High Efficiency Low Cost

-

Suit for:

-

Milk Making

-

Advantage:

-

High Quaility

-

Color:

-

Customized Color

-

Control type:

-

Automatic Control

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

bayern

-

Voltage:

-

220V/380V

-

Power:

-

according to the model

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

6000X2000X2500

-

OEM/ODM:

-

ACCEPT

-

Application:

-

Milk Making Plant

-

Raw material:

-

Fresh Liquid Milk

-

Capacity:

-

500-10000L

-

Keywords:

-

Milk Production Line Plant

-

Feature:

-

High Efficiency Low Cost

-

Suit for:

-

Milk Making

-

Advantage:

-

High Quaility

-

Color:

-

Customized Color

-

Control type:

-

Automatic Control

Product Description

Pasteurized milk: milk processed by pasteurization is characterized by low temperature sterilization at 72-85 ℃. It can kill harmful bacteria in milk and preserve nutrients and pure taste.

UHT milk: The milk processed by UHT production line can be stored for a long time without deterioration, and the milk quality is stable without refrigeration. It can be used with aseptic filling machine.

Production line introduction:

After centrifugation, standardization, homogenization, sterilization and cooling, the milk can be directly filled after pasteurization and homogenization without any additives. Due to low temperature sterilization, the beneficial bacteria in milk can be retained, and the nutritional value is particularly high. Moreover, the cost of the equipment is low and the package is simple.

Pasteurized milk is a kind of "low temperature pasteurized milk". The harmful microorganisms in raw milk have been generally killed, but some other microorganisms will be retained. Therefore, this kind of milk is required to be refrigerated at about 4 ℃ in transportation, sales, storage and other links, so as to prevent the microorganisms in it from "active".

glass bottles, etc.

|

Model

|

Power

|

Stirring motor power

|

Weight

|

Tank size

|

|

300L

|

9kw*2

|

0.37kw

|

120kg

|

850*750mm

|

|

500L

|

12kw*2

|

0.37kw

|

220kg

|

1000*850mm

|

|

800L

|

15kw*2

|

0.75kw

|

320kg

|

1100*850mm

|

|

1000L

|

12kw*4

|

0.75kw

|

380kg

|

1200*900mm

|

Product Details

Product Display

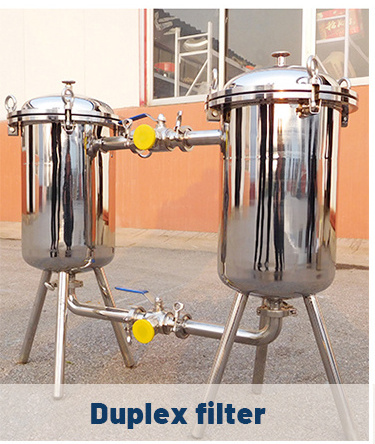

Duplex filter

The duplex filter is composed of two stainless steel filters in parallel, which are mainly used to filter the cattle hair and impurities mixed in the milking process. The two filters can work independently without affecting the production.

Preheating tank

The function of the milk preheating tank is to heat the raw milk to about 60 ° C and serve the homogenization of the next process, because the homogenization effect of milk at about 60 ° C is good.

Homogenizer

The homogenizer is used to crush and refine the macromolecular fat protein globules in the milk under the action of extrusion and strong impact, and evenly disperse them in the milk to make the milk smooth and taste good. Make the yogurt fermented well in the later stage.

Sterilization tank

Milk processed by pasteurization is characterized by sterilization at 72-85 ℃, which can sterilize harmful bacteria in milk and preserve nutrients and taste.

Fermentation tank

The appropriate temperature for yoghurt fermentation is about 43 ° C. After fermentation, the fatty acid in the milk is twice as much as that in the raw milk, and the nutrition is easier to be absorbed by the human body.

Refrigeration tank

The precooling tank can greatly improve the production line capacity, cool the sterilized milk, not affect the sterilization work of the sterilization tank, and save power and water consumption.

CIP cleaning system

CIP automatic cleaning can save labor and is mainly applicable to medium and large production lines. The C | P cleaning system is composed of three tanks: acid water tank, alkali water tank and clean water tank. Clean the equipment by circulating three kinds of liquids respectively.

Our strengths:

*It can be designed according to the special requirements of users

*Multiple products can be produced on the same production line

*It can produce high quality products and keep nutrients

*Aromatic substances can be added and mixed precisely

*Extend the shelf life of products *Large output and small loss

*Application of high technology to save energy consumption

*According to the customer's choice, we can provide a variety of milk configuration.

*Multiple products can be produced on the same production line

*It can produce high quality products and keep nutrients

*Aromatic substances can be added and mixed precisely

*Extend the shelf life of products *Large output and small loss

*Application of high technology to save energy consumption

*According to the customer's choice, we can provide a variety of milk configuration.

Applicable Scope

Hot Searches