- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Voltage:

-

220V 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Easternpack

-

Dimension(L*W*H):

-

1800*1800*3000mm

-

Product name:

-

Doypack Packing Machine

-

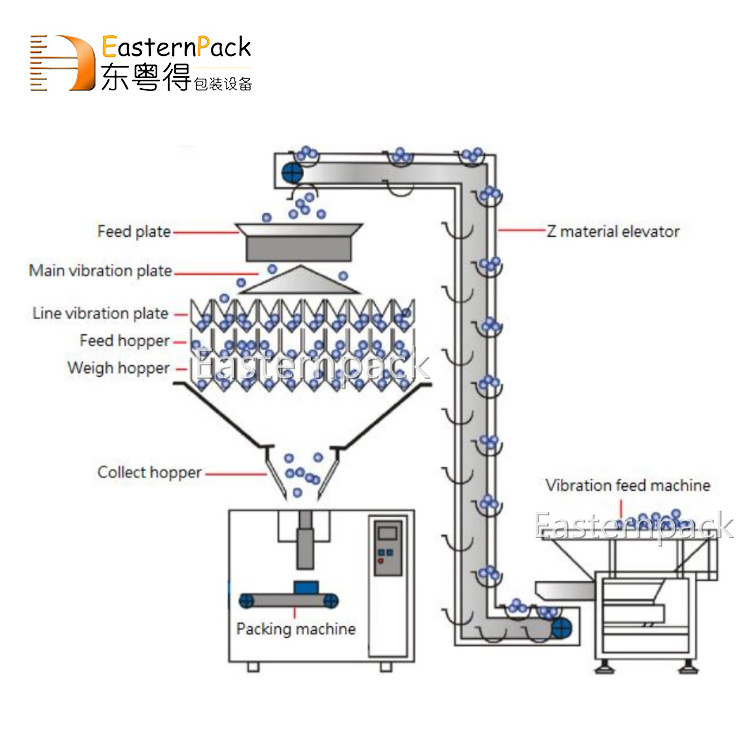

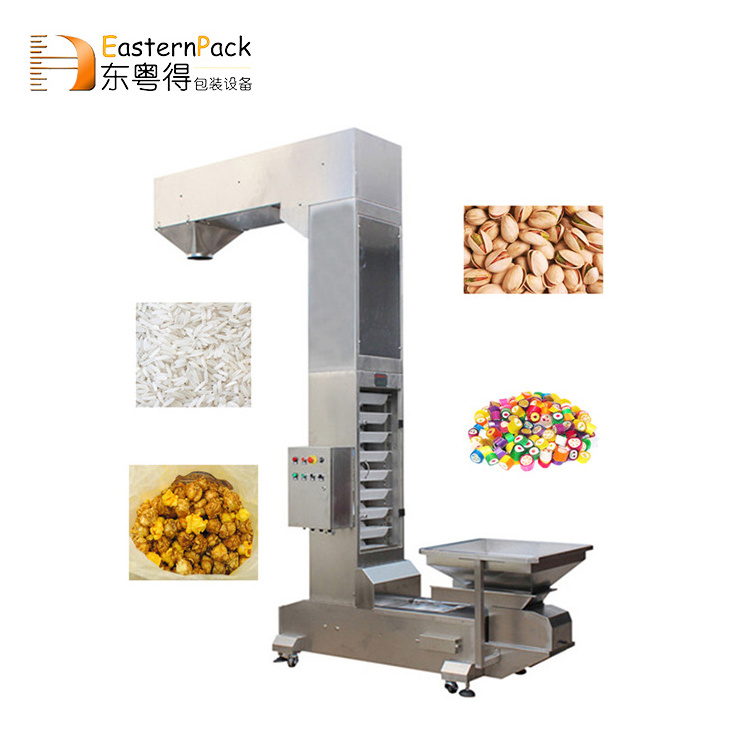

Feeding System:

-

According to packing material

-

Machine Surface:

-

304-Stainless steel

-

Gross Weight:

-

500KG

-

Packing Speed:

-

30-60bag/min

-

Station:

-

8 working stations

-

Packing Bag Size:

-

L: 100-350mm W : 60-200mm

-

Accuracy:

-

±1g (≤100g) / ± 1%( >100g) according to material

-

Usage:

-

Bag Making

-

Main Function:

-

Weighing Forming Packing Sealing

Quick Details

-

Function:

-

FILLING, Labeling, Sealing, Convey,weigh,fill product,seal bag,output finished bags

-

Packaging Type:

-

Bags, Stand-up Pouch, gusseted pillow bag, 3 sides sealing bag, 4 side seal bag, Cartons, CANS, Bottles, Barrel, Film, Foil, Belt, Pouch, case

-

Packaging Material:

-

Paper, Plastic, OPP/CPP. OPP/CE. MST/PE/PET/PE, Metal, Glass, Wood

-

Weight (KG):

-

500

-

Voltage:

-

220V 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Easternpack

-

Dimension(L*W*H):

-

1800*1800*3000mm

-

Product name:

-

Doypack Packing Machine

-

Feeding System:

-

According to packing material

-

Machine Surface:

-

304-Stainless steel

-

Gross Weight:

-

500KG

-

Packing Speed:

-

30-60bag/min

-

Station:

-

8 working stations

-

Packing Bag Size:

-

L: 100-350mm W : 60-200mm

-

Accuracy:

-

±1g (≤100g) / ± 1%( >100g) according to material

-

Usage:

-

Bag Making

-

Main Function:

-

Weighing Forming Packing Sealing

|

Technical Parameters

|

|

|

|

|

||||

|

Model

|

D-150D

|

D-180D

|

D-200D

|

D-250D

|

||||

|

Bag width

|

100-150mm

|

100-180mm

|

140-200mm

|

170-250mm

|

||||

|

Bag length

|

120-220mm

|

120-250mm

|

150-350mm

|

150-400mm

|

||||

|

Measuring range

|

Max.800ml

|

Max.1200ml

|

Max.1200ml

|

Max.2000ml

|

||||

|

Packing speed

|

30-60bag/min

|

|

|

|

||||

|

Power supply

|

220V 50/60Hz

|

|

|

|

||||

|

Machine size

|

1200*900*1300mm

|

1800*1100*900mm

|

1800*1200*1500mm

|

2100*1200*1500mm

|

||||

Machine Feature:

1. The packaging process is fully automatic and requires no manual operation.

1. The packaging process is fully automatic and requires no manual operation.

2. The contact parts of the materials are all made of SUS316L stainless steel, in line with GMP standards.

3. Different filling devices can be selected according to the character of the filling materials.

3. Different filling devices can be selected according to the character of the filling materials.

4. Intelligent detection for bag filling and sealing.

5. Germany Siemens PLC system, France Schneider Electric System. Stable performance and durability.

6. Japan OMRON intelligent temperature control system, automatic sealing temperature compensation, temperature control accuracy. The seal is beautiful and generous.

7. The pneumatic originals of the whole machine are all selected from Taiwan Yadeke brand, with long working life and convenient maintenance and replacement.

5. Germany Siemens PLC system, France Schneider Electric System. Stable performance and durability.

6. Japan OMRON intelligent temperature control system, automatic sealing temperature compensation, temperature control accuracy. The seal is beautiful and generous.

7. The pneumatic originals of the whole machine are all selected from Taiwan Yadeke brand, with long working life and convenient maintenance and replacement.

8. The filling part can be washed directly, and the power supply part should be avoided.

FAQ

Q: Are you a factory or trading company?

A: We are a factory and manufacturer.

Q: How does your factory do regarding quality control?

A: We pay much attention on quality controlling and strictly follow the Professional standard forms from getting order, parts procession,assembly for whole set of machine and debug to the shipment.

Q: Where is your factory located? How can I visit there?

A: Our factory located at Guangdong province ,China.You can fly to Guangzhou Baiyun air port.We will arrange to pick you up from the airport ;it is Around 30 mins from the airport to our factory by car.Or you can take fast Train to Guangzhou from other countries in China.We will pick you up from the station.

Q: What’s the service and guarantee can you offer?

A: One year guarantee for main parts of machine like PLC,touch screen,ect;Machine installation and worker training service;Free technical support for lifelong;Material support.

A: We are a factory and manufacturer.

Q: How does your factory do regarding quality control?

A: We pay much attention on quality controlling and strictly follow the Professional standard forms from getting order, parts procession,assembly for whole set of machine and debug to the shipment.

Q: Where is your factory located? How can I visit there?

A: Our factory located at Guangdong province ,China.You can fly to Guangzhou Baiyun air port.We will arrange to pick you up from the airport ;it is Around 30 mins from the airport to our factory by car.Or you can take fast Train to Guangzhou from other countries in China.We will pick you up from the station.

Q: What’s the service and guarantee can you offer?

A: One year guarantee for main parts of machine like PLC,touch screen,ect;Machine installation and worker training service;Free technical support for lifelong;Material support.

After Sales Service

A. The warranty would be one year. The damaged one (not include the part which is made damaged by man) can be changed by the

supplier, but the demand-side needs to burden the transportation fee.

B. The above quotation is not including the maintenance fee which would happen at home or abroad.If the demand-side asks for

maintenance door-to-door, then need to pay all the fees which will be charged.

C. The supplier will provide the spare parts of the machine and support for technology for the good.

supplier, but the demand-side needs to burden the transportation fee.

B. The above quotation is not including the maintenance fee which would happen at home or abroad.If the demand-side asks for

maintenance door-to-door, then need to pay all the fees which will be charged.

C. The supplier will provide the spare parts of the machine and support for technology for the good.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches