- Product Details

- {{item.text}}

Quick Details

-

Quality:

-

reliable

-

Suit for:

-

copper stranding

-

Automatic Grade:

-

semi-automatic

-

Color:

-

as clients request

Quick Details

-

Use:

-

Twisting

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UT

-

Quality:

-

reliable

-

Suit for:

-

copper stranding

-

Automatic Grade:

-

semi-automatic

-

Color:

-

as clients request

Gongyi UT Machinery

WhatsApp/Viber/ Phone: 0086-18236968979

Skype: orion.chai

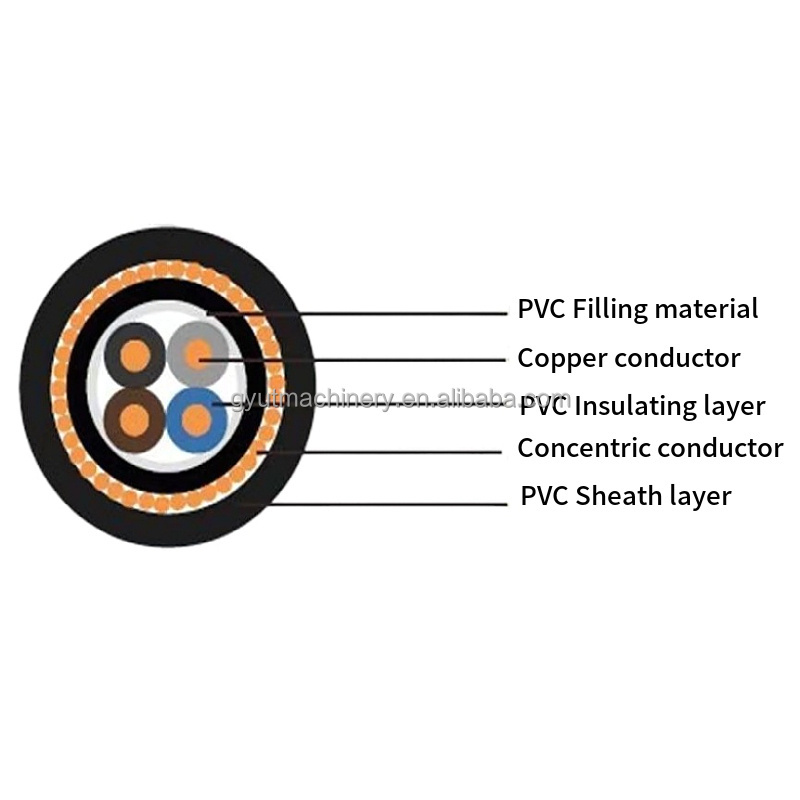

Good performance wire twisting machine, 3 4 wire cable stranding machine

the Concentric cable making machine include 8 parts:

1.the 1.4 Meter pay off stand

2.the 32core stranding machine

3.the 36core stranding machine

4.the wrapping machine

5.the caterpillar 800kg

6.the 2meter shaftless take-up machine

7.the control cabinet+converter

8. the transmission system

Concentric cable machinery advantages:

1. High standard quality, key eletric components are original international brand.

2. UT Machinery strong company power to ensure you can find us for support at any time.

3. We do not only produce fiber cable production line machine, but also produce fiber cable to helps ourself to insist on improving our machine in time.

4. We have rich experience 10 years machine and cable manufacture, enough training technicians.

5. We have a large professional teams for pre-sales and after sales services.

6. After sales service for free spare parts, online support, field installation, commissioning and training, field maintenance and repair service, v i d e o technical support.

7. Advanced technology applied to our machine with the times.

8. Support with cable raw material information and cable production technology.

9. ISO9001, ISO14001, OHSAS18001 certified, CE certified support.

10. Techical Datasheets, Machine Inventment Evaluation, OEM support.

We trust you will know how to evaluate and build your wire cable production factory by refering to our professional guides, but also know clearly the advantages of produce fiber cables by yourself.

Shipping and packing:

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Pre-sale:

1. Suggest to client suitable raw material, final product capacity ;

2. Introduce machine's structure and features in detail, explain the price component;

3. answer client concerned questions.

After-sale:

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to client, for your better learn about the machine's condition.

3. Delivery machine in time, taking photos during loading, so you can "remote monitoring" your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site for installation instruction.