- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

12 Months

-

Configuration:

-

Teach pendant+controller+servo driver and 3 servo motors

-

Communication manner:

-

Internal bus

-

Working voltage:

-

24V

-

Main board network interface:

-

RS485 communication interface

-

Expansion axis:

-

One CANopen servo axis can be expanded

-

Rated power:

-

S1:750W S2:750W S3:400W

-

Maximum power:

-

Supports maximum power output of 1000W for a single axis

-

Regenerative braking:

-

External regenerative braking resistor

-

Usage environment:

-

Temperature:-20℃-60℃ Humidity:5%-80%

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lavichip

-

Model Number:

-

DS1M-3-355001-000

-

Warranty:

-

12 Months

-

Configuration:

-

Teach pendant+controller+servo driver and 3 servo motors

-

Communication manner:

-

Internal bus

-

Working voltage:

-

24V

-

Main board network interface:

-

RS485 communication interface

-

Expansion axis:

-

One CANopen servo axis can be expanded

-

Rated power:

-

S1:750W S2:750W S3:400W

-

Maximum power:

-

Supports maximum power output of 1000W for a single axis

-

Regenerative braking:

-

External regenerative braking resistor

-

Usage environment:

-

Temperature:-20℃-60℃ Humidity:5%-80%

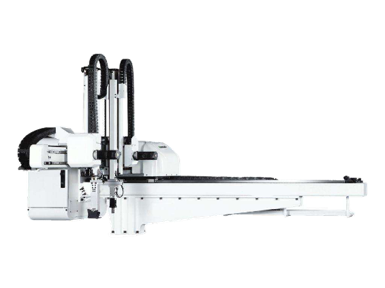

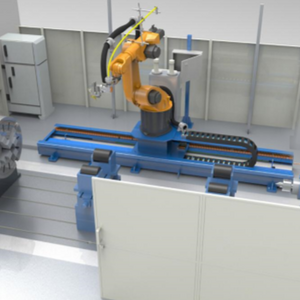

Poster

Lavichip's injection molding products have experienced ten years of iterative updates from 2013 to now, and have become a very mature industrial line. From button control systems to touchable pulses, CANopen bus technology, RTEX, and EtherCAT high-end bus technology. In the research and development upgrade from split system to highly integrated drive and control system, Lavichip's injection molding control system have been h

ot products in the injection molding industry.

Using higher standards in software and hardware to meet customer needs and solve customer' problems. And now, Lavichip has become a professional solution supplier in the field of motion control.

Product's details

Product's parameter

|

Name

|

3 axis integrated drive and controller system for IMM

|

|

|

|

Model

|

DS1M-3-553001-000

|

|

|

|

Teach pendant

|

HT0806BIM

|

HT0804BIM

|

|

|

IO board

|

1

|

7

|

|

|

Axis

|

3

|

3

|

|

|

Teach pendant with IoT

|

Not support

|

Support

|

|

|

Enable buttons

|

Support

|

Support

|

|

|

Keyboard

|

Function keys: 20 keys, lifespan 100,000 times

|

Function keys: 21 keys, lifespan 100,000 times

|

|

|

Working voltage

|

DC24V

|

|

|

|

Display screen

|

8-inch FTF color screen, resolution 800*600

|

|

|

|

Input

|

29 channels of universal input + 7 channels of origin input(Optocoupler isolation, active low level, input current 5mA)

|

|

|

|

|

|

|

|

|

Output

|

16 transistor outputs (NPN type, optocoupler isolation, active low level, output current 500mA) + 5 relay outputs (normally open

single contact, 220V/5A)

|

|

|

|

Control manner

|

Internal bus

|

|

|

|

Communication rate

|

1Mbps

|

|

|

|

Languages

|

English, Chinese

|

|

|

|

Update manner

|

Updated by USB

|

|

|

|

Main board network interface

|

RS485 communication interface

|

|

|

|

Expansion axis

|

One CANopen servo axis can be expanded

|

|

|

|

Communication with servo

|

Internal Bus

|

|

|

|

Languages

|

Support 8 languages

|

|

|

|

Update manner

|

Update by USB

|

|

|

|

Main board network interface

|

RS485 communication interface

|

|

|

|

Rated power

|

S1:750W S2:750W S3:400W

|

|

|

|

Maximum power

|

Supports maximum power output of 1000W for a single axis

|

|

|

|

Regenerative braking

|

External regenerative braking resistor

|

|

|

|

Usage environment

|

Temperature:-20℃—60℃ Humidity:5%—80%

|

|

|

|

Monitor function

|

Can monitor speed, current position, bus voltage, load rate, temperature, encoder multi-turn data, etc.

|

|

|

|

Protective function

|

Overspeed, overcurrent, overvoltage, overload, abnormal braking, abnormal encoder position, position out of tolerance, etc.

|

|

|

Hot Searches