Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 years

-

Brand Name:

-

ZRFX

-

Model Number:

-

XBD11.2/20G-TRL

-

Place of Origin:

-

China

-

Horsepower:

-

61.22 HP

-

Outlet Size:

-

100mm

-

Power:

-

45KW, 45kw

-

Product name:

-

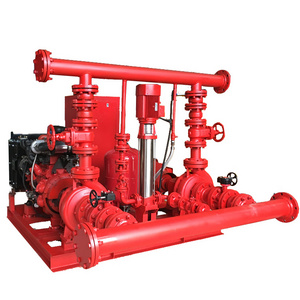

single stage fire pump

-

Color:

-

Red

-

Speed:

-

2900r/min

-

Frequency:

-

50 Hz

-

Motor:

-

100% Copper Wire

-

MOQ:

-

1 Set

-

Material:

-

Cast Iron

-

Usage:

-

fire fighting

-

Brand:

-

ZRFX

Quick Details

-

Application:

-

Other, Commercial Buildings, District Energy, Drinking water treatment, Family Homes, HVAC OEM, Industrial Utilities, Irrigation and Agriculture, Mining industry

-

Pressure:

-

Other

-

Voltage:

-

380v

-

Warranty:

-

1 years

-

Brand Name:

-

ZRFX

-

Model Number:

-

XBD11.2/20G-TRL

-

Place of Origin:

-

China

-

Horsepower:

-

61.22 HP

-

Outlet Size:

-

100mm

-

Power:

-

45KW, 45kw

-

Product name:

-

single stage fire pump

-

Color:

-

Red

-

Speed:

-

2900r/min

-

Frequency:

-

50 Hz

-

Motor:

-

100% Copper Wire

-

MOQ:

-

1 Set

-

Material:

-

Cast Iron

-

Usage:

-

fire fighting

-

Brand:

-

ZRFX

1、 Overview of fire pump products:

XBD (vertical fire pump) is developed on the basis of the original pipeline of XBD multi-stage fire pump. It is used to transport water without solid particles and liquid with physical and chemical properties similar to water. It is suitable for all kinds of occasions such as residence, hotel, office building, commercial building, factory, hospital and so on.

The performance and technical conditions of xbd-gdl series fire pumps produced by our company meet the requirements of national standards. The products have passed the test of national fire equipment quality supervision and testing center.

2、 Features of fire pump products:

1. The hydraulic model has high efficiency and wide performance range.

2. Vertical structure, small floor area.

3. Small vibration, low noise, the use of hydraulic balance axial force, so that the pump runs smoothly.

4. The inlet and outlet of fire pump are on the same horizontal axis with the same diameter and specification, which is convenient for pipeline connection and loading and unloading.

3.

The meaning of fire pump model

|

Fault phenomenon

|

Possible causes

|

Exclusion method

|

|

|

1. The inlet and outlet valves are not opened, the inlet and outlet pipelines are blocked, and the runner impeller is blocked

2.The running direction of the motor is wrong, and the motor speed is very slow due to lack of phase

3. Air leakage of suction pipe

4. The pump is not filled with liquid and there is air in the pump chamber

4. The inlet water supply is insufficient, the suction head is too high, and the

bottom valve leaks

5. The pipeline resistance is too large and the pump selection is improper

6. The pipeline resistance is too large and the pump selection is improper

|

2. Adjust the motor direction and tighten the motor wire

3. Tighten all sealing surfaces to remove air

4. Open the upper cover of the pump or open the exhaust valve to exhaust the air

5. Shutdown inspection and adjustment

(this phenomenon is easy to occur in grid connected water pipe and use with suction head)

6. Reduce pipeline bends

|

|

|

1. Check by reason 1

2. The pipeline and impeller of pump passage are blocked, and the valve opening is not enough

3. The voltage is low

4. Impeller wear

|

1. Press 1 to exclude

2. Remove the blockage and readjust the valve opening

3. Voltage stabilization

4. Replace impeller

|

|

Too much power,

|

1. Use in excess of rated flow

2. The suction head is too high

3. The pump bearing is worn

|

1. Adjust the flow and turn down the outlet valve

2. Decrease

3. Replace the bearing

|

|

|

1. Stabilize the pipeline 2. Increase suction pressure and exhaust 3. Reduce the vacuum 4. Replace the bearing 5. Adjust according

to 51. The pipeline support is not stable

2. Liquid mixed with gas

3. Cavitation

4. Bearing wear

5. Overload operation of motor

|

2. Increase suction pressure and exhaust

3. Reduce the vacuum

4. Replace the bearing

5. Adjust according to 5

|

|

|

1. Excessive flow and overload operation

2. Local friction

3. The motor bearing is damaged

4. Insufficient voltage

|

1. Turn down the outlet valve

2. Check and eliminate

3. Replace the bearing

4. Voltage stabilization

|

|

|

1. Mechanical seal wear

2. There are sand holes or cracks in the pump body

3. The sealing surface is not smooth

4. The mounting bolt is loose

|

1. Replacement

2. Welding repair or replacement

3. Trimming

4. Fastening

|

Hot Searches