- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

Vary model or as required

-

Weight:

-

KG

-

Motor:

-

Vertical Vibrating Motor

-

material of construction:

-

SUS 304 or 316, Q235A

-

frequency:

-

50 or 60 HZ

-

phase:

-

three or single

-

Noise level:

-

less than 75dB

-

Customized design:

-

accepted

-

Mesh range:

-

0.025---5mm

-

Product name:

-

vibrating sifter machine

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

S49-B

-

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

Vary model or as required

-

Weight:

-

KG

-

Motor:

-

Vertical Vibrating Motor

-

material of construction:

-

SUS 304 or 316, Q235A

-

frequency:

-

50 or 60 HZ

-

phase:

-

three or single

-

Noise level:

-

less than 75dB

-

Customized design:

-

accepted

-

Mesh range:

-

0.025---5mm

-

Product name:

-

vibrating sifter machine

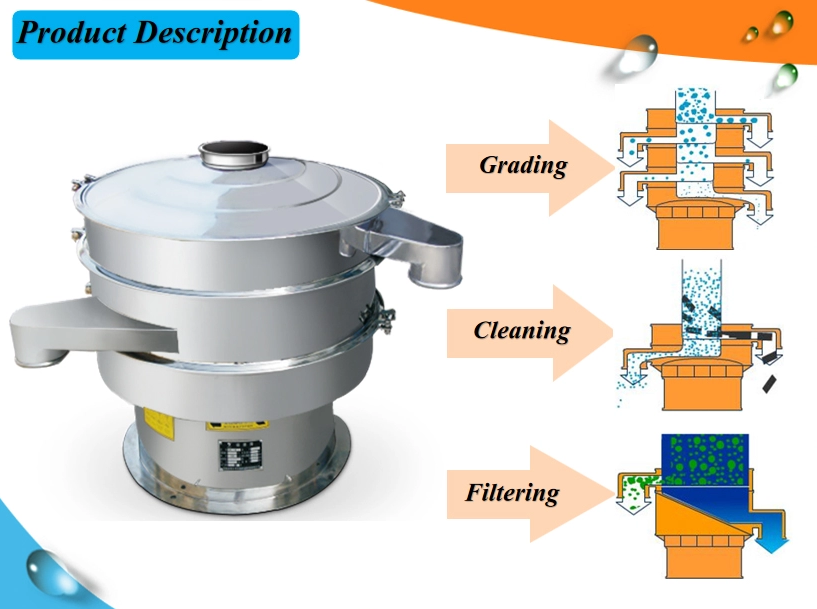

Product Description

Vibrating sifter belongs to a high precision fine powder separation machine. High screen efficiency and novel design are the main features of vibrating sifter.

①It adds the special cleaning device- bouncing ball.

②It can bounce up and down while the screen cloth is shaking, which can effectively avoid clogging.

③The sealing structure design and all- closed type which can be avoid polluting the environment .

④The installation is very safe and convenient .

Working principle of vibrating sifter

Detailed Images

The application of vibrating sifter

1.Chemical Industry: colophony, dope, industry leechdom, cosmetic, paint

2.Food Industry: sugar, amylum, rice powder, milk powder, soyabean milk, angel cake.

3.Paper-Making Industry: dope,white soil slurry, black and white liquid, disposed liquid.

4.Metallurgy Industry: aluminum powder, ceruse, copper powder, ore alloy powder.

Size Information

|

Size Code

|

Diameter (mm)

|

Mesh Area per deck (m2)

|

Number of decks

|

Power

(KW)

|

Maximum size to process(mm)

|

|

S494-B

|

430

|

0.13

|

1-5

|

0.25

|

20

|

|

S496-B

|

610

|

0.16

|

1-5

|

0.5

|

20

|

|

S498-B

|

760

|

0.44

|

1-5

|

0.75

|

30

|

|

S4910-B

|

910

|

0.63

|

1-5

|

0.8

|

30

|

|

S4912-B

|

1120

|

1.03

|

1-5

|

1.5

|

30

|

|

S4915-B

|

1460

|

1.65

|

1-5

|

2.2

|

50

|

|

S4918-B

|

1728

|

2.4

|

1-5

|

2.5

|

50

|

|

S4920-B

|

1910

|

2.98

|

1-5

|

2.5

|

60

|

Packing&Shipping

Company Introduction

Xinxiang Dongzhen Machinery Co., Ltd found in 1987 which has a professional team, is a manufacturer of vibrating sifters,tiny electromagnetic feeders, linear vibrating screens, centrifugal sifters, tumbler screens,gyratory screens and aluminum foil tape with well quipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in mining,food, chemical,metal powder and other industries.

FAQ

Q: What information do we need to help you choose a perfect machine?

1. Name and feature of the raw material

2.Aim of using: get rid of impurity, filtration, grading

3.granularity distribution

4.Handling capacity: kg /h, L/h

5.The raw material size: (mesh or mm)

6.The moisture of the material

7.The material of construction (stainless steel SUS 304 or 316, carbon steel Q 235 A)

8.How many layers you need?

9.The voltage , frenquency, phase (single or three)

1. Name and feature of the raw material

2.Aim of using: get rid of impurity, filtration, grading

3.granularity distribution

4.Handling capacity: kg /h, L/h

5.The raw material size: (mesh or mm)

6.The moisture of the material

7.The material of construction (stainless steel SUS 304 or 316, carbon steel Q 235 A)

8.How many layers you need?

9.The voltage , frenquency, phase (single or three)

Hot Searches