- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Anytester

-

Dimension(L*W*H):

-

1300mm*800mm*1750mm

-

Weight:

-

500 KG

-

Power:

-

1500, AC220V 50Hz, single-phase, 1500W

-

Fiber type:

-

Wool

-

Control mode:

-

Touch screen & PLC

-

Number of needle gilling box:

-

1

-

Draw ratio of gilling box:

-

2-5

-

Draw ratio of color sliver:

-

1-8

-

Fiber length:

-

80-120mm

-

Output speed:

-

6--30m/min

-

Can size:

-

250*550mm

-

warranty:

-

1 year

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Application:

-

lab

-

Production Capacity:

-

500set/year

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Anytester

-

Dimension(L*W*H):

-

1300mm*800mm*1750mm

-

Weight:

-

500 KG

-

Power:

-

1500, AC220V 50Hz, single-phase, 1500W

-

Fiber type:

-

Wool

-

Control mode:

-

Touch screen & PLC

-

Number of needle gilling box:

-

1

-

Draw ratio of gilling box:

-

2-5

-

Draw ratio of color sliver:

-

1-8

-

Fiber length:

-

80-120mm

-

Output speed:

-

6--30m/min

-

Can size:

-

250*550mm

-

warranty:

-

1 year

Product Description

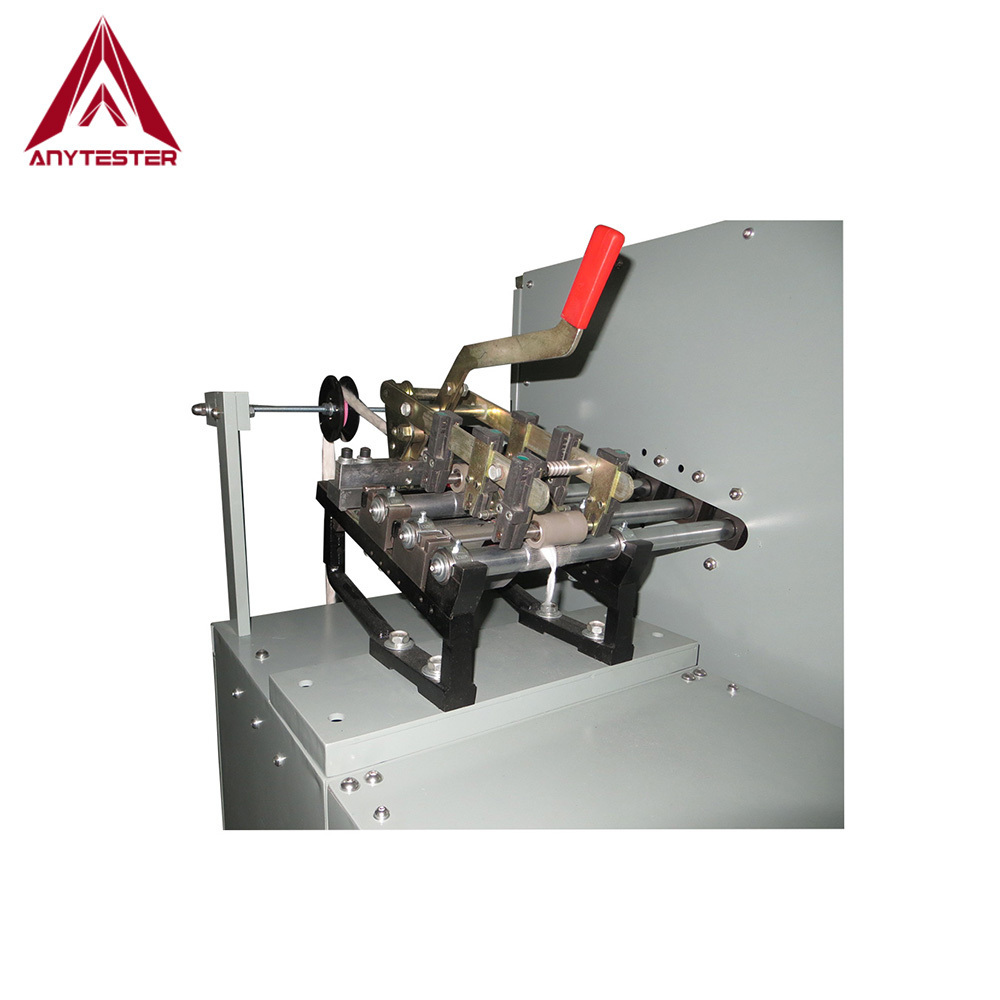

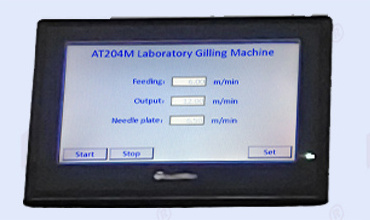

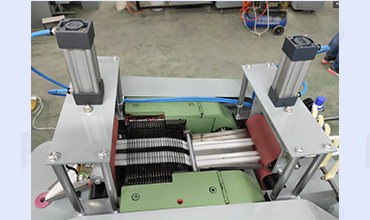

AT204M Laboratory Gilling Machine

is one of the most important equipment of long fiber processing system (such as worsted spinning system). In the long fiber spinning system, as the roller carding machine output sliver fiber straight parallelness and evenness does not meet the requirements of spinning, and some fiber still exist "Hook", can’t be directly spinning. Especially in the worsted spinning system, if directly use such sliver on combing machine, easy to cause fiber damage, comb needle damage and the production rate reduce. In order to improve the combing process, the gilling machine is frequently used in the former spinning process. Generally, 2 to 3 gilling box are used before the combing, so that the fiber can be parallel to the straight. After combing, 2-4 gilling box are used, it’s for improve the uniformity of the sliver. The main task of the needle comb process (gilling machine) is to improve the uniformity of the middle and long fiber in the sliver by the combination of multiple roots and drafts. Moreover, it is used to furtherly improve the parallelness and the degree of separation of the fibers by needle comb and to eliminate the hooks and curl in the same time. It repeated merging and drawing, so that fiber mixing evenly, and stabilize the yarn quality; to remove some small impurities and short hair.

Specification

|

Model

|

AT204M

|

|

Fiber type

|

Wool

|

|

Control mode

|

Touch screen & PLC

|

|

Number of needle gilling box

|

1

|

|

Draw ratio of gilling box

|

2-5

|

|

Draw ratio of color sliver

|

1-8

|

|

Fiber length

|

80-120mm

|

|

Motor power for feeding roll

|

90W

|

|

Motor power for needle plate

|

750W

|

|

Motor power for output roll

|

90W

|

|

Motor power for coiling device

|

90W

|

|

Output speed

|

6~30m/min

|

|

Can size

|

Φ250×550mm

|

|

Power

|

AC220V 50Hz, single-phase, 1500W

|

|

Dimension

|

1300mm×800mm×1750mm (L×W×H)

|

|

Weight

|

500Kg

|

Details & Features

★ Touch screen display and PLC control.

★ Doubling up to 8 slivers.

★ Pneumatic feeding roll and output roll.

★ One needle gilling box.

★ Special coiling device, hard to be blocked.

★ High-efficiency invertors and motors independently control feeding roll, needle plate box, output roll and coiling device.

★

Mini-type machine, save researching cost and easy to operate and maintain.

Mini-type machine, save researching cost and easy to operate and maintain.

Our Company

Onsite service

Installation and training service is available

Testing service

Free sample testing before order is available

Lead time

15 working days lead time for most product

Packing & Delivery

|

Packaging

|

|

|

|

Packaging Details

|

1. The equipment is covered with film is protect it from water vapour during the trip.

2. The box is filled with foam to protect the equipment from impact.

3. Exported wooden box made from plywood, don't need fumigated.

|

|

Payment

|

Payment Term

|

T/T

|

EXW

|

30% T/T in advance, paid the balance before shipment

|

||

|

|

|

FOB

|

|

||

|

|

|

CFR(C&F)

|

|

||

|

|

|

CIF

|

|

||

|

|

L/C

|

L/C amount above 50,000 usd, we can accept L/C at sight

|

|

||

|

|

West Union

|

Amount lower than 5000usd

|

|

||

|

|

West Union

|

|

|

||

|

Delivery Time

|

7~10days after receiving payment for one container

|

|

|

||

Contacting Us

Hot Searches