- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tengtai

-

Model Number:

-

TT123

-

Surface Treatment:

-

Smooth

-

Colors:

-

Customsize

-

Shape:

-

Customized Shape

-

Type:

-

FRP Composite Sheet

-

Bending strength:

-

≥190Pa

-

Tensile strength:

-

≥160MPa

-

Material:

-

Fiberglass Reinforced Polymer ( GFRP)

-

Product name:

-

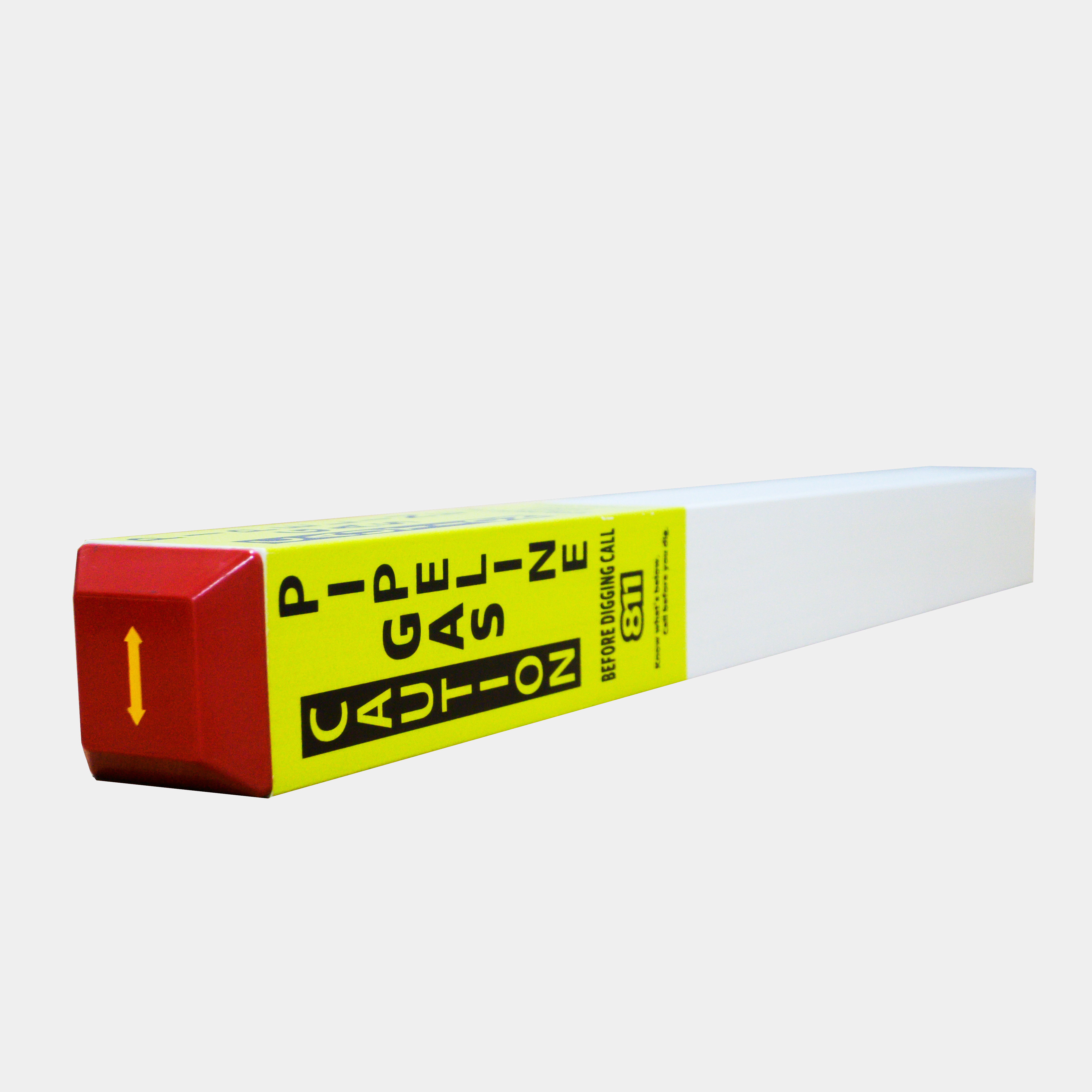

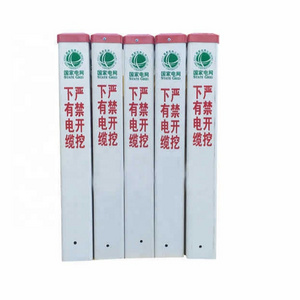

FRP warning sign

-

Thickness:

-

6-10mm

-

Keywords:

-

Fiber Glass Pipe

-

Feature:

-

Corrosion Resistance

Quick Details

-

Application:

-

chemical plant, construction

-

Technique:

-

Pultrusion

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Tengtai

-

Model Number:

-

TT123

-

Surface Treatment:

-

Smooth

-

Colors:

-

Customsize

-

Shape:

-

Customized Shape

-

Type:

-

FRP Composite Sheet

-

Bending strength:

-

≥190Pa

-

Tensile strength:

-

≥160MPa

-

Material:

-

Fiberglass Reinforced Polymer ( GFRP)

-

Product name:

-

FRP warning sign

-

Thickness:

-

6-10mm

-

Keywords:

-

Fiber Glass Pipe

-

Feature:

-

Corrosion Resistance

Product Description

|

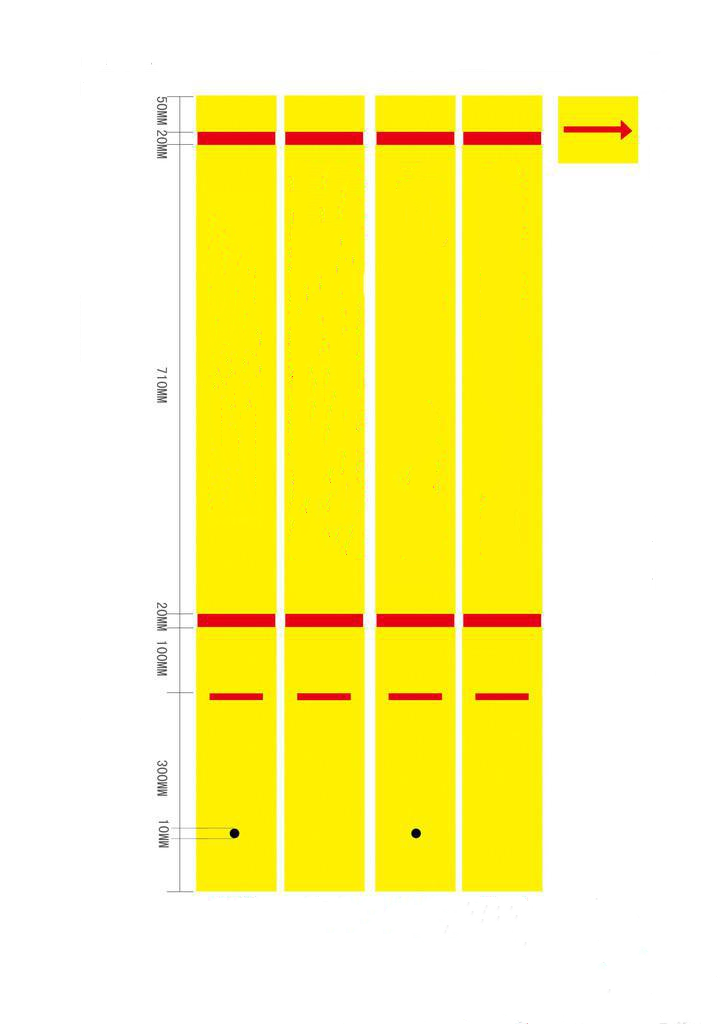

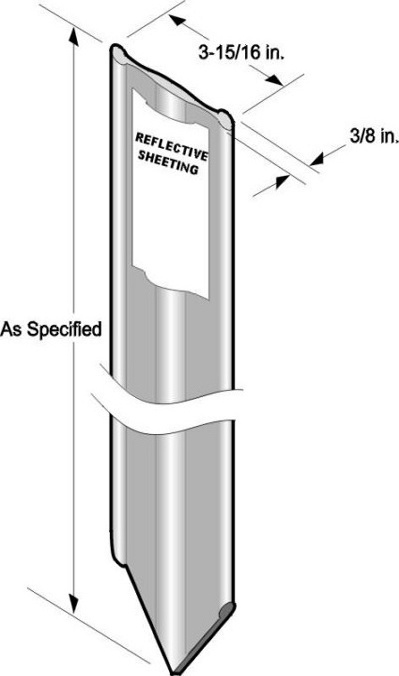

Item

|

FRP marker post

|

|

Dimension

|

Length: 62" / 66" / 72" / 78" are standard.

Custom lengths are available. |

|

Raw Materials

|

Reinforcement material: Fiberglass, glass mat, continuous strand mat, surfacing mat, needled mat.

Basis material: Unsaturated polyester resin |

|

Color

|

Yellow, Red, Blue, Green, other customized colors

|

|

Density

|

1.5-2.0 g/cm3

|

|

Packaging Details

|

Plywood pallet or customized packing way in extra cost.

|

|

Delivery Time

|

About 25 days after deposit received

|

|

Payment Terms

|

TT,L/C, Western Union, Money Gram..

|

|

Supply Ability

|

10000 pieces/month

|

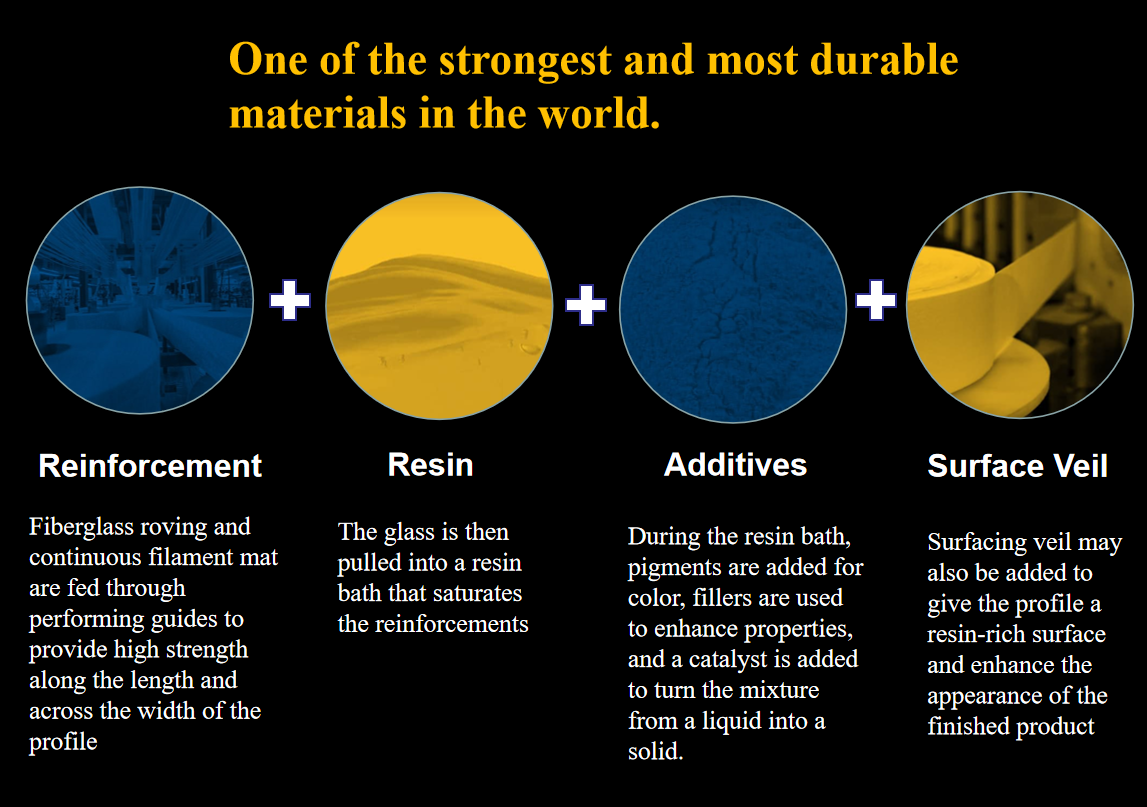

Raw Material(FRP)

FRP is also known as “composites,” and is a combination of: REINFORCEMENTS such as fiberglass roving and mat; RESIN such as polyester or vinylester; ADDITIVES such as pigments, UV inhibitors, fire retardant, etc.; and SURFACE VEIL which enhances corrosion resistance, UV protection and appearance.

FRP vs.Traditional Materials

TO WOOD, STEEL AND ALUMINUM

Fiberglass reinforced polymer (FRP) is one of the strongest, most durable building materials available today. It’s non conductive, dimensionally stable and extremely low maintenance. It offers the strength of steel at a fraction of the weight for efficient transportation and installation. And unlike traditional materials like wood, steel and aluminum, FRP won’t rust, corrode, warp, rot, decay or attract insect damage — so it’s ideal for harsh environments. In short, it’s a different way to solve your design challenges — one that can reduce costs and improve long-term performance.

Fiberglass reinforced polymer (FRP) is one of the strongest, most durable building materials available today. It’s non conductive, dimensionally stable and extremely low maintenance. It offers the strength of steel at a fraction of the weight for efficient transportation and installation. And unlike traditional materials like wood, steel and aluminum, FRP won’t rust, corrode, warp, rot, decay or attract insect damage — so it’s ideal for harsh environments. In short, it’s a different way to solve your design challenges — one that can reduce costs and improve long-term performance.

|

|

FRP Composites Pultruded GFRP

|

Steel

A 709 Grade 50

|

Aluminum

6061-T651

|

Wood

Douglas Fir

|

|

CORROSION, ROT AND INSECT RESISTANCE

|

Resists a broad range of chemicals and is unaffected by moisture or immersion in water. Resists insect damage.

|

Subject to oxidation and corrosion. Requires painting or galvanizing for many applications.

|

Can cause galvanic corrosion. (Anodizing and other coatings increase corrosion resistance.)

|

Can warp, rot and decay when exposed to moisture, water and chemicals. Susceptible to attack by insects such as termites and

marine borers. |

|

STRENGTH

|

Has greater flexural strength than timber and pound-for-pound is often stronger than steel and aluminum in the lengthwise

direction. |

Homogeneous material.

|

Homogeneous material.

|

Modulus of rupture is 12,000 psi

|

|

WEIGHT

|

Weighs 75% less than steel and 30% less than aluminum.

|

Could require lifting equipment to move and place.

|

Lightweight — about a third of the weight of copper or steel.

|

Specific gravity 0.48

|

|

ELECTRICAL CONDUCTIVITY

|

Nonconductive. High dielectric capability.

|

Conducts electricity. Grounding potential.

|

Conducts electricity. Grounding potential.

|

Can be conductive when wet.

|

|

STIFFNESS

|

Up to 3.3 times as rigid as timber. Will not permanently deform under working load.

|

Modulus of elasticity: 29 x 10^6 psi

|

Modulus of elasticity: 10 x 10^6 psi

|

Modulus of elasticity: up to 1.6-1.8 x 10^6 psi*

|

|

IMPACT RESISTANCE

|

Will not permanently deform under impact. Glass mat in pultruded parts distributes impact load to prevent surface damage, even in

subzero temperatures. |

Can permanently deform under impact.

|

Easily deforms under impact.

|

Can permanently deform or break under impact.

|

|

ENVIRONMENTAL IMPACT

|

Not hazardous to the environment.

|

Not hazardous.

|

Not hazardous.

|

May be treated with hazardous preservatives or coatings to increase corrosion/rot/insect resistance. Contributes to depletion of

forest systems. |

|

COST

|

Lower installation costs, less maintenance and longer product life allow for a lower lifecycle cost.

|

Lower initial material cost.

|

Part price comparable to FRP.

|

Has a lower initial cost, but usually requires more maintenance and replacement.

|

|

FABRICATION

|

Can be field-fabricated using simple carpenter’s tools with carbon or diamond tip blades — no torches or welding required. Light

weight allows easier transport and installation. |

Often requires welding and cutting torches. Heavier material requires special equipment to erect and install.

|

Good machinability (welding, brazing, soldering or mechanical joining).

|

Can be field-fabricated using simple carpenter’s tools.

|

|

Property

|

FRP

|

Steel

|

Aluminum

|

Wood

|

|

Density (lb/ft3 )

|

107-120

|

490

|

169

|

30

|

|

Tensile Strength (psi)

|

30,000 (LW)

|

65,000

|

45,000

|

/

|

|

Tensile Modulus (x 10^6 psi)

|

2.8 (LW)

|

30

|

10

|

/

|

|

Flexural Strength (psi)

|

30,000 (LW)

|

65,000

|

45,000

|

12,000

|

|

Flexural Modulus (x 10^6 psi)

|

1.8 (LW)

|

30

|

10

|

1.6 - 1.8

|

|

Thermal Conductivity (BTU in. /(hr ft2 °F))

|

4

|

323

|

1,160

|

0.8

|

|

Thermal Expansion (x 10-6 in./in./°F)

|

7 to 8

|

6 to 8

|

13

|

1.7 to 2.5

|

Product Advantages

Manufacturing Technique

Pultrusion

It is the manufacturing process that creates continuous lengths of FRP.

Pultruded composite profiles have seen an increase in demand in recent years and for good reason. With the high durability and non-corrosive character traits of fiberglass reinforced polymers, it

is a clear advantage to the customer to select a pultruded profile.

The manufacturing process described above is also convenient,

efficient and low-cost in comparison to other options on

the market. The continuous process of pultrusion makes

manufacturing cost-efficient and eco-friendly. Pultrusion also

garners consistent high quality composites, reducing error in

production and in turn offering a greater customer satisfaction.

Reinforcement

The process typically starts by pulling in two forms of fiberglass reinforcement. Creels of fiberglass roving provide unidirectional strength along the length of the profile, and rolls of woven fiberglass mat provide multidirectional reinforcement.

Wet-Out

The fiberglass reinforcements are pulled through a bath of thermoset resin — typically polyester or vinylester — as well as pigments to add color, filler to enhance properties, and a catalyst to aid in curing. Resin also provides an additional form of reinforcement.

Surface Veil

Surface veil can be added to enhance the surface appearance and provide corrosion resistance and UV protection of the final product.

Curing

Wet-out reinforcements are pulled through the heated pultrusion die, which begins the thermosetting process that causes the resin to “cure” or harden. By the time the part exits the die, a solid, rigid profile in the exact shape of the die cavity has been formed with all the reinforcements laminated inside.

Cutting

The finished product is then pulled to the cut-off saw and cut to the desired length. After cutting, it is placed in stock at one of our warehouses.

SALES AND SERVICE NETWORK

Application

Hot Searches