- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

400V

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

12*1.2*2.7m

-

Usage:

-

Thermal and power application

-

Power(W):

-

10kW-200kW

-

Production Rate:

-

30-600 Nm3/hr per hour

-

Type of gas cleanning:

-

Gas Purification System

-

Type of Gasifier:

-

Downdraft Fixed Bed Gasifier

-

Efficiency:

-

75% High Efficiency

-

Material:

-

Carbon steel

-

Certification:

-

CE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAITAI POWER

-

Voltage:

-

400V

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

12*1.2*2.7m

-

Usage:

-

Thermal and power application

-

Power(W):

-

10kW-200kW

-

Production Rate:

-

30-600 Nm3/hr per hour

-

Type of gas cleanning:

-

Gas Purification System

-

Type of Gasifier:

-

Downdraft Fixed Bed Gasifier

-

Efficiency:

-

75% High Efficiency

-

Material:

-

Carbon steel

-

Certification:

-

CE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

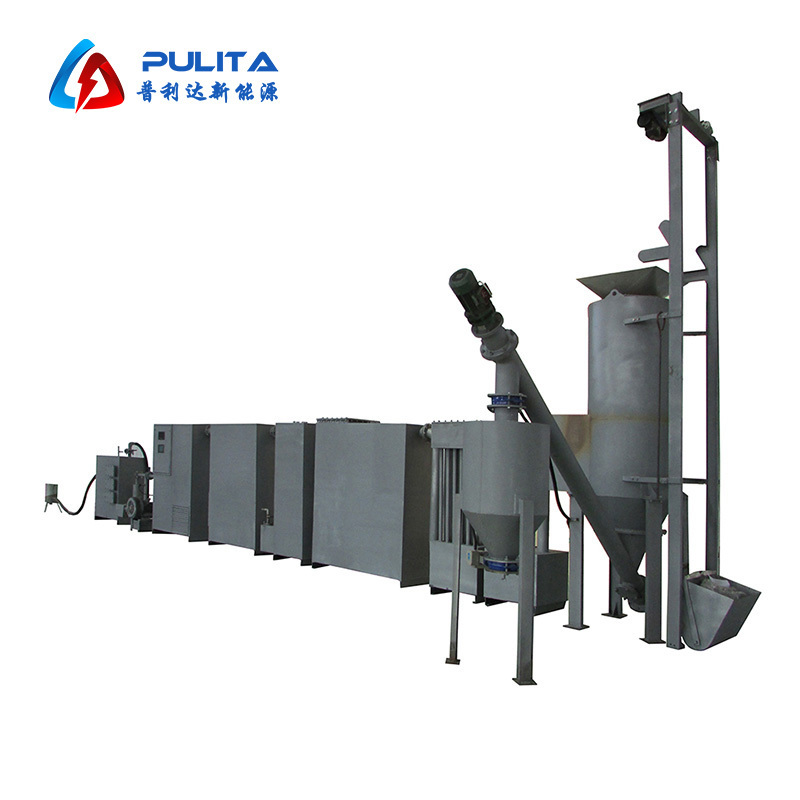

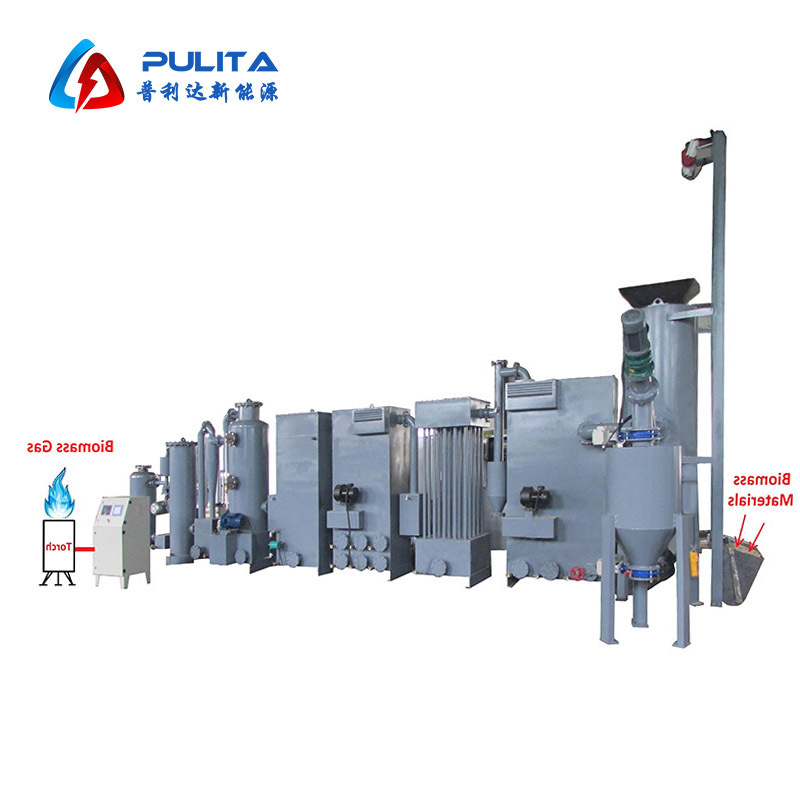

Biomass power plant industrial gasifier generator

Biomass Gasification Power Plant with Generator

Welcome to Pulita Energy !

Pulita Energy is a green and clean energy company. Pulita Energy has a long experience in producing and supplying environmentally friendly and high performing gasification systems and gas generator sets. We are specialized in biomass, coal and waste gasification to energy systems and have a company history of 7 years. Pulita Energy have since the start of 2012 been specialized in biomass gasification power plants. Our gasification energy systems can convert various types of biomass, waste or coal into electricity, process steam, drying industrial heating, district heating and etc. Pulita Energy has its own Development, Design, Construction and Project Management Departments.

Company Production Capacity

1. Advanced Gasification Technology.

2. Capacity: 10kW-1000kW ( 30m³-3000m³ ).

3. CE & IS09001:2008 Company.

4. Since 2012

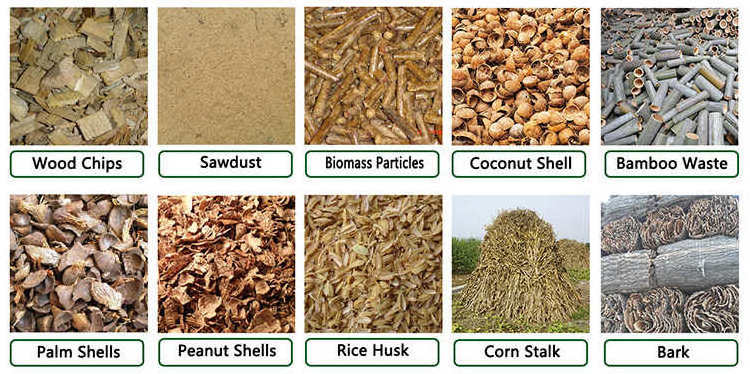

Type of Biomass & Waster can be Used in Pulita Energy Biomass Gasification System

For biomass gasification, the most important thing is that the biomass raw material contains pyrolysis gasification organic matter that is volatile. At present, the most common raw materials for biomass gasification are rice husk, wood chips, sawdust, straw, peanuts shell, corn cob, palm shell, horse manure, refuse derived fuel and so on. Different raw materials corresponding to different treatment methods and with different design of biomass gasifier, the gas composition is not the same, the calorific value is also different.

Gas Composition Data of Several Raw Materials After Gasification ( for Reference only )

| Raw Materials | Gas Content |

Heat Value (Kcal/Nm³) |

|||||

| CH 4 (%) | CO 2 (%) | CO (%) | C n H m (%) | H 2 (%) | O 2 (%) | ||

| Rice Husk | 3.16 | 15.32 | 13.69 | 0.11 | 14.55 | 0.91 | 1173 |

| Wood Chips | 2.62 | 14.86 | 17.34 | 0.09 | 18.97 | 0.72 | 1365 |

| Apricot Shell | 3.13 | 14.74 | 15.23 | 0.14 | 14.54 | 1.01 | 1221 |

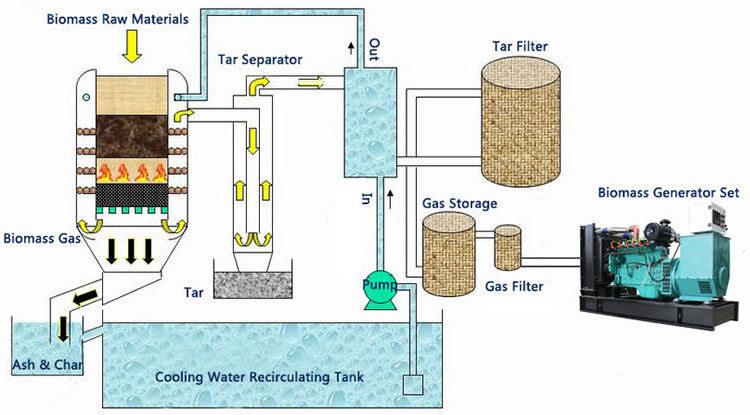

Flow Chart of Biomass Gasification Power Plant

Our biomass Gasification process includes three steps. The first step is gasification, which convert biomass into syngas. The second step is syngas purification. The producer gas coming from gasifier usually contains contamination including dust, coke, tar and etc. The contaminants will be removed by the purification system to ensure normal operation of gas engine. The third step is power generating in gas engine. The high temperature waster exhaust gas may be reused by heat boiler to generate steam or hot water for civil or industrial use.

Pictures of Biomass Gasification Power Plant

|

|

Application of Biomass Gasification Power Plant

Specification of Biomass Gasification System

Our Successful Case of Biomass Gasification System