- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1-40mm

-

Control Software:

-

Cam

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Huawei

-

Weight (KG):

-

1000 KG

-

Style:

-

Luxury

-

Color:

-

Red

-

Type:

-

Laser Cutting Stainless Steel Letters

-

Application meterial:

-

Carbon Steel Stainless Copper Metal

-

Laser power:

-

1500W / 2000W / 3000W/4000W

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

680mm/sec

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1-40mm

-

Control Software:

-

Cam

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Huawei

-

Weight (KG):

-

1000 KG

-

Style:

-

Luxury

-

Color:

-

Red

-

Type:

-

Laser Cutting Stainless Steel Letters

-

Application meterial:

-

Carbon Steel Stainless Copper Metal

-

Laser power:

-

1500W / 2000W / 3000W/4000W

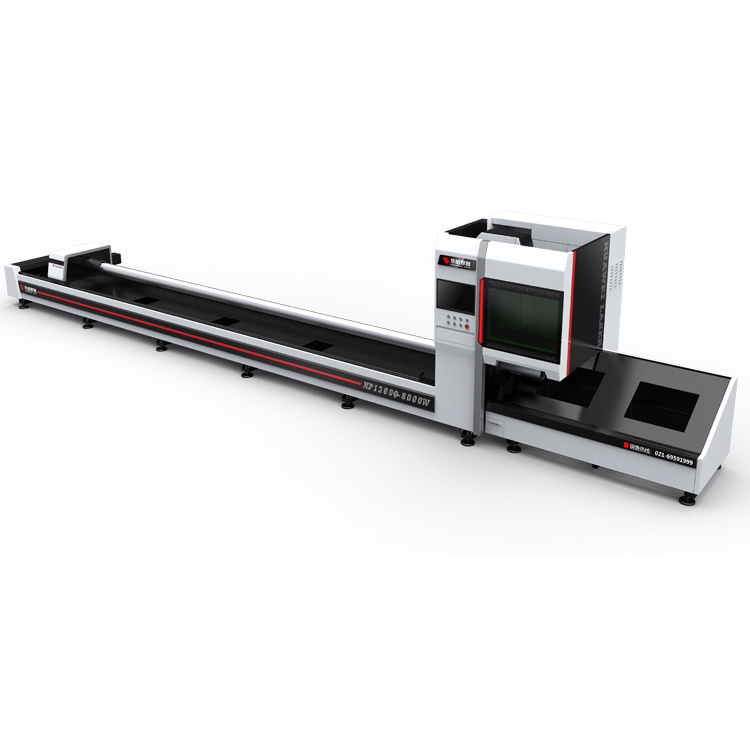

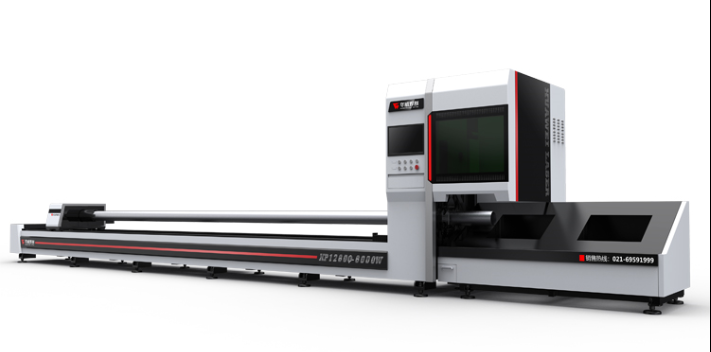

Features for fiber metal laser cutting machine

1.Metal Tube and Plate Dual Use

In order to meet the increasingly complex needs of consumers, Gweike is targeted at market demand, independently developed LF3015CR sheet and pipe integrated laser fiber cutting machine, one machine dual purpose, this machine solves double cutting needs by one time.

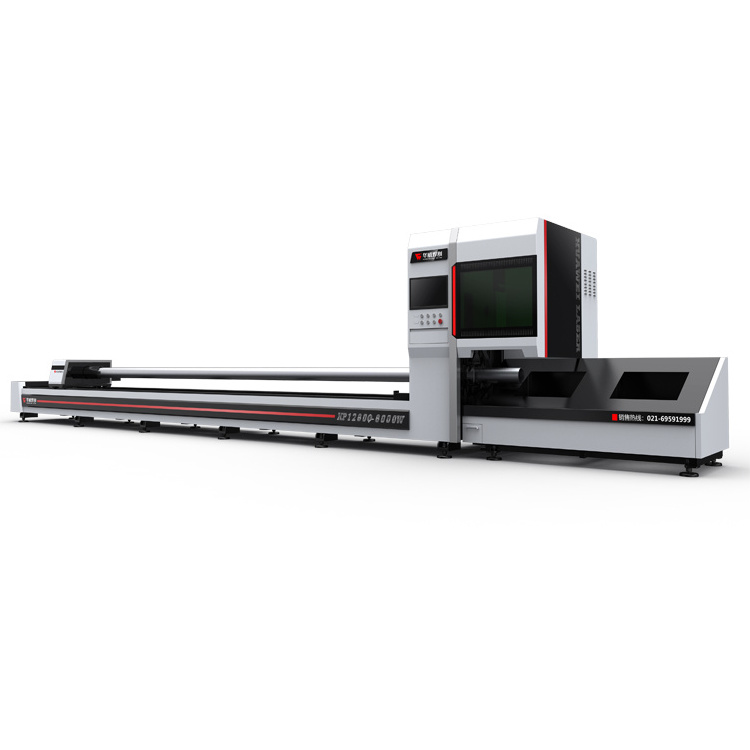

2.Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

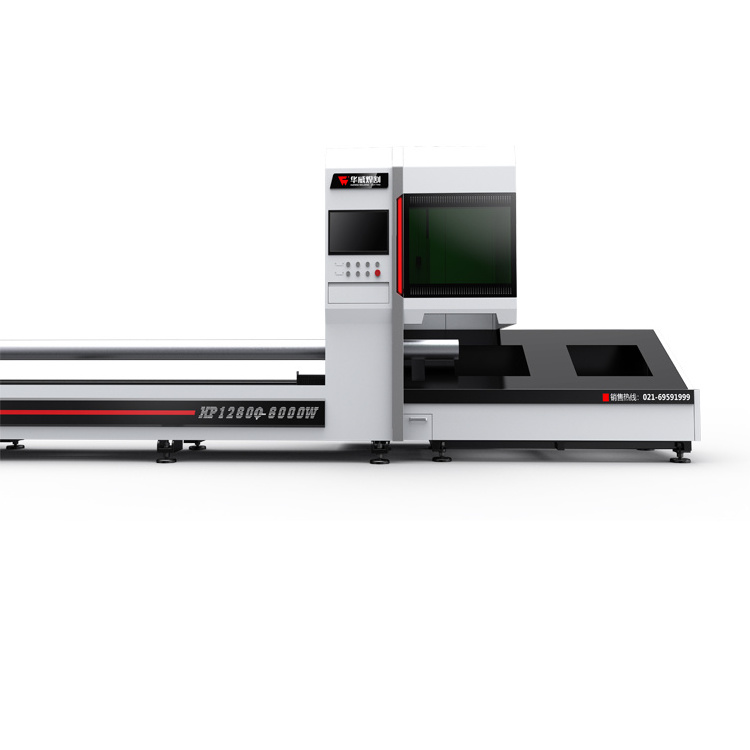

3.Exchanging Platform

It adopts an up and down exchange platform, and the converter is responsible for controlling the exchanging motor.

The machine is able to finish the platform exchanging within 15s.

4.3rd Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

5.Dual Use and Cost-saving

LF3015GCR fiber laser cutting machine can not only cut metal plates, but also metal pipes. It has many uses and can save the space of more than 50%, which effectively improve productivity.

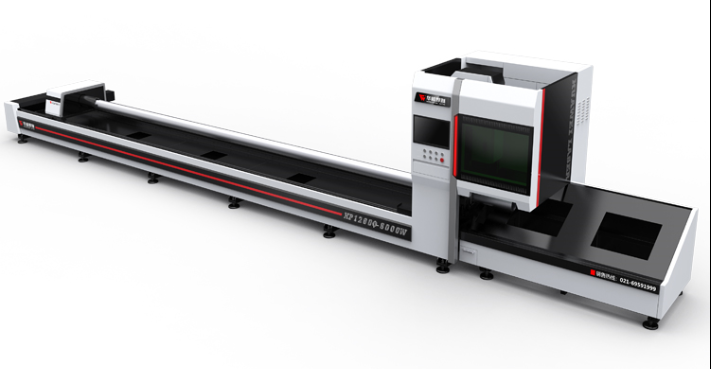

6.Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

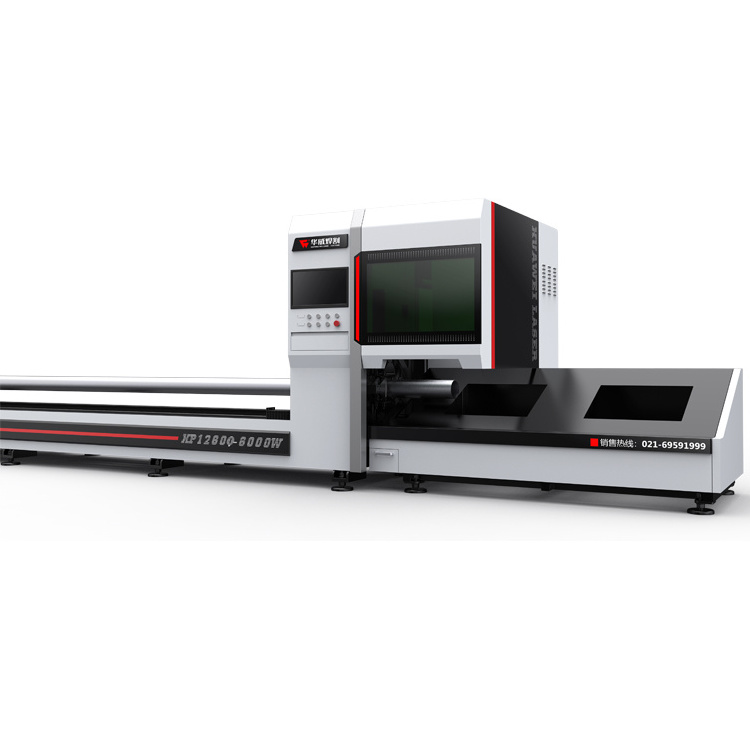

Applicable materials for laser cutting machine for metal

Fiber Laser Cutting Equipment

is suitable for metal cutting with Stainless Steel Sheet(tube), Mild Steel Plate(tube), Carbon Steel Sheet(tube), Alloy Steel Plate, Spring Steel Sheet

(tube),

, Iron Plate

(tube),

, Galvanized Iron

(tube),

, Galvanized Sheet, Aluminum Plate

(tube),

, Copper Sheet

(tube),

, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries

Fiber Laser Cutting Machine is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc

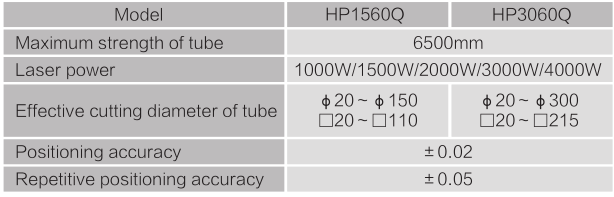

Technical Parameter

| Machine model | LF3015GCR |

| Laser type | Import original fiber laser |

| Laser power | 1000W/2000W/3000W/4000W |

| Weight | 7800kg |

| Dimensions | 4440mm×2500mm×1860mm/7800x3580x2150mm |

| Working area | 3000×1500mm/4000mm*2000mm |

| Repeat positioning accuracy | ±0.02mm |

| Maximum speed | 80m/min |

| Maximum acceleration | 1.5G |

| Transmission | Double driver rack gear |

| Power consumption | <10KW |

| Power supply | 380V/50Hz/60Hz/60A |

Quality i s our paramount mission that underpinning the lifeline of the company, and it is the most important factor to maintain long-term business relationships with customers. Special attention is paid to the quality of every unit of fiber laser cutting machine . Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser power meter. The laser interferometer and laser collimator are used through the mechanical assembling process. In the laser assembling process,the laser power meter and optical microscope are adopted.