1. Design plan: Our company has a professional kiln design company, and the designers have more than 20 years of kiln design experience. After the drawings are completed, experts will finalize the drawings to ensure the construction of the kiln.

2. Construction drawing: Mark the size of each place on the construction drawing, and indicate the name, specification and quantity of the refractory materials used. Any experienced construction personnel can understand the drawings and follow the construction without making mistakes.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

250

-

Dimension(L*W*H):

-

180*1.2*3.4m

-

Weight (T):

-

50 T

-

Power (kW):

-

100000

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product Name:

-

tunnel kiln repaired and building

-

Working Temperature:

-

1180-1250

-

Feature:

-

Energy-saving

-

Capacity:

-

10kg~50ton

-

Heating rate:

-

85%

-

Vacuum system:

-

Vacuum Pump

-

Frequency:

-

10

-

Duty cycle:

-

100% 24H Continuous Work

-

Loading capacity:

-

10~3000kg (adjustable)

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product

-

Brand Name:

-

Lite

-

Voltage:

-

250

-

Dimension(L*W*H):

-

180*1.2*3.4m

-

Weight (T):

-

50 T

-

Power (kW):

-

100000

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product Name:

-

tunnel kiln repaired and building

-

Working Temperature:

-

1180-1250

-

Feature:

-

Energy-saving

-

Capacity:

-

10kg~50ton

-

Heating rate:

-

85%

-

Vacuum system:

-

Vacuum Pump

-

Frequency:

-

10

-

Duty cycle:

-

100% 24H Continuous Work

-

Loading capacity:

-

10~3000kg (adjustable)

|

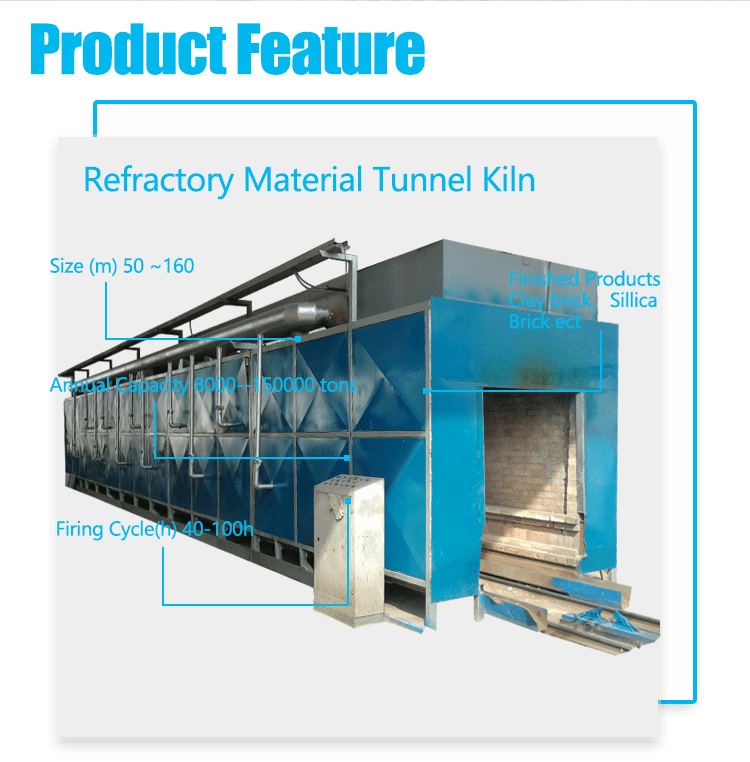

Kiln name

|

size

|

width

|

Firing temperature

|

Firing cycle

|

Fuel consumption

|

Annual production

|

|

Metallurgicalpowder tunnel kiln

|

110-220m

|

1.85-3.5

|

1080-1180

|

50-60

|

1300-1400

|

8000-50000t

|

|

Refractory tunnel kiln

|

60-180m

|

1.2-3.4

|

1150-1750

|

40-200

|

1000-1800

|

5000-30000t

|

|

Sanitary porcelain

tunnel kiln

|

20-150m

|

0.85-4.0

|

1150-1280

|

11-16

|

1200-1500

3000-6000

|

100000-1200000pieces

|

|

Daily porcelaintunnel kiln

|

40-110m

|

1.0-3.0

|

1260-1420

|

14-25

|

1800-2500

4000-5000

|

2000000-15000000pieces

|

|

Building bricktunnel kiln

|

60-160m

|

3.9-6.9

|

1050-1250

|

16-56

|

450-800

650-900

|

2000000-80000000pieces

|

|

Electric porcelain

tunnel kiln

|

40-120m

|

1.5-2.5

|

1080-1250

|

50-80

|

5000-6000

|

-

|

|

other products high temperature

tunnel kiln

|

40-110m

|

1.3-3.0

|

1300-1700

|

45-70

|

3500-7000

|

According to specific products

|

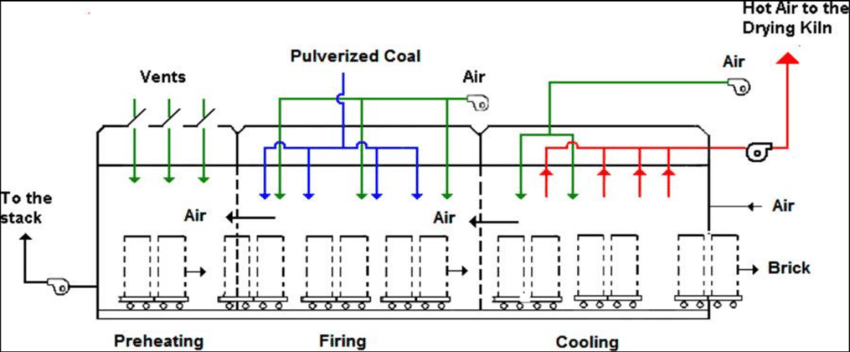

Drawing design

Construction procedure

1.Underground part:

Total flue, inspection tunnel and tunnel kiln foundation.

2.Track installation:

Install the kiln inner track, make a model car, and water the secondary concrete.

3.Kiln wall:

The kiln wall is built up to the arch bricks, including the installation of sand sealing grooves and sand pipes.

4.Install the fan:

Cast the fan foundation and install all the gates of the fan and kiln.

Construction procedure

5.kiln arch:

Brickwork arches and some walls and dense tops above the arched bricks;

6.Installation of kiln outer track:

Installation of kiln outer track, trolley machine, return winch, kiln door, etc.;

7.Kiln lining brick:

Masonry kiln car lining brick;

8.Inspection:

Comprehensive inspection, cleaning, and preparation for delivery acceptance.

Acceptance and trial

1. Conduct a comprehensive inspection of the appearance quality of the kiln masonry to see if there is any crack, settlement or deformation phenomenon;

2. Remove the foreign matter in the air passage, the air outlet, the pedestrian hole, the sand sealing groove, the sanding pipe, the inspection well, the inspection road, and the outer wall and the brick column and the expansion joint;

Acceptance and trial

3. Whether the expansion joint is filled with insulation material, and whether the closed hole should be closed tightly ;

4. Whether the sand sealing groove is added to the sand according to the regulations;

5. Whether the mechanical kiln door and the damper lift are flexible, and whether the closing is tight and airtight.

Daily production of 600 tons of activated lime rotary kiln

This series of kilns is an ideal sintering equipment of active lime in China, with high output, high activity, suitable for steelmaking. It is capable of burning oil, burning gas and burning coal. The daily output is 80 tons -600 tons, and the technology is mature and reliable. Maximum service temperature 1050-1100 degrees Celsius

120 cubic meters electric porcelain shuttle kiln

200 cubic meters hot blast stove

Annual production of 20 thousand tons of high alumina brick production line

200 cubic meters hot blast stove

Q1.Can we visit your company?

A1:Sure,welcome at any time,seeing is believing.

Q2.What's the MOQ of trial order?

A2:No limit,We can offer the best suggestions and solutions according to your condition.

Q3.What are the payment terms?

A3:Usually T/T,but L/C,Western Union etc are available for us.

Q4. How long is delivery time?

A4:The delivery time will be determined according to the quantity of the order.

Q5.How are your products' quality?

A5:The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q6.How to slove the quality problems?

A6:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7.How about your company's certification?

A7:ISO9001 and Test Report,also we could apply other necessary certification.