- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1560*1560*5230 mm

-

Weight:

-

600 KG, 600 kg

-

Product name:

-

Spiral Concentrator, Spiral Chute,Gravity Seprator

-

Spitch:

-

540 or 900 mm

-

Size of feeding ore:

-

<4 mm

-

Feeding density:

-

25% to 35%

-

Capacity per hour:

-

4 to 6 tons per hour

-

Diameter:

-

1200 mm

-

Installation:

-

Supply you detailed installation Steps in videos, photos and words

-

Certification:

-

ISO, CE,SGS

-

Application area:

-

Gold, Coal, ilmenite, iron, tin, chromite, tungsten

Quick Details

-

Production Capacity:

-

4-6 t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Yongsheng

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1560*1560*5230 mm

-

Weight:

-

600 KG, 600 kg

-

Product name:

-

Spiral Concentrator, Spiral Chute,Gravity Seprator

-

Spitch:

-

540 or 900 mm

-

Size of feeding ore:

-

<4 mm

-

Feeding density:

-

25% to 35%

-

Capacity per hour:

-

4 to 6 tons per hour

-

Diameter:

-

1200 mm

-

Installation:

-

Supply you detailed installation Steps in videos, photos and words

-

Certification:

-

ISO, CE,SGS

-

Application area:

-

Gold, Coal, ilmenite, iron, tin, chromite, tungsten

Product Description

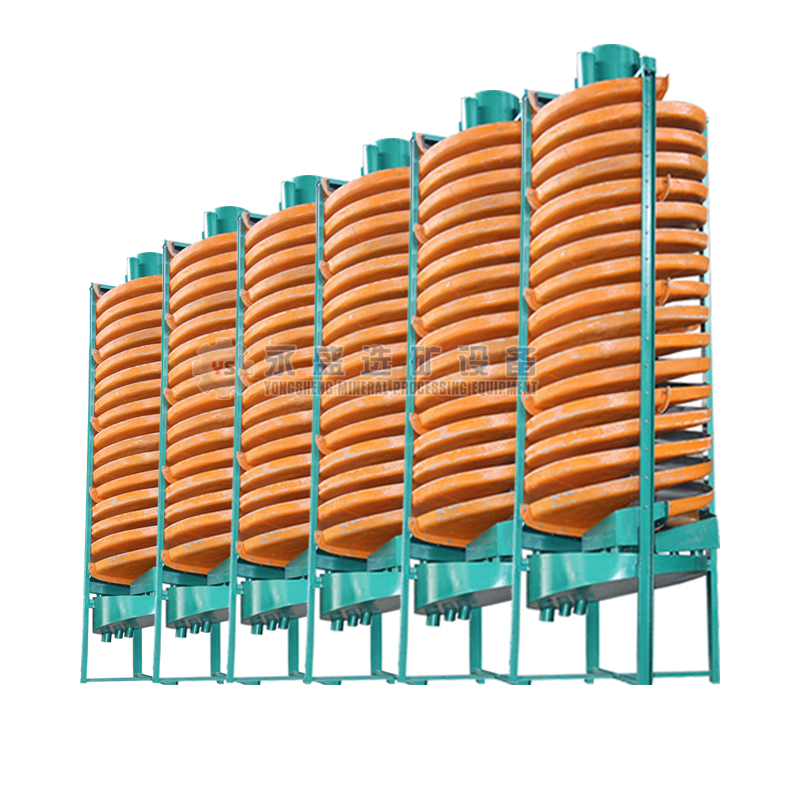

2023 New product sand gold washing plant spiral chute gravity separator machine coal processing plant 2-4 mm size for sale

Gravity Spiral Chute concentrator separator is our company’s concentrating experienced scientific product, which is the best concentrating equipment, especially for concentrating sand ore in beach, riverside, seashore and stream. Also has been used in to enrichment the particle size 0.3-4mm fine grain like iron, tin, chromite, ilmenite, tungsten, zinc, tantalum-niobium, gold, coal, monazite, rutile, zircon and other low-grade ores. The non-metallic minerals which have a big enough specific gravity difference.

The product is made of the fiberglass lined with wear-resistant resin and cover emery; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new highly effective equipment.

Gravity Spiral Chute concentrator separator is working under the the force of water flow, gravity, inertial centrifuge and

friction. Slurry is pumped to the top of the spiral , and it enters a feed distributor that evenly distributes the feed to each

Spiral Chute. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles are carried with the bulk of the water towards the outside of the spiral , while particles with the greatest density migrate towards the inside of the spiral.

Features of Price for Gravity Spiral chute concentrator separator:

1. Reasonable structure and small area occupation

2. High recovery, high efficiency, and precise separation

3. Non-required power

4. Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of emery forms strong friction the concentration effect surpass plastic surface

Specification

|

Model

|

|

5LL-2000

|

5LL-1500

|

5LL-1200

|

5LL-900

|

5LL-600

|

5LL-400

|

|

|

Outside Dia. (mm)

|

|

2000

|

1500

|

1200

|

900

|

600

|

400

|

|

|

Pitch (mm)

|

|

1200

|

800,680,540

|

720,540,360

|

660,540,400

|

450,360,270

|

240,180

|

|

|

Lateral slope

|

|

9°

|

9°

|

9°

|

9°

|

9°

|

9°

|

|

|

External size |

Length (mm)

|

2300

|

1560

|

1360

|

1060

|

700

|

460

|

|

|

|

Width (mm)

|

2300

|

1560

|

1360

|

1060

|

700

|

460

|

|

|

|

Height (mm)

|

6500

|

5230

|

5230

|

4000

|

2600

|

1500

|

|

|

Starts/Turns per column

|

|

4-2

|

4-2

|

4-2

|

4-2

|

2

|

2

|

|

|

Feeding size (mm)

|

|

4-0.04

|

0.8-0.037

|

0.3-0.03

|

0.3-0.03

|

0.2-0.02

|

0.2-0.02

|

|

|

Feeding density (%)

|

|

20-45

|

30-60

|

25-55

|

25-55

|

25-55

|

25-55

|

|

|

Capacity (t/h)

|

|

12-10

|

8-6

|

4-6

|

2-3

|

0.8-1.2

|

0.15-0.2

|

|

|

Weight (KG)

|

|

1100

|

800

|

600

|

400

|

150

|

50

|

|

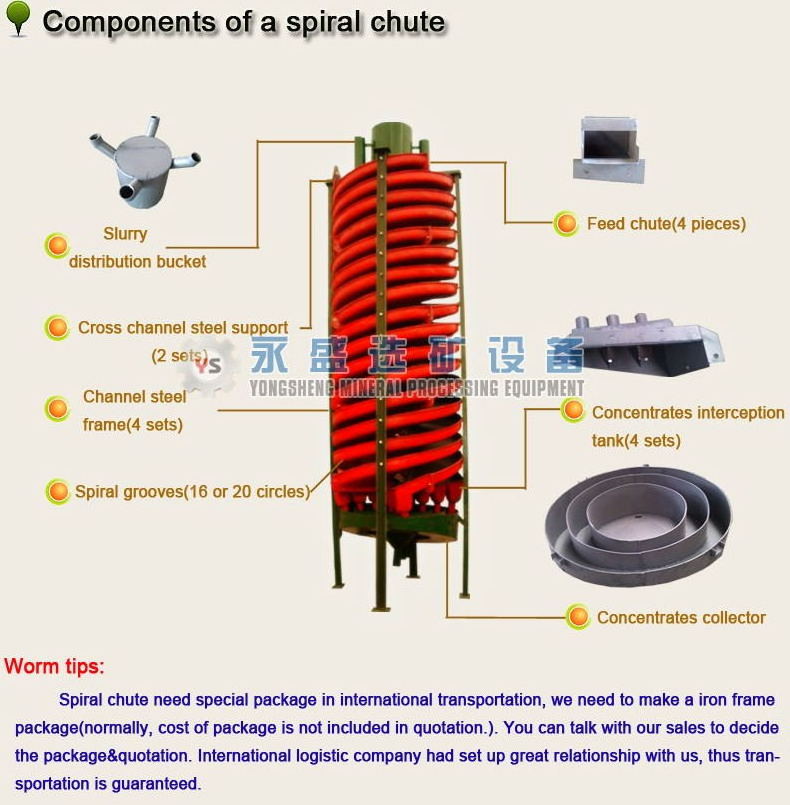

Product Stucture

Details Images

Part 01

Name: Spiral Grooves

Material: Fiberglass (Glass fibre reinforced plastic)

Part 02

Name: Slurry Distribution Bucket

Name: Spiral Grooves

Material: Fiberglass (Glass fibre reinforced plastic)

Part 02

Name: Slurry Distribution Bucket

Material: Q235 STEEL OR PVC

Normally, one set spiral concentrator has four starts, each starts has four or five spiral grooves.Therefore, when ore come into the spiral chute, we use the distributor bucket.

Normally, one set spiral concentrator has four starts, each starts has four or five spiral grooves.Therefore, when ore come into the spiral chute, we use the distributor bucket.

Part 03

Name: Concentrates Interception Tank with Wood Valve

To adjust concentrates percent or recovery of ore

Material: Q235 STEEL OR PVC

Part 04

Name: Concentrates Collector ( Receiver)

Material: Q235 STEEL OR PVC

Name: Concentrates Interception Tank with Wood Valve

To adjust concentrates percent or recovery of ore

Material: Q235 STEEL OR PVC

Part 04

Name: Concentrates Collector ( Receiver)

Material: Q235 STEEL OR PVC

Each starts come out with three results, they are concentrates, middling, tailing. In order to make four starts output material be divide in right way, so the Collector works.

Packing & Delivery

Packing : For Mineral Spiral Chute Separator.

If One 20ft container, can put 6 sets common type Model 5LL-1200 Spiral chute separator. 3-4 sets 5LL-1500.

if one 40 HQ can loading in 18-20 sets Model 5LL-1200 Spiral chute Separator and 8-10 sets 5LL-1500.

Delivery : Within 10 days after recieved 30% advance payment.

Payment terms : Pay T/T 30% in advance, the balance 70% should be paid before the products delivery out of Factory.

Delivery : Within 10 days after recieved 30% advance payment.

Payment terms : Pay T/T 30% in advance, the balance 70% should be paid before the products delivery out of Factory.

Company Profie

Q: What is the payment terms ?

A: 1.30% prepayment by T/T , after the seller finish the production process and buyer verify the machine , 70% balance should paid before delivery.

2. .Alibaba trade assurance L/C is also acceptable in special conditions.

Q: How long is the delivery time of your machine?

A: 1. The delivery time is within 7-30 working days.

2. But if the project is very large and clients have some special requirement about the equipment, the delivery time will be

extend.

Q: How long will the shipment takes ? (roughly)

A: 1. Africa : 30-45 days

Asia : 5-25 days

America : 15-40 days

Europe : 30-40 days

Q: How long is the warranty period about machine?

A: 1. Our machine warranty period is 1 year.

2. Wearing parts and problem coursed by worker's wrong operation are not included.

Q: Can you provide me a solution and quotation?

A: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage of final products, etc.

A: 1.30% prepayment by T/T , after the seller finish the production process and buyer verify the machine , 70% balance should paid before delivery.

2. .Alibaba trade assurance L/C is also acceptable in special conditions.

Q: How long is the delivery time of your machine?

A: 1. The delivery time is within 7-30 working days.

2. But if the project is very large and clients have some special requirement about the equipment, the delivery time will be

extend.

Q: How long will the shipment takes ? (roughly)

A: 1. Africa : 30-45 days

Asia : 5-25 days

America : 15-40 days

Europe : 30-40 days

Q: How long is the warranty period about machine?

A: 1. Our machine warranty period is 1 year.

2. Wearing parts and problem coursed by worker's wrong operation are not included.

Q: Can you provide me a solution and quotation?

A: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage of final products, etc.

Contact Me

Hot Searches