- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ATMARS, ATMARS

-

Model Number:

-

AS2-800A, AS2-800A

-

Product name:

-

Thermal shock chamber two zone

-

High temperature shock range:

-

+60°C~+150°C

-

Low temperature shock range:

-

-40°C~+-10°C

-

Power supple:

-

AC/380V±10%,50Hz,≤15Kw,3 phase5 wires

-

Test area capacity:

-

800L

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China, Guangdong, China

-

Brand Name:

-

ATMARS, ATMARS

-

Model Number:

-

AS2-800A, AS2-800A

-

Product name:

-

Thermal shock chamber two zone

-

High temperature shock range:

-

+60°C~+150°C

-

Low temperature shock range:

-

-40°C~+-10°C

-

Power supple:

-

AC/380V±10%,50Hz,≤15Kw,3 phase5 wires

-

Test area capacity:

-

800L

Product descriptions from the supplier

Product Parameters

|

Model

|

|

|

AS2-800A

|

|

|||

|

Temperature humidity adjustment mode

|

|

|

Smart balanced temperature(humidity) control - BT(H)C

|

|

|||

|

Test area capacity

|

|

|

800L

|

|

|||

|

Workspace dimensions

(WxHxD)mm

|

|

|

1000*100*800

|

|

|||

|

Exterior dimensions

(WxHxD)mm

|

|

|

2440*2370*2300

|

|

|||

|

Temperature

Performance

|

High temperature shock range

|

|

+60℃ to +150℃

|

|

|||

|

|

Low temperature shock range

|

|

-40℃ to -10℃

|

|

|||

|

|

Hot zone Temperature setting range

|

|

+60℃ to +200℃

|

|

|||

|

|

Cold zone Temperature setting range

|

|

-65℃ to -10℃

|

|

|||

|

|

Shock recovery time

|

|

-40℃ to +150℃ about 5min

|

|

|||

|

|

Transfer time

|

|

≤10sec

|

|

|||

|

|

High and low

temperature impact constant temperature time |

|

more 30 min

|

|

|||

|

|

Temperature uniformity

|

|

±2.0℃

|

|

|||

|

|

Temperature fluctuation

|

|

±0.5℃

|

|

|||

|

|

Load(KG)

|

|

30

|

|

|||

|

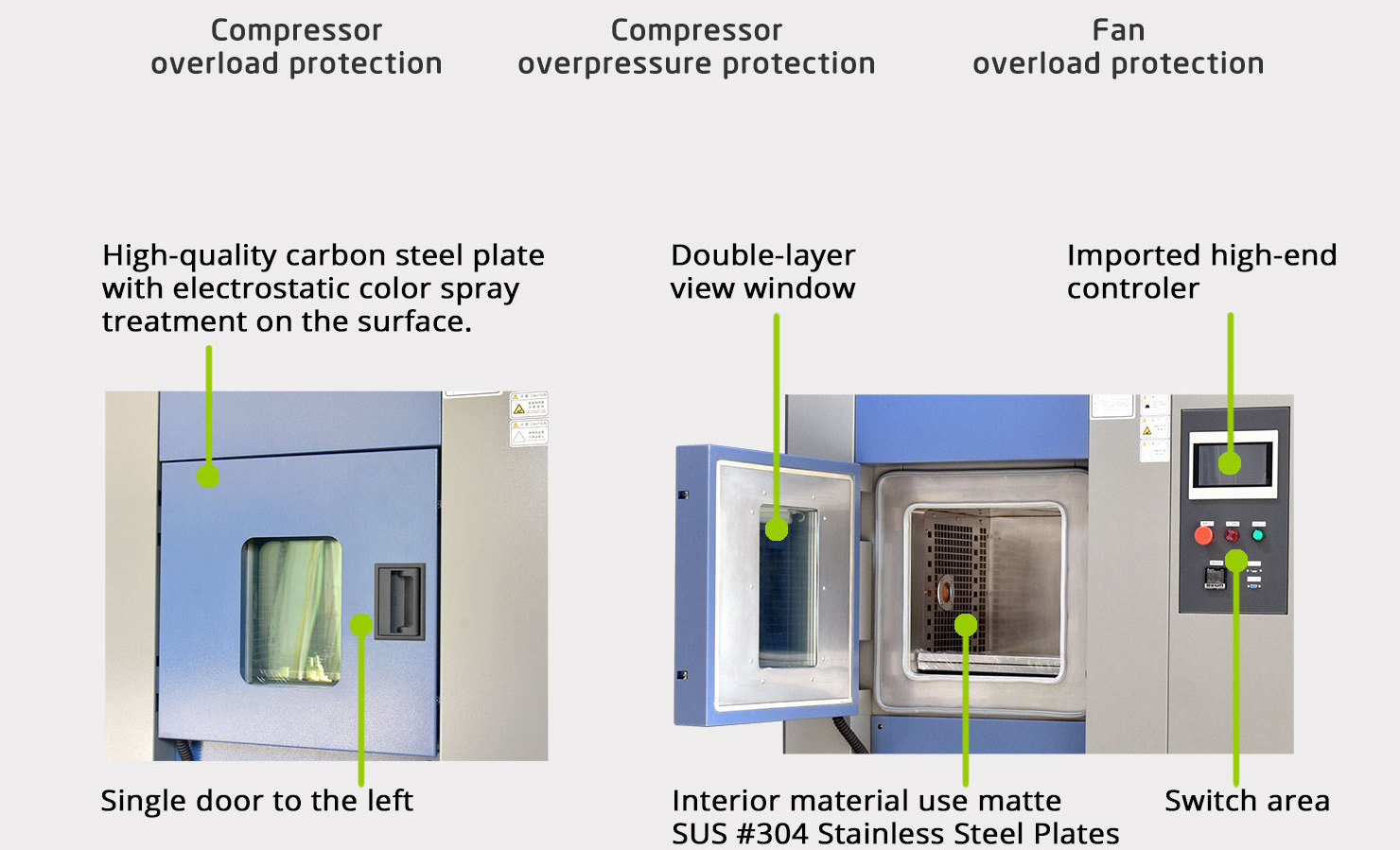

Material

|

Interior

|

|

Matte SUS #304 Stainless Steel Plates

|

|

|||

|

|

Exterior

|

|

Powder Coated Carbon Steel Plates

|

|

|||

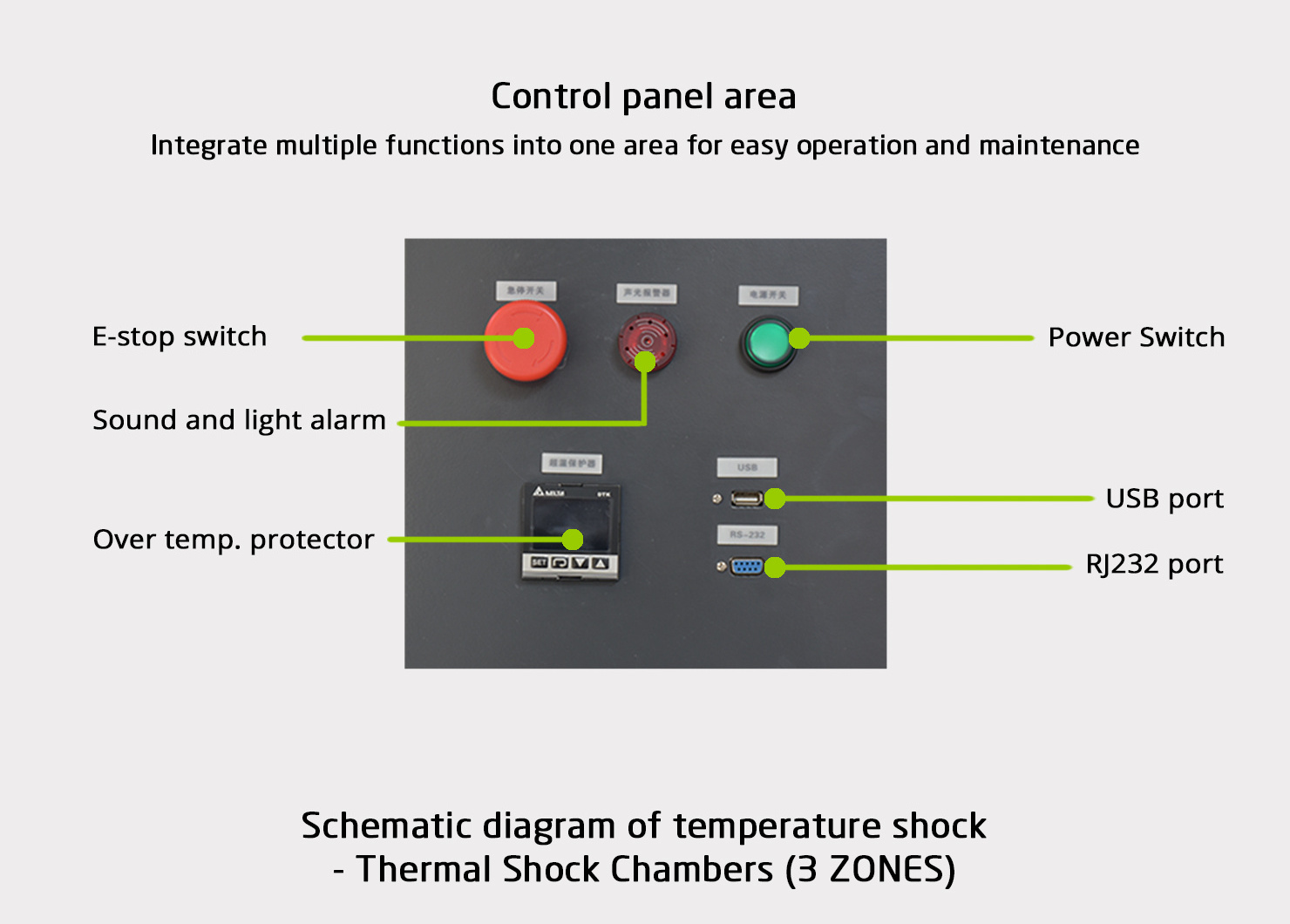

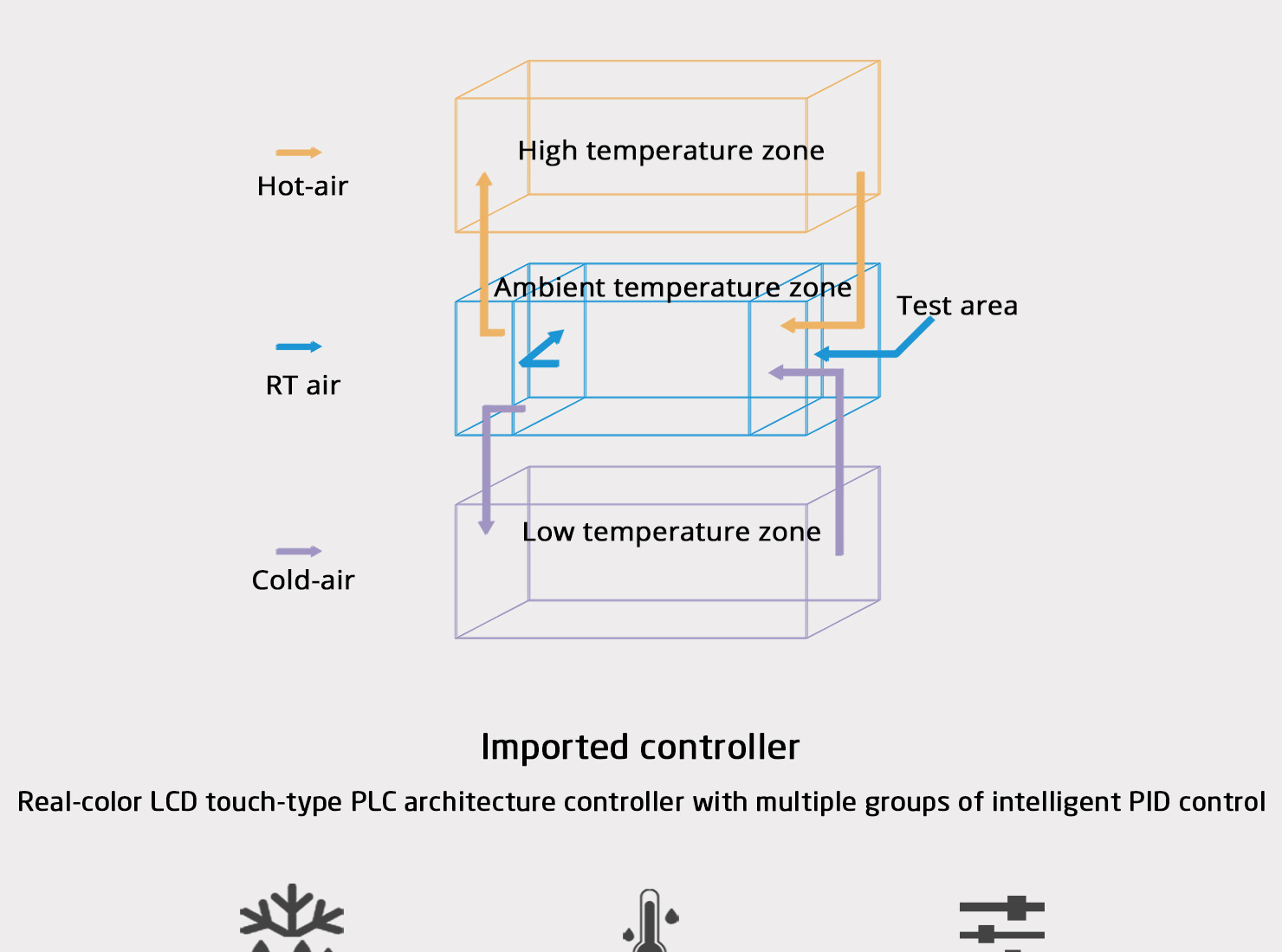

Product Description

Product Presentation:

The thermal shock test chamber (two-zone) is an experimental equipment that simulates the rapid temperature change in nature.The physical and chemical damage suffered, so as to find the quality problems of the product, and then improve and optimize it. Thermal shock test chamber (two- zone) is used for photovoltaic modules, LED tubes and lamps, electronic and electrical components, automation components, communication components, auto parts, metals, chemical materials, plastics and other industries, testing the repeated resistance of its materials to high and low temperatures and the chemical changes or physical damage of the products produced by thermal expansion and contraction can confirm the product quality.

Product Features :

Design is constructed of two independently controlled chambers. One chamber is hot and the other one is cold. Product is rapidly transferred between the hot and cold chamber creating a temperature shock of the specimens.

Hot Searches