- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220-380V

-

Power:

-

50-60HZ

-

Dimension(L*W*H):

-

to be confirmed

-

Weight (KG):

-

400

-

Name:

-

Fluidizing bed powder coating machine

-

Material:

-

Stainess Steel

-

size:

-

W2200*H1500*1400mm, can be customized

-

Inner fluidizd plate:

-

2200*1400*20 mm

-

Standard configuration:

-

1 centrifugal fan, 5 filters

-

Fan motor:

-

4kw

Quick Details

-

Machine Type:

-

Fluidizing bed powder coating, Coating Equipment

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Kafan

-

Voltage:

-

220-380V

-

Power:

-

50-60HZ

-

Dimension(L*W*H):

-

to be confirmed

-

Weight (KG):

-

400

-

Name:

-

Fluidizing bed powder coating machine

-

Material:

-

Stainess Steel

-

size:

-

W2200*H1500*1400mm, can be customized

-

Inner fluidizd plate:

-

2200*1400*20 mm

-

Standard configuration:

-

1 centrifugal fan, 5 filters

-

Fan motor:

-

4kw

Product Description

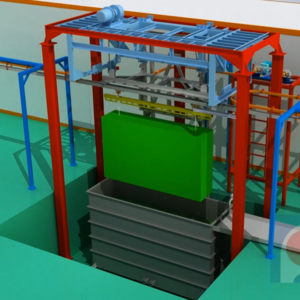

Dip Coating Machine Fluidizing Bed powder coating Equipment

Fluidized bed dipping powder coating equipment is a type of coating application system that uses a fluidized bed to evenly coat a substrate with a powder coating material. The object is pre-heated to a temperature above the melting point of the powder. The object is then submerged in or in the cloud just above the fluidized bed of powder. The powder melts and forms a coating onto the hot surface.

It is particularly useful for coating complex parts that may be difficult to coat using other methods.

It is particularly useful for coating complex parts that may be difficult to coat using other methods.

Fluidizing Bed powder coating Equipment Feature

1) Fluidized bed dipping equipment with powder recovery system, the powder recovery rate is high.

2) No dust spillover, which can reduce material waste and lower coating costs.

3) Because the powder coating material is fluidized and evenly distributed in the bed, the resulting coating is typically uniform in thickness and appearance.

4) High efficiency, the fluidized bed dipping process can be automated, allowing for high-volume production with minimal operator intervention.

5) The coating layer has excellent chemical resistance, anti-aging, impact resistance, bending resistance, acid resistance, salt spray corrosion resistance, and has good surface decorative properties.

3) Because the powder coating material is fluidized and evenly distributed in the bed, the resulting coating is typically uniform in thickness and appearance.

4) High efficiency, the fluidized bed dipping process can be automated, allowing for high-volume production with minimal operator intervention.

5) The coating layer has excellent chemical resistance, anti-aging, impact resistance, bending resistance, acid resistance, salt spray corrosion resistance, and has good surface decorative properties.

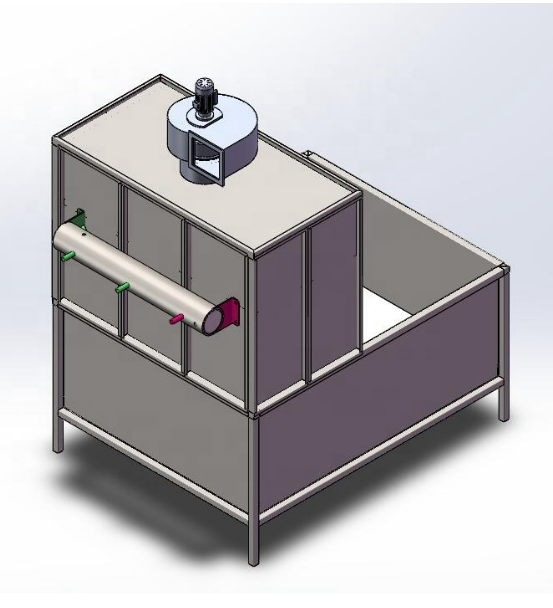

Details Images

Circulating Fan and Filter

Fluidized Bed Internal

Fluidized bed dipping equipment with powder coating booth recovery system, so excess powder coating material can be recycled and reused, reducing waste and minimizing the impact on the environment.

Electric control box

Water separator

Specification

|

Modle

|

Fluidizing Bed powder coating Equipment

|

|

material

|

Stainless steel plate

|

|

Working size

|

W2200*H1500*1400mm, can be customized

|

|

Inner fluidizd plate

|

2200*1400*20 mm

|

|

Standard configuration

|

1 centrifugal fan, 5 filters

|

|

fan motor

|

4KW

|

|

Filter size

|

325*600mm

|

|

Rated voltage:

|

380V 3phase(Or customized voltage)

|

Application

The fluidized bed powder coating equipment is used in various industries, such as aluminum profile, furniture, and metal frameetc. It provides a high-quality, durable, and uniform coating on the surface of the object being coated.

Recommend Products

Packing & Delivery

Hot Searches