The shredder machine can easily pre-crush:

•plastic sheets;

•electronic waste;

•scrap (components, subassemblies; consumables);

•metals(lead, aluminum, copper, cable, barrels, sheet scrap, sheet metal pieces left over from production processes);

•aluminum cans;

•wood(wooden pallets or fruit boxes);

•plastic(plastic bottles or canisters);

•waste tire, rubber;

•waste household appliances;

•paper waste (cardboard, newspaper, office paper, books, magazine, kraft paper, paper core, cardboard tube, paper packaging

material);

•textiles (rags, garments, carpet);

•animal bones and organic waste.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fante

-

Voltage:

-

380/50/3 or customized

-

Dimension(L*W*H):

-

See technical parameter

-

Power (kW):

-

3

-

Weight (T):

-

0.5

-

Application:

-

Recycle Waste Plastic

-

Name:

-

shredder

-

Usage:

-

plastic/wood/rubber/paper/metal and etc.

-

Color:

-

Client's Requirements

-

Crushing material:

-

Types Waste Plastic

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Other name:

-

Double Shaft Plastic shredder

-

Final product:

-

1-10 Cm

-

Function:

-

Waste Plastic Crusher

Quick Details

-

Max.Production Capacity (kg/h):

-

300

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

50 - 300 kg/h

-

Brand Name:

-

Fante

-

Voltage:

-

380/50/3 or customized

-

Dimension(L*W*H):

-

See technical parameter

-

Power (kW):

-

3

-

Weight (T):

-

0.5

-

Application:

-

Recycle Waste Plastic

-

Name:

-

shredder

-

Usage:

-

plastic/wood/rubber/paper/metal and etc.

-

Color:

-

Client's Requirements

-

Crushing material:

-

Types Waste Plastic

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Other name:

-

Double Shaft Plastic shredder

-

Final product:

-

1-10 Cm

-

Function:

-

Waste Plastic Crusher

|

Model

|

FT2S-1000

|

FT2S-1500

|

FT2S-2000

|

|

Motor

|

22KW*2

|

55KW*2

|

90KW*2

|

|

Weight(KG)

|

5200

|

9000

|

20100

|

|

Tool size( mm)

|

Φ300*40

|

Φ550*50/75

|

Φ600*50/75

|

|

Number of tools( pcs)

|

24

|

30/20

|

40/26

|

|

Feed port size( mm)

|

1000*690

|

1500*850

|

2000*1490

|

|

Dimension (mm)

|

3300*1900*2200

|

2800*2800*2100

|

3000*2800*2100

|

Application Areas:

Technical Features:

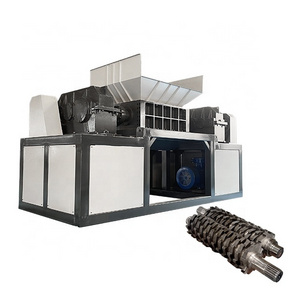

1. Our shredders can be employed as either a primary or secondary shredder and can be seen working anywhere from the waste management company to biofuel producers;

2. Dual shafted, slow-speed, high-torque waste shredder with hardened steel cutters;

3. The two cutting rotors powerfully grab the feed material, and no matter the feed material is large piece of hard plastic or heavy tires, this machine can easily shred them into small pieces;

4. Double shaft shredder is able to process a number of different materials; shredder is designed with a powerful engine, long working length and aggressive input, Internal feeding volume bigger than traditional and common single shaft shredder machine and allow you using forklift truck to feed.

5. Heavy structure: the frame and structure of our shredders are made of high-thickness sheets and tubular. Blades are manufactured from high quality steel, suitable for shredding tough materials and for extra long life;

6. Depending on requirement, these discs (blades) are available in a wide range of quantities, qualities and shapes with the new double-shaft shredder;

7. Any overloads caused by foreign material are sensed by the PLC controller and cause the shaft rotation to stop and reverse direction to clear the foreign matter, and then resume;

8.Cutters removal and replacement can be carried out safely and simply.

9. Our shredders Use a planetary reducer, not a traditional gearbox, and the planetary gearbox has the following advantages: High Efficiency, Greater Stability, Compact Size, Higher Torque Density, Cost Effective Precision, High Radial Loads.

10. Cooler system(optional) can maintain the temperature for continuous operation. .

2. Dual shafted, slow-speed, high-torque waste shredder with hardened steel cutters;

3. The two cutting rotors powerfully grab the feed material, and no matter the feed material is large piece of hard plastic or heavy tires, this machine can easily shred them into small pieces;

4. Double shaft shredder is able to process a number of different materials; shredder is designed with a powerful engine, long working length and aggressive input, Internal feeding volume bigger than traditional and common single shaft shredder machine and allow you using forklift truck to feed.

5. Heavy structure: the frame and structure of our shredders are made of high-thickness sheets and tubular. Blades are manufactured from high quality steel, suitable for shredding tough materials and for extra long life;

6. Depending on requirement, these discs (blades) are available in a wide range of quantities, qualities and shapes with the new double-shaft shredder;

7. Any overloads caused by foreign material are sensed by the PLC controller and cause the shaft rotation to stop and reverse direction to clear the foreign matter, and then resume;

8.Cutters removal and replacement can be carried out safely and simply.

9. Our shredders Use a planetary reducer, not a traditional gearbox, and the planetary gearbox has the following advantages: High Efficiency, Greater Stability, Compact Size, Higher Torque Density, Cost Effective Precision, High Radial Loads.

10. Cooler system(optional) can maintain the temperature for continuous operation. .

Frequently asked questions when buying products

Q: How many years have your factory been established?

A:Our factory established from 2015, but most of our engineers are workingin this industry over 20 year.

Q: How long is your delivery time ?

A:we have a few stock .but if produce,1 set for normal machine need about 3-7 working days , if 1 or more containers, need about 15-20 working days.

Q:how long is the warranty?

A:Within 1 year from date of the factory, if parts failure or damage(because of the quality problem ,except wearing parts),our company provide these parts for free.

Q:What is your payment term ?

A:TT 100% before shipment ,LC at sign, Western Union or Trade Assurance order recommended.

Hot Searches