- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3.668*3.668*8.070m

-

Weight:

-

3.844t

-

Key Selling Points:

-

Easy to install

-

Name:

-

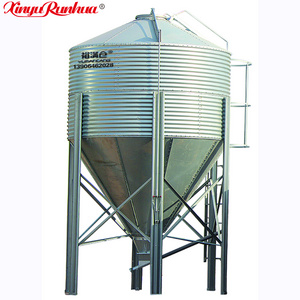

steel sesame storage silo for sale

-

Usage:

-

silo for corn seed storage

-

Production standard for small silo:

-

Chinese/Austrilia/America standard

-

Brand name:

-

Shelley Silo

-

Silo type:

-

Assembly small hopper steel silo

-

Handling equipments:

-

bucket elevator/conveyor/cleaner/dryer/fumigating system etc.

-

Safety inspection device:

-

temperature/moisture inspection sensors for corn seed silos

-

Silo Materials:

-

Hot-dip galvanized steel sheet

-

Certification:

-

ISO BV CE for seed silos bins

-

Galvanized coating:

-

275g/m2

Quick Details

-

Core Components:

-

Water-proof Silo Roof

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TSE

-

Dimension(L*W*H):

-

3.668*3.668*8.070m

-

Weight:

-

3.844t

-

Key Selling Points:

-

Easy to install

-

Name:

-

steel sesame storage silo for sale

-

Usage:

-

silo for corn seed storage

-

Production standard for small silo:

-

Chinese/Austrilia/America standard

-

Brand name:

-

Shelley Silo

-

Silo type:

-

Assembly small hopper steel silo

-

Handling equipments:

-

bucket elevator/conveyor/cleaner/dryer/fumigating system etc.

-

Safety inspection device:

-

temperature/moisture inspection sensors for corn seed silos

-

Silo Materials:

-

Hot-dip galvanized steel sheet

-

Certification:

-

ISO BV CE for seed silos bins

-

Galvanized coating:

-

275g/m2

Grain storage grain silos (also called grain storage bins) are the efficient and economical facilities to handle your grains, which offer protection from outside insects and other affects as well as provide handling management conveniently.

All of our steel grain silos can be designed and installed with heat retaining layer to meet your special insulated grain storage demands.

Our innovative, high-quality flat bottom grain silos, hopper bottom grain silos, powder grain silos, feed grain silos, bucket elevators, dust collectors and grain storage control system are integrated as a system to satisfy your grain storage requirements.

Description of Power Silos

Powder silos (Powder bins) are widely used to hold and discharge flour and other powder materials such as cement and PFA (Pulverized Fuel Ash). Powder is not easy to store and deliver. Steel powder storage silo is your good choice to hold and discharge weighty powder materials. Flour is such kind of powder as the basic ingredient for many food products and stored in silos up to 20 meters high. The filling and emptying of powder silo is often performed by pneumatic systems that transport the stored powder from the large external powder bins and deposit them in smaller holding vessels for further processing. The filling and emptying processes are controlled by reliable level measurement. Pressure monitoring is also required in the pneumatic conveying pipelines. Elevators or conveyors can also be used to handling powder transporting.Powder steel silo is your good choice to hold and discharge weighty powder materials. Powder storage silos have the characteristics of lower cost, shorter construction time and unloading materials easily. The capacity of Shelley steel powder storage silos ranges from 20m³ to 800m³.

Features of Powder Silos

· Perfect sealing assures its efficient working performance.

· convenient installation.

· Waterproof and moisture-proof.

· Screw connection on inner side, anti-corrosion.

· Can be customized.

· Safe and reliable.

· Unhindered discharge, no blocking.

Components of Powder Silos

Powder silo (powder bin) includes the silo roof, silo body and silo hopper with legs. Powder silo roof, body, hopper are made of carbon steel, with food grade painting, make sure the safety of the flour; On silo roof, there are flour inlets, safety valve, Vibration filter, Explosion-proof vent, manhole. On silo body, there are ladder, ladder safety guard, level indicator. Powder silo leg is made of round pipe or H beam steel (with normal painting), based on the silo size. According to the customer’s requirement, Powder silo also can be made with stainless steel.

Powder silo can be used indoor or outdoor, round type or square type, no normal specifications. Shelley Engineering can design the flour silo to satisfy the your requirements.

Insulated Powder Silos

Powder or flour product is not easy to store or handle, it should be batch stored in ventilated, cool and dry place, to avoid direct sunlight, prohibited contact with the items that may react, and pay attention to moisture. So the thermal insulated bins are widely used for powder storage. Powder silos can be designed and installed with heat retaining layer to meet your special insulated powder storage requirements. The insulated flour bins are widely used in places where the temperature is large difference between the day and night and humid sites like seaside, they are also widely used in places where the weather are very cold at all seasons which can influence the quality of stored feed pellets. Steel insulated bins will keep the stored powder products in controlled condition. The capacities of our assembly hopper bottom bins can cover the capacities from 10 tons to 10000 tons.

Applications of Powder Silos

Powder silos are widely used in flour mill, flour plant, wheat maize farm, food processing plants or feed production lines, etc. They are also can store cement, powder, lime, gypsum, fly ash, different binder materials, gravel, limestone, sand and different chippers.

Square silos for grain storage introduction ;

50ton feed silo,200ton corn storage grain silo roof , made of galvanizing sheet .

Pecification for your reference as follows.

Steel Grain Square Silos Silo Roof

Assembly flour storage silo tank body

The flour storage silo tank is made of high quality hot-dip galvanizing steel sheet corrugated by special equipments, used grain storage silos body sheets are connected by high yeild bolts, the thickness of silo sheet is designed according to the constant strength theory. There are stiffeners fixed on the body ,which is used to bear the vertical friction force and support the silo body;The bolts and nuts are fixed with spherical waterproof washers. There are Aviation special waterproof rubber strip between the small grain storage silos sheets. The flour storage silo tank is equipped with round door, inside and outside ladder.

Grain storage silo bottom

steel storage silo from 5tons to 50tons,hopper and legs are made of galvanizing steel.

For the steel hopper angle, we usully use 60degree steel hopper angle,because

60 degree easy to flow out the material from the silo.

For the feed,it doesn't has good fuludity

We can give you the drawing designs for free as follows

|

Ton |

Model |

Diameter (m) |

Height (m) |

Weight (ton) |

Volume (m³) |

|

300 |

TCZK06410 |

6.4 |

17 |

12 |

411 |

|

500 |

TCZK08210 |

8.2 |

18 |

17 |

710 |

|

1000 |

TCZK10014 |

10 |

24 |

32 |

1449 |

|

3000 |

TCZK15518 |

15.5 |

24 |

44 |

4088 |

|

5000 |

TCZK18323 |

18.3 |

30 |

77 |

7187 |

|

10000 |

TCZK27518 |

27.5 |

28 |

150 |

14000 |

| For more product information , please click | CONTACT US > |

We also provide relevant supporting products

Accessory Equipments:

- Bucket Elevator with capacity from 1 tone/hour to 400 tone/hour - Chain Conveyor with capacity from 1 tone/hour to 400 tone/hour - Screw Conveyor with capacity from 1 tone/hour to 200 tone/hour - Elevator Towers - Electrical and Manuel controlled Slide gates - Distributors with 1 in 2/3/4/5/6 out - Catwalks - Spout Pipes

Machines:

- Drying Machines ( Tower Type and Horizontal Type ) with capacity from 5 tone/hour to 50 tone/hour

- Mill Machines with capacity from 5 tone/hour to 50 tone/hour

- Pellet Machines with capacity from 5 tone/hour to 50 tone/hour

-Level sensors, aeration system with centrifugal fan, temperature control system and sweep auger, dedusting system as an option.

Installation can be carried out in different ways

*If the client wants to install 10ton-1500ton steel hopper bottom grain silos by themselves, we could offer detailed instruction, and we'll give our quickest response to deal with any question in the process.

*We could also send our engineer to supervise the installation process. The client could find local workers for the installation work and our engineer will help them during the process.

*If the client needs, we could send our installation team for the whole installation issue.

FAQ

Q 1 : What certifications do you have?

A1: ISO certification , BV certification and CE certification .

Q2: What is the export customs code of your product?

A2: 7309000000

Q3. What is your payment method?

A3: 30% advance payment for foreign projects, full delivery.

Q4.Can you do custom design and production?

A4: The selection of prefabricated steel 10ton-1500ton steel hopper bottom grain silos is fixed, and the diameter cannot be changed. If other 10ton-1500ton steel hopper bottom grain silos such as flour 10ton-1500ton steel hopper bottom grain silos, cement 10ton-1500ton steel hopper bottom grain silos, and square 10ton-1500ton steel hopper bottom grain silos are required, they can be customized for production.

Q 5. About installation, how to install? How much is the installation fee?

A5: Abroad: Generally 1-2 people guide the installation, each person 100 dollars per day.

Q6: What materials are used for your steel warehouse?

A6: At the top of the warehouse, the barrel is a galvanized steel sheet, the cone bottom with a diameter of 4.5m is galvanized sheet, and the cone bottom with a diameter of 4.5 to 11m is a carbon steel sheet.

Q7: What are the types of steel 10ton-1500ton steel hopper bottom grain silos in your company?

A7: We mainly have cone bottom steel 10ton-1500ton steel hopper bottom grain silos, flat bottom steel 10ton-1500ton steel hopper bottom grain silos, cement 10ton-1500ton steel hopper bottom grain silos and flour 10ton-1500ton steel hopper bottom grain silos.

Q8: Can you provide supporting equipment? What can be provided?

A8: Yes. Cleaning equipment includes cleaning screen, vibrating screen, dust removal equipment, and conveying equipment including hoist, scraper, belt conveyor, and screw conveyor.