- Product Details

- {{item.text}}

Quick Details

-

Processing width:

-

300-1000mm

-

Grinding heads:

-

16

-

Grinding head diameter:

-

200

-

Grinding width:

-

10-40mm

-

ITEM:

-

67

-

Function:

-

Floor Grinidng Polishing

Quick Details

-

Place of Origin:

-

China

-

Weight:

-

5000 kg

-

product name:

-

Easy To Operating Automatic Grinding Polishing Machine

-

Processing width:

-

300-1000mm

-

Grinding heads:

-

16

-

Grinding head diameter:

-

200

-

Grinding width:

-

10-40mm

-

ITEM:

-

67

-

Function:

-

Floor Grinidng Polishing

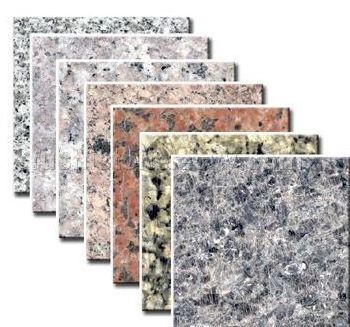

terrazzo floor tile making machine

Grinding Polishing Machine

Main function and characteristic

Multihead stone polishing machine machine with 9-12-16-18 heads, this machine is mainly for slab polishing. the struture is reasonable, steady performance, high work effiency. With the import PLC controlling systerm, text display is controlled intelligence.

1.Out airbag, long life using, lower hazard rate, lower maintenance cost, etc advantage.

2. With the best quality belt with famous brand, thickness accord, promise the thickness of the slab.

3. Belt move and bridge move is controlled with the automatic controlling system

4. With lower power (7.5kw single head), lower cost, Capacity is 38 square meter per hour. The brightness for G3786 can catch up 85 degree.

5.The control system of this machine adopts PLC terminal control with LCD touch screen terminal for parameter setting and faulte prompts during operationm etc. It is applicable to continuours grounding and polishing granite tile. Operating speeds of plate coverying and crossbeam of polishing disc are controlled by frequency converter. working pleasure and the polishing width of tile are adjustable within the setting values. This machine can also automatically identify the shape of tile, so that each polishing disc (polishing head) could automatically lift and lower according to the identified shape of tile, and conduct tracking records for tile polishing at the same time. The overall machine is produced according the standard requirements with performance up to the leading domestic level.

6. All the electrical parts adopt famous brand, the PLC is Siemens and other electrical parts mainly are Schneider, so these can ensure the machine’s stability and long-term working.

Technical data

|

Processing width |

Max 900mm,1300mm |

|

Processing thickness |

Max30mm |

|

Grinding Heads |

9/12/16 |

|

Capacity: |

300-500 square meter per 8hours |

|

Grinding head power |

9/12/16/18x7.5kw |

|

Belt move power |

1.5kw |

|

Bridge move power |

3kw |

|

Belt move speed |

600-2200mm/min |

|

Pressure: |

0.6-0.8Mpa |

|

Cooling water pressure |

in 0.15Mpa |

|

Consumption water for single grinding |

25L/min |

|

Machine size |

7500*2200*2100mm/9600*2200*2100mm,/10800*2200*2100mm |

Feature

1). Is PLC controlled - Is simple to operate and maintain; and it is with the function of Data input and output, Logic control and fault, and Self-diagnostic ,etc.

2). Requires just a few hours of instruction to become familiar with its operation;

3). Occupies and needs very little floor area for production;

4). May be disconnected from the power supply and ‘stored’ when not in use;

5). Designed and constructed to the same high-quality engineering standards for which all of our equipment is known.

6). Imported hydraulic components are adopted in hydraulic system, the pressure can be adjusted. And Precise control components action.

7). Take use "program-controlled" Transmission positioning, stable transmission, accurate setting;

8). Take vibration on worktable ,rotating multi - layer cloth, high frequency pressure, automatic propulsion, etc. make molding cycle is short, high production efficiency, quality and density of large tiles, high strength, dimensional accuracy.

9). This machine works in many ways. By changing molds, it could produce roof tile, stair tile...