- Product Details

- {{item.text}}

Quick Details

-

Insulation Material:

-

none

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DLX

-

Model Number:

-

Cr20Ni80

-

Product name:

-

nichrome Cr20Ni80 Ni80 wire

-

Surface:

-

Bright

-

Process method:

-

Drawing And Rolling

-

Treatment:

-

Hydrogen Annealing

-

Condition:

-

Soft Annealed

-

Ribbon size:

-

0.05*0.2-2.0*6.0mm

-

Melting point:

-

1400℃

-

Certificate:

-

ISO,ROHS

-

MOQ:

-

1pcs

-

Delivery time:

-

3-15 days

Quick Details

-

Application:

-

Heating

-

Conductor Material:

-

Nickel,chrome

-

Conductor Type:

-

Solid

-

Insulation Material:

-

none

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DLX

-

Model Number:

-

Cr20Ni80

-

Product name:

-

nichrome Cr20Ni80 Ni80 wire

-

Surface:

-

Bright

-

Process method:

-

Drawing And Rolling

-

Treatment:

-

Hydrogen Annealing

-

Condition:

-

Soft Annealed

-

Ribbon size:

-

0.05*0.2-2.0*6.0mm

-

Melting point:

-

1400℃

-

Certificate:

-

ISO,ROHS

-

MOQ:

-

1pcs

-

Delivery time:

-

3-15 days

Nichrome wire

Nichrome alloy includes pure nickel, NiCr alloy, Fe-Cr-Al alloy and copper nickel alloy.

Nickel chrome alloys: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni90Cr10, Ni30Cr20, pure nickel Ni200 and Ni201

FeCrAl alloy: 0Cr25Al5, 0Cr23Al5, 0Cr21Al4, 0Cr27Al7Mo2, 0Cr21Al6Nb, 0Cr21Al6.

Copper nickel alloy: CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi23, CuNi30, CuNi44, Constantan,CuMn12Ni

Our Nichrome alloy are in the form of wire, coil, ribbon, strip, foil

Nichrome wire sizes are:

Wire: 0.018mm-10mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

Bar: 10-100mm

Nichrome 80 20

Nichrome Grade: Ni70Cr30,Ni80Cr20, Ni60Cr15, Ni35Cr20, Ni30Cr20

NiCr 80/20 also called Chromel A, Cr20Ni80, N8, Nichrome V, HAI - NiCr 80, Tophet A, Resistohm 80, Cronix 80, Protoloy, Alloy A,

MWS-650, Stablohm 650, NCHW1

nicr8020 characteristic

Chemical Content %: 80.00 Nickel, 20.00 Chrome

Max continuous service temperature: 1200ºC

Resisivity: 1.09 mm2Ω /m

Density: 8.4g/cm3

Thermal conductivity: 60.3kj/mhc

Coefficient of thermal expansion: 18*10-6/c

Melting point: 1400ºC

Elongation: Min 20%

Austenite

Nonmagnetic

Nickel chrome alloys: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni90Cr10, Ni30Cr20, pure nickel Ni200 and Ni201

FeCrAl alloy: 0Cr25Al5, 0Cr23Al5, 0Cr21Al4, 0Cr27Al7Mo2, 0Cr21Al6Nb, 0Cr21Al6.

Copper nickel alloy: CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi23, CuNi30, CuNi44, Constantan,CuMn12Ni

Our Nichrome alloy are in the form of wire, coil, ribbon, strip, foil

Nichrome wire sizes are:

Wire: 0.018mm-10mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

Bar: 10-100mm

Nichrome 80 20

Nichrome Grade: Ni70Cr30,Ni80Cr20, Ni60Cr15, Ni35Cr20, Ni30Cr20

NiCr 80/20 also called Chromel A, Cr20Ni80, N8, Nichrome V, HAI - NiCr 80, Tophet A, Resistohm 80, Cronix 80, Protoloy, Alloy A,

MWS-650, Stablohm 650, NCHW1

nicr8020 characteristic

Chemical Content %: 80.00 Nickel, 20.00 Chrome

Max continuous service temperature: 1200ºC

Resisivity: 1.09 mm2Ω /m

Density: 8.4g/cm3

Thermal conductivity: 60.3kj/mhc

Coefficient of thermal expansion: 18*10-6/c

Melting point: 1400ºC

Elongation: Min 20%

Austenite

Nonmagnetic

|

Alloy Nomenclature Performance

|

|

Ni80Cr20

|

Ni70Cr30

|

Ni60Cr15

|

Ni35Cr20

|

Ni30Cr20

|

|

|

Main Chemical composition

|

Ni

|

Rest

|

Rest

|

55.0-61.0

|

34.0-37.0

|

30.0-34.0

|

|

|

|

Cr

|

20.0-23.0

|

28.0-31.0

|

15.0-18.0

|

18.0-21.0

|

18.0-21.0

|

|

|

|

Fe

|

≤1.0

|

≤1.0

|

Rest

|

Rest

|

Rest

|

|

|

Max. continuous service temp. of element(ºC)

|

|

1200

|

1250

|

1150

|

1100

|

1100

|

|

|

Resistivity at 20ºC (μΩ·m)

|

|

1.09

|

1.18

|

1.12

|

1.0

|

1.04

|

|

|

Density(g/cm3)

|

|

8.40

|

8.10

|

8.20

|

7.90

|

7.90

|

|

|

Thermal conductivity (KJ/m·h·ºC)

|

|

60.3

|

45.2

|

45.2

|

43.8

|

43.8

|

|

|

Coefficient of lines expansion(α×10-6/ºC)

|

|

18.0

|

17.0

|

17.0

|

19.0

|

19.0

|

|

|

Melting point approx.( ºC)

|

|

1400

|

1380

|

1390

|

1390

|

1390

|

|

|

Elongation at rupture(%)

|

|

>20

|

>20

|

>20

|

>20

|

>20

|

|

|

Micrographic structure

|

|

austenite

|

austenite

|

austenite

|

austenite

|

austenite

|

|

|

Magnetic properties

|

|

nonmagnetic

|

nonmagnetic

|

Weak magnetic

|

Weak magnetic

|

Weak magnetic

|

|

The application areas of nickel-chromium alloy strips include:

Petrochemical industry: used to manufacture pipes, valves, pumps and other components in petrochemical equipment, as well as catalyst carriers for petrochemicals.

Aerospace industry:

used to manufacture high-temperature components such as engines, turbine blades, and combustion chambers.

Chemical industry:

used to manufacture reaction kettles, heat exchangers and other components in chemical equipment.

Devices:

used to manufacture devices such as artificial joints and dental implants.

Other fields: such as nuclear industry, electronics industry, etc.

CHANGZHOU DLX ALLOY CO, LTD

was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate

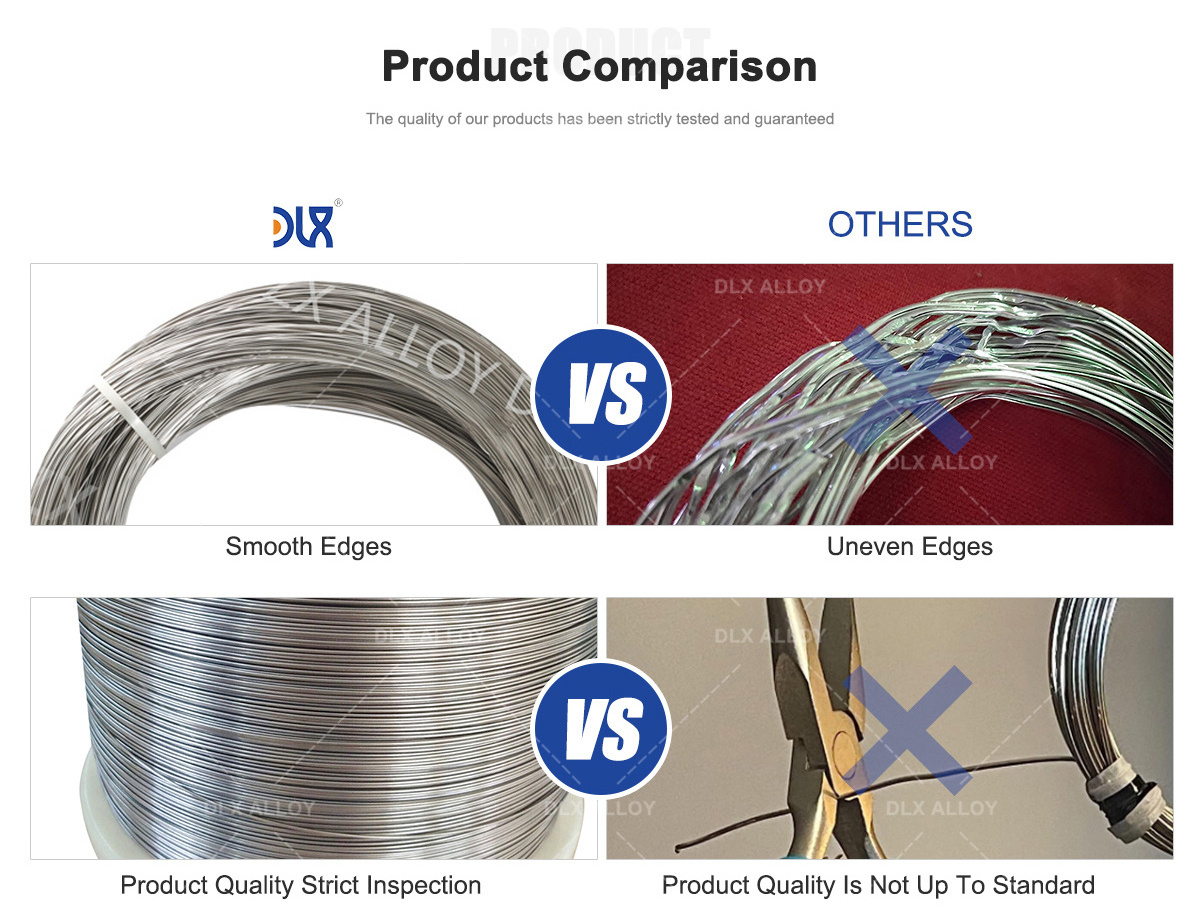

Our Advantage

1.Market Leader

Top 5 in China's nonferrous metal industry

2.Flexible products

Thousands of product specifications,Meet multiple needs of buyers

3.Low MOQ

Can customize samples

4.Short production lead time,fast delivery of whole cabinet

5.Professional inspection equipment

Before delivery, we will use spectrometers, tensile testers and other professional equipment to conduct a comprehensive inspection of the products to ensure that the goods are qualified for acceptance

6.Professional business team

Quickly responds to customer inquiries,24-hour professional quotation online

The salesperson will follow the customer's requirements for the use of the product,Professionally recommend more appropriate performance and price products to customers

7.Intact packaging

Packaging according to customer needs.You can customize wooden boxes to ensure that the goods arrive at the destination in good condition

8.Various payment methods

Facilitate customer payment

9.Get good reviews from customers

Old customers have long-term cooperation,The longest is more than 7 years

10.Received various awards

Google is very recognized by us,They give us awards every year

NiCr 80:20 – Industrial furnaces (upto 1200°C), electric cooking equipment, precision resistors.

NiCr 70:30 – Industrial furnaces (upto 1230°C) with alternating oxidizing/reducing atmosphere, precision resistors.

NiCr 60:15 – Industrial furnaces (upto 1100°C), electrically heated equipment, high-resistance and potentiometer resistors.

NiCr 40:20 – Domestic heating appliances (upto 1050°C), furnaces in carburising or semi-reducing atmosphere.

NiCr 30:20/ NiCr 20:25 – Industrial furnaces (upto 1050°C), heating elements of cooking equipment.

NiCr 70:30 – Industrial furnaces (upto 1230°C) with alternating oxidizing/reducing atmosphere, precision resistors.

NiCr 60:15 – Industrial furnaces (upto 1100°C), electrically heated equipment, high-resistance and potentiometer resistors.

NiCr 40:20 – Domestic heating appliances (upto 1050°C), furnaces in carburising or semi-reducing atmosphere.

NiCr 30:20/ NiCr 20:25 – Industrial furnaces (upto 1050°C), heating elements of cooking equipment.

Customer first and Best price offer!

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

After sale service:

24 hours on alibaba for after sale service

Alibaba trade assurance

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

After sale service:

24 hours on alibaba for after sale service

Alibaba trade assurance

Packing&Shipping

Hot Searches