- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

350 mm

-

Max. Table Load(kg):

-

5000

-

Travel (W-axis) (mm):

-

9000 mm

-

Positioning Accuracy (X axis) mm:

-

9000

-

Positioning Accuracy (Y axis) mm:

-

0

-

Positioning Accuracy (Z axis) mm:

-

350

-

Range of Spindle Speed(r.p.m):

-

150 r.p.m

-

Spindle Motor Power(kW):

-

150

-

Production Capacity:

-

1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EAST AI

-

Voltage:

-

220V /380V

-

Dimension(L*W*H):

-

2570x1175x1920mm

-

Weight (T):

-

6 T

-

Name:

-

CNC honing machine for hydraulic cylinder pipe

-

Keyword:

-

Cnc Honing Machine For Hydraulic Cylinder Pipe

-

Color:

-

As required

Quick Details

-

Table Size (mm):

-

930x1130

-

Table Travel (X) (mm):

-

9000 mm

-

Table Travel (Y) (mm):

-

0 mm

-

Table Travel (Z) (mm):

-

350 mm

-

Max. Table Load(kg):

-

5000

-

Travel (W-axis) (mm):

-

9000 mm

-

Positioning Accuracy (X axis) mm:

-

9000

-

Positioning Accuracy (Y axis) mm:

-

0

-

Positioning Accuracy (Z axis) mm:

-

350

-

Range of Spindle Speed(r.p.m):

-

150 r.p.m

-

Spindle Motor Power(kW):

-

150

-

Production Capacity:

-

1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EAST AI

-

Voltage:

-

220V /380V

-

Dimension(L*W*H):

-

2570x1175x1920mm

-

Weight (T):

-

6 T

-

Name:

-

CNC honing machine for hydraulic cylinder pipe

-

Keyword:

-

Cnc Honing Machine For Hydraulic Cylinder Pipe

-

Color:

-

As required

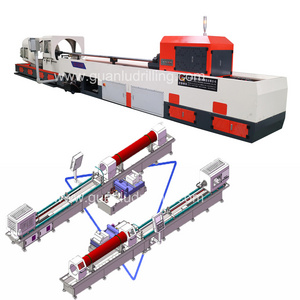

HM50X4000 Deep hole honing machine

technical specifications

HM50*4000 Model Honing Machine Specification

ll.Characteristic

The HM50*4000 deep hole honing machine can realize constant pressure honingand easy of operation. The machine tool uses the workpiece to be fixed, and the honinghead rotates and reciprocates to finish honing process.The machine tool is suitable forhoning and polishing of cylindrical deep-hole workpieces, such as various hydrauliccylinders, air cylinders and other precision pipe fittings. The hole accuracy can reachIT6~T7 or above, and the surface roughness can reach Ra 0.1 u m Local honing cancorrect the taper,ellipticity, and local aperture errors of the workpiece. For some colddrawn steel pipes, powerful honing can be done directly. The honing machine is anideal equipment with high precision and high efficiency. It adopt the PLC system that isprogrammable and safe and convenient handling ,lt has the ability of smooth steeringand convenient speed adjustment, easy learning and convenient operation for theoperator ; one person can control multiple machines , ensures theaccuracy of the aperture size and reduces labor intensity.

During the honing process, the machine can safely and stably control the size ofthe honing head to ensure the uniformity of the aperture size and improve the efficiencyof honing deep hole processing. The honing head adopts a servo motor and a planetaryreducer to drive the precision ball screw to expand. The structure has a stable tensionforce, and the honing torque can be steplessly adjusted as required, and the honing

efficiency is high. The honing force of the sand stone is stable to ensure the roundnessand cxlindricity of the workpiece.The honing rod adopts a universal joint structure atone end to better ensure the straightness and the stability of the machine tool duringhoning. The machining diameter range of this machine tool is 63-4500mm. Thismachine tool has the advantages of convenient operation, high production efficiency,and good economic benefits. It can not only meet the needs of large-scale production,but also apply to the needs of single-piece small-batch processing. lt is an idealequipment for deep hole finishing.

IV、Processing accuracy

Dimensional accuracy: IT7

roughness : Ra≤0.8(polishing Ra≤0.4)

Roundness :≤0.04

V、Machine tool components

1. Rod grinding box: the rod grinding box adopts a closed box, and the 15kw variablefrequency motor drives spindle to rotate through driving spindle box gear directly.withstepless, speed regulation,and the speed adjustable range is 5-200rpm /min.Thespindle bearing adopts ZWZ bearing, the front end adopts double row tapered rollerbearing and two-way thrust ball bearing, and the rear end adopts double row taperedroller bearing. The output torque of the spindle is large and the transmission is stable.

2.Carriage reciprocating system: The carriage is installed on the linear guide rail.Theservo motor drives the carriage to reciprocate through the reducer drive chain. Thereciprocating speed is 1-40m/min to meet the speed requirements of the processingaperture. The linear guide is equipped with an automatic lubrication device.

3. Cooling system: The cooling system adopts three-stage filtration ofsedimentation-magnetic drum-non-woven fabric. The filtration accuracy is less than10um. The internal oil inlet mechanism independently developed by our company cancool the honing head, clean the inner hole every moment, and the honing speed isfaster and the fineness is higher.

4. Workpiece. clamping: The workpiece. is positioned and clamped on the V-shapedblock fixed on the worktable through the chain.The carriage can move on the guide railto adapt to the work piece of different length. The honing machine designed by ourcompany is a manual clamping mechanism, which is more convenient for workers andhigh efficient.

5、Bed part: lIt consists of two parts: the workpiece bed and the carriage bed.lt adopts square steel frame type welded structure, steel pipe is heavy-dutymaterial, and the net width of the bed is 900mm. The bed has been temperedtwice to ensure the stability of the bed. HGH45 heavy linear guide rails areinstalled on the carriage bed, which has a higher service life and higheraccuracy. The linear guide has an automatic lubrication mechanism. Thesemi-protection of the machine tool is made of plastic-sprayed sheet metal,and there is organ protection in the sports bed to ensure that the guide rail isnot damaged in the harsh working environment .

6 、Electrical part: The machine adopts Wuxi Xinie PLC control system duringthe honing process,which can realize automatic cycle control; movementspeed,workpiece, length,working time and working cycle times can becontrolled at will , convenient and fast, and completely humanized control, thusensuring Hole processing accuracy and size consistency and reduce laborintensity and labor costs. At the same time, it can also monitor the runningstatus of the machine tool and give real-time alarms for system failures thatoccur, so that it is convenient and quick to detect problems and handle failures.

7、Cooling pump motor alarm

There are fault indication and fault text display. The fault point can be quickly judged

through the fault indication and text display

Common fault information:

1. The spindle inverter alarms 2. The feed servo motor alarms.

3.Limit alarm 4.Emergency stop alarm

5.Servo drive failure alarm 6. Spindle cooling fan alarm

VI、Machine tool components list

|

No.

|

Item

|

unit

|

QTY

|

Remark

|

|

1

|

bed

|

suit

|

1

|

|

|

2

|

Honing rod box

|

suit

|

1

|

|

|

3

|

Supporter of honing rod

|

suit

|

1

|

|

|

4

|

Carriage feeding system

|

suit

|

1

|

|

|

5

|

Cooling paper tape magnetic drum filtration system

|

suit

|

1

|

|

|

6

|

Clamping device

|

suit

|

1

|

|

|

7

|

Electric control system

|

suit

|

1

|

|

|

8

|

cabinet

|

suit

|

1

|

|

VII、Main purchased parts list

|

No

|

Item

|

model

|

QTY

|

maker

|

original

|

|

1

|

Spindle bearing

|

|

1 suit

|

HRB,ZWZ,LYC

|

Domestic famous

|

|

2

|

Main motor

|

15kW inverte

|

1 suit

|

zhiyuan

|

Beijing

|

|

3

|

inverter

|

|

1 suit

|

Yiqu

|

shenzhen

|

|

4

|

Reciprocating motor

|

28NM servo

|

1 suit

|

Xinjie

|

Wuxi

|

|

5

|

Tension motor

|

3.2NM servo

|

1 suit

|

Xinjie

|

Wuxi

|

|

6

|

Servo driven

|

|

2 suit

|

Xinjie

|

Wuxi

|

|

7

|

Low voltage electrical elements

|

|

1 suit

|

CHINT

|

Shenzhen

|

|

8

|

Linear rail

|

|

1 suit

|

Taiyin

|

Taiwan

|

|

9

|

Control system

|

PLC

|

1 suit

|

Xinjie

|

Wuxi

|

|

10

|

cable

|

|

1 suit

|

Domestic famous

|

|

VII、Attached technology files

Application

◆ Our History

Founded in 2006, specialized in producing honed tube and chrome rod used for hydraulic and pneumatic cylinder. We also produce customized hydraulic cylinder as per drawing.

◆ Our Factory

Located in Luqu Industry Park, Wuxi city

Located in Luqu Industry Park, Wuxi city

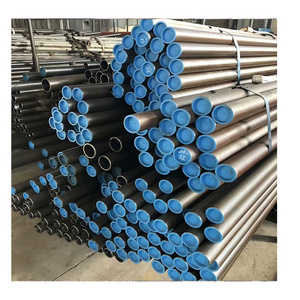

◆ Our Product

Honed tube, skived roller burnished tube, chrome plated rod, hollow piston rod, chrome plated honed pipe, hydraulic cylinder, hydraulic power unit. Pneumatic cylinder tube.

Honed tube, skived roller burnished tube, chrome plated rod, hollow piston rod, chrome plated honed pipe, hydraulic cylinder, hydraulic power unit. Pneumatic cylinder tube.

◆ Product Application

Excavator, Forklift, All kinds hydraulic cylinders and pneumatic cylinders.

Excavator, Forklift, All kinds hydraulic cylinders and pneumatic cylinders.

◆ Our Certificate

ISO9001:2008, CE

ISO9001:2008, CE

◆ Production Equipment

CNC, Honing machine, cold drawn machine, skiving roller burnishing machine, grinding machine, polishing machine, automatic straightening machine, heat treatment furnace, etc.

CNC, Honing machine, cold drawn machine, skiving roller burnishing machine, grinding machine, polishing machine, automatic straightening machine, heat treatment furnace, etc.

◆ Production Market

Vietnam, Thailand, Indonesia, India, Brazil, Peru, Columbia, Argentina, Russia, UK, USA, South Africa, etc

Vietnam, Thailand, Indonesia, India, Brazil, Peru, Columbia, Argentina, Russia, UK, USA, South Africa, etc

◆ Our Service

Machining service, Third party inspection service

Machining service, Third party inspection service

Our Services

East Ai has a powerful team which has inddependent design development of pneumatic components from product design to peoduction operations

In case the product does not meet your expectations, we offering a sampling service ,giving you the opportunity to properly evaluate products before you buy.

In order to meet higher requirements from customers around the world ,we import premiere machines from developed countries

Packing & Shipping

Packing Details :Inner brown craft paper/outside carton/wooden pallets.

Delivery Details : 20-25 days after received the payment.

Delivery Details : 20-25 days after received the payment.

FAQ

Q1: Are You Manufacture or Trade Company?

A1: We are manufacture,we have 10 years experience for supply Metal material and products in domestic.

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: What is your terms of payment ?

A3:

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: What is your terms of payment ?

A3:

1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.Upon negotiation

Q4: Can you provide Certificates for aluminum materials ?

A4:Yes,we can supply MTC-Material Test Certificate.

Q5: Can you provide sample?

A5: Yes, we can provide you sample, but you need to pay for the sample and freight firstly. We will return the sample fee after you make an order.

2.30% down payment, the balance 70% paid against L/C at sight

3.Upon negotiation

Q4: Can you provide Certificates for aluminum materials ?

A4:Yes,we can supply MTC-Material Test Certificate.

Q5: Can you provide sample?

A5: Yes, we can provide you sample, but you need to pay for the sample and freight firstly. We will return the sample fee after you make an order.

Hot Searches