- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ODMT

-

Model Number:

-

MPTA05-400

-

HS Code:

-

8414809090

-

Material:

-

Aluminum Alloy and Stainlesss Steel

-

standard or nonstandard:

-

customization

-

keyword:

-

pressure testing machine

-

Application:

-

Burst Test for Pipes/Valves/Hoses

-

Boost Medium:

-

water/hydraulic oil

-

OEM:

-

available

-

Maximum Output Pressure:

-

<=600 Mpa

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Shandong, China, Shandong China

-

Brand Name:

-

ODMT

-

Model Number:

-

MPTA05-400

-

HS Code:

-

8414809090

-

Material:

-

Aluminum Alloy and Stainlesss Steel

-

standard or nonstandard:

-

customization

-

keyword:

-

pressure testing machine

-

Application:

-

Burst Test for Pipes/Valves/Hoses

-

Boost Medium:

-

water/hydraulic oil

-

OEM:

-

available

-

Maximum Output Pressure:

-

<=600 Mpa

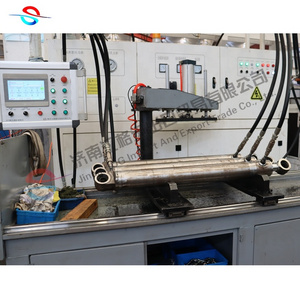

Product Description

The MLPS series pressure test bench is specially designed to conduct blasting and impulse withstand pressure tests on various hoses, hoses, metal pipes, joints, containers, etc., to assess their fatigue life and failure forms, and automatically identify and perform automatic identification of sample damage or machine failure. Deal with it accordingly and achieve automatic control.

The system uses a air driven liquid booster pump for pressure, and uses pneumatic servo intelligent control technology during the test. The test process and data collection are controlled by a computer.

Specification

|

item

|

value

|

|

Warranty

|

1 Year

|

|

Customized support

|

OEM

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

ODMT

|

|

Model Number

|

MLPS

|

|

Power

|

Hydraulic

|

|

Product name

|

Computer Control Hydraulic Pressure Test Bench

|

|

Function

|

pressure test

|

|

Keyword

|

Withstand pressure test bench

|

|

Material

|

Stainless Steel

|

|

Name

|

Pressure holding test bench

|

|

Color

|

Silver

|

|

Accuracy

|

0.5%

|

|

Brand

|

ODMT

|

|

Power supply

|

pneumatic

|

|

Certificate

|

CE ISO

|

Technical Parameter

|

Project requirements

|

Performance index

|

remarks

|

|

function

|

Pressure test/burst test

|

|

|

Test medium

|

Water/

|

Customer-provided

|

|

Maximum test pressure

|

16MPa

|

The range can be set.

|

|

Pressure test accuracy

|

±0.5%F.S

|

|

|

Pressure control accuracy

|

±2%F.S

|

|

|

medium temperature

|

room temperature

|

|

|

ambient temperature

|

room temperature

|

|

|

Number of simultaneous tests

|

1 piece

|

|

|

Control mode

|

Automatic control. PLC+ test software controls the whole system and detects the test process, and finally issues the test report.

|

Siemens PLC is adopted, which has the functions of dynamically displaying and automatically recording and saving test times,

pressure and test waveforms, and is convenient to query and print out. |

Feature of Machiry

(1) carry out pressure explosion test on various hoses, hoses, metal pipes, joints, containers;

(2) The gas-driven liquid booster pump is adopted as the booster equipment, which is controlled by proportional servo, with fast boosting speed and stable pressure;

(3) All valves, pipe fittings and joints used are made of stainless steel;

(4) American NI software is adopted, which has the functions of dynamic display and automatic recording and saving of test times, pressure and test waveforms, which is convenient for query and printout;

(5) When the requirements are met, automatically stop the test and complete the task alarm buzzer;

(6) Stop working automatically when a sample is broken, and give an alarm;

(7) The test bench is equipped with a panic button, and the test can be stopped immediately in case of any accident.

(8) Typical test procedures are:

Constant speed boosting-pressure maintaining-blasting

Constant speed boosting-pressure maintaining-pressure releasing

Constant speed boosting-pressure maintaining-constant speed boosting-pressure maintaining-until blasting

Test Bench Structure

|

Main components

|

Detailed composition

|

Function description

|

|

Power system

|

Air compressor (provided by the user), two-piece body, solenoid valve...

|

Provide power for the test bench pressurization system

|

|

Test cabinet

|

The frame structure is welded by ordinary Stainless Steel profiles

|

The test box has explosion-proof function as a whole, and the size is designed according to customer requirements

|

|

Booster system

|

It consists of gas-liquid booster pump, two-piece, etc.

|

Convert the computer control signal and the power source of the test bench into the withstand pressure

|

|

Control System

|

It consists of proportional valve, solenoid valve, high-pressure air-controlled needle valve, etc.

|

Control the boost rate through a proportional valve.

|

|

Liquid-filled exhaust system

|

It consists of water injection pump, filter and solenoid valve.

|

After the test piece is filled with water, close the solenoid valve of the injection pump

|

|

Test piece installation room

|

It consists of liquid filling system, exhaust system, explosion-proof box, etc.

|

Single station design, the state of the test piece can be observed through the observation window during the test

|

|

electrical control system

|

Equipped with electrical control panel

|

|

|

measuring system

|

Pressure sensor, pressure gauge, etc.

|

Data measurement for pressure

|

|

Control System

|

Computer, control board, measurement and control software

|

|

Hot Searches