- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V,50Hz/220V,50Hz,or customized

-

Power:

-

40kw

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

22500x1200x2200mm

-

Capacity:

-

120-1200kg/h

-

Raw materials:

-

meat meal, fish meal,corn powder, soya meal and other grains powder

-

Flow chart:

-

Mixing---Extrusion----drying---Flavoring

-

dryer fuel:

-

electric,gas,diesel,LPG

-

Motor:

-

Siemens

-

Electric part:

-

Fuji, LG, Siemens,Scheider,Mitsubish

-

Main motor power:

-

30/37/55/75/110KW

-

Machines Materials:

-

stainless steel

-

Model:

-

LT65/70/85/90 FT75/95

-

Product name:

-

dog food machine

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Arrow

-

Voltage:

-

380V,50Hz/220V,50Hz,or customized

-

Power:

-

40kw

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

22500x1200x2200mm

-

Capacity:

-

120-1200kg/h

-

Raw materials:

-

meat meal, fish meal,corn powder, soya meal and other grains powder

-

Flow chart:

-

Mixing---Extrusion----drying---Flavoring

-

dryer fuel:

-

electric,gas,diesel,LPG

-

Motor:

-

Siemens

-

Electric part:

-

Fuji, LG, Siemens,Scheider,Mitsubish

-

Main motor power:

-

30/37/55/75/110KW

-

Machines Materials:

-

stainless steel

-

Model:

-

LT65/70/85/90 FT75/95

-

Product name:

-

dog food machine

Product Description

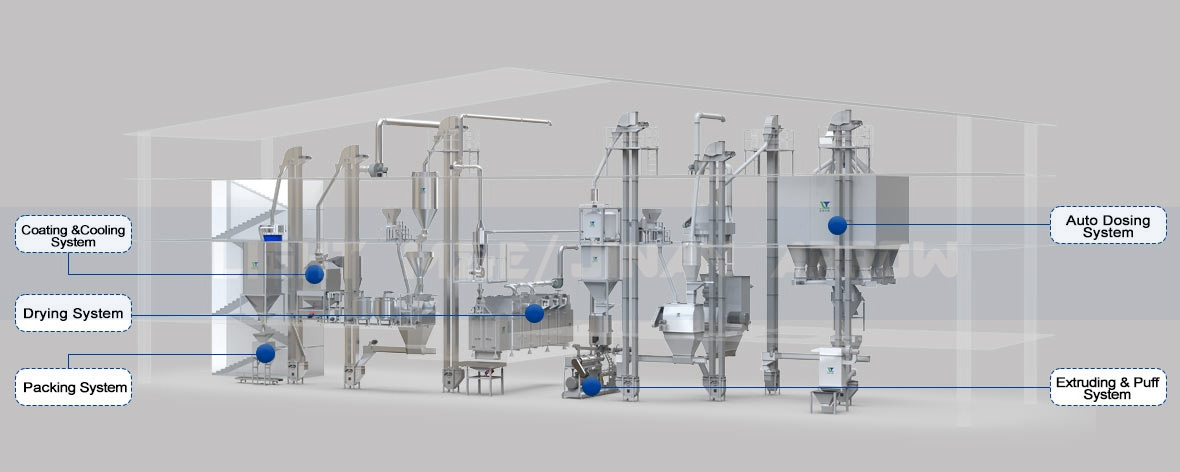

High Quality And High Efficiency Pet Food Extruder Pellet Dog Food Machine

With the increasing variety of pet, people require more and more different pet food. In order to meet various feeding demands,Our company developed the pet food machine line,easy operation, friendly human-machine interface, accurate control to ensure the pet food can be processed under stable temperature, pressure, humidity and other circumstance.

Raw Material:

Meat meal, Bone powder, Corn powder, Soya meal and other grains' powder

Work Flow

:

Mixing→Extruding→Drying→Flavoring→Cooling→Packaging

Main Features

As 30+ years Experienced Professional Manufacturer of Food Extrusion Machinery, we provide Turn-key Solution for you, including whole process flow design, building layout design and building construction guide.

✍ WHOLE PROCESS FLOW DESIGN

We have our own experienced production working flows, we can also design the workingflow according to your demands.

✍ BUILDING LAYOUT DESIGN

✍ BUILDING LAYOUT DESIGN

Our engineers will prepare the whole line layout drawing according to your workshop, if workshop is not uniform, we can also design the layout according to its shape and size.

✍ BUILDING CONSTRUCTION GUIDE

✍ BUILDING CONSTRUCTION GUIDE

Our engineers will guide you how to design and prepare the workshop building.

✍ APPLICATION

✍ APPLICATION

Pet Food, Dog Food, Cat Food, Bird Food,etc.

sample show

By changing the extruder molds and formula, Pet Food Machine Line can produce the innovative shapes,high nutritional and savory taste pet food for dog, cat, fox, bird etc.

Flow chart

|

Name

|

Raw materials receiving, pre-cleaning and storage system

|

|

Process

|

Unloading, pre-cleaning, dust collector, bucket elevator, weighing, rotary distributor, chute, silo, etc

|

|

Usage

|

Different raw materials in-feed, such as packaging bags, ton bags, truck bulk materials, etc

|

|

Customized Solutions

|

Provided

|

|

Name

|

Mixing System

|

|

Application

|

used for the mixing of powder, granular, flake, lump and other material

|

|

Materials

|

3 material options: carbon steel; stainless steel; composite

|

|

Features

|

Fast speed, high uniformity, fast discharge, low material residue rate and environmental protection

|

|

Name

|

Grinding System

|

|

Cleaning and Maintenance

|

Big access door and hammer lock for quick cleaning and maintenance

|

|

Application

|

Materials

|

|

Feature

|

Domestic/imported Siemens motor optional, with imported high-quality bearing.

|

|

Name

|

Extrusion System

|

|

Materials

|

Pre-conditioner : stainless steel

Screw and screw Segments : special aloy material

PLC centralized control : Siemens and other international brands

|

|

Usage

|

AYT series twin extruders equipped with two co-rotating screws that release a quantity of mechanical energy suitable to reach the gelatinisation levels necessary to process any raw material and product . In addition , the barrel is conditioned to give further energy to the extrusion of the materials

|

|

Name

|

Drying System

|

|

Circulating

Flow Design

|

Turns most of the humid air into high -

temperature dry air after removing moisture , reducing heat waste |

|

Stainless Steel

Slat Belt

|

Using stainless steel strips with

baffles on both sides to limit the material to a reasonable area |

|

Dryer Door

Insulation

Layer

|

High temperature resistant

polyurethane foam with low thermal conductivity |

|

Name

|

Coating System

|

|

Usage

|

Fully contact with food surface , and the spraying is uniform

|

|

The Adding Quantity

|

controled by computer , measurement is more accurate

|

|

Mode

|

Drum Coating and Vacuum coating optional according to technique requirement .

|

|

Name

|

Cooling system

|

|

Principle of Use

|

Counter flow cooling principle

|

|

Feature

|

▶Application of air lock, big air intake area, cooling effect is significant;

▶Swing discharge mechanism, no residual;

▶Low energy consumption and easy operation; ▶After cooling, finished products temperature not higher than the room temperature +3℃~5℃ |

|

Name

|

Packing System

|

|

Summary

|

A complete set of solutions including automatic weighing, sealing, marking and coding, packing, palletizing, etc.

|

|

Packaging Forms

|

bag filling and packing machines,

semi-automatic packing

|

Related Products

Packing & Delivery

Packing method: plastic film packaging, external wooden or container

Shipping method: sea or express

Hot Searches