Extrusion blow molding process consists of 5 steps:

1. The plasticized raw materials are made into plastic embryos;

2. Cut off part of the type embryo and cut off the type embryo by closing the mold;

3. Fill gas into the mold cavity to mold the embryo, and cool it;

4. Open the mold and take out the molded container;

5. Trim the flying edge to get the finished product.

- Product Details

- {{item.text}}

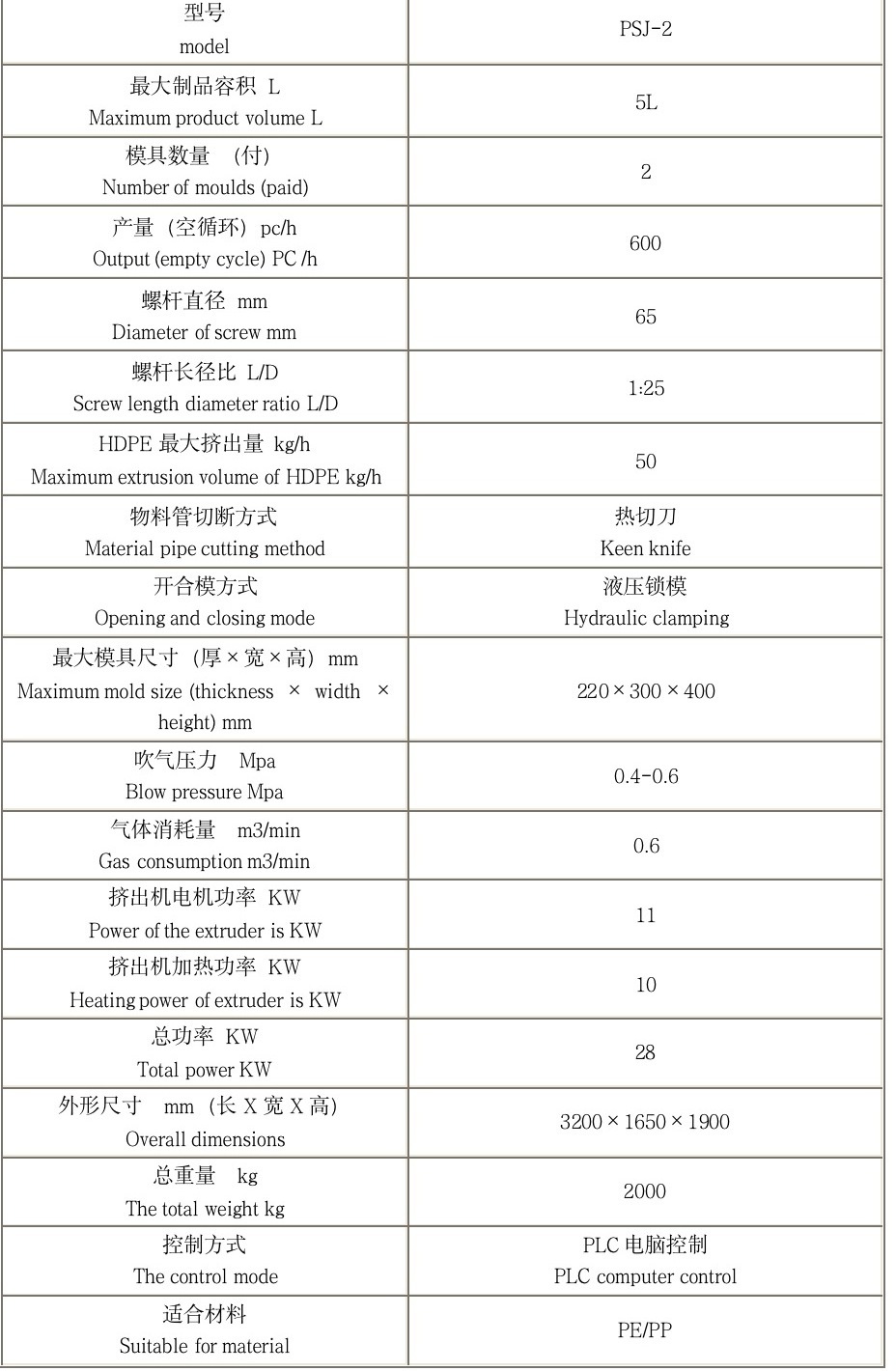

Quick Details

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

2900*1800*1800

-

Hollow part volume:

-

5L

-

Screw L/D Ratio:

-

26

-

Screw diameter (mm):

-

65 mm

-

Screw Heating Power(kW):

-

10 kW

-

Extruder Motor Power(kW):

-

10 kW

-

Mold Platen Size(Width)(mm):

-

300 mm

-

Mold Platen Size(Height)(mm):

-

400 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.6 m³/min

-

Die Head Heating Power(kW):

-

10 kW

-

Accumulator Capacity(L):

-

100 L

-

Power (kW):

-

30

-

Weight (T):

-

2

-

Material:

-

PP PE HDPE

-

Local Service Location:

-

no

-

MACHINE SIZE:

-

3000*1750*2100mm

-

Machine:

-

Blow Molding Equipment

-

Packing:

-

Wooden Box

-

Delivery Time:

-

30~40 Working Days

-

Certification:

-

CE Certificated

-

More application:

-

Popsicle

-

Processing Type:

-

Extruding Machine

-

Advantage:

-

Simple Operation

Quick Details

-

Clamping Force (kN):

-

1500

-

Output (kg/h):

-

150 kg/h

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

2900*1800*1800

-

Hollow part volume:

-

5L

-

Screw L/D Ratio:

-

26

-

Screw diameter (mm):

-

65 mm

-

Screw Heating Power(kW):

-

10 kW

-

Extruder Motor Power(kW):

-

10 kW

-

Mold Platen Size(Width)(mm):

-

300 mm

-

Mold Platen Size(Height)(mm):

-

400 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.6 m³/min

-

Die Head Heating Power(kW):

-

10 kW

-

Accumulator Capacity(L):

-

100 L

-

Power (kW):

-

30

-

Weight (T):

-

2

-

Material:

-

PP PE HDPE

-

Local Service Location:

-

no

-

MACHINE SIZE:

-

3000*1750*2100mm

-

Machine:

-

Blow Molding Equipment

-

Packing:

-

Wooden Box

-

Delivery Time:

-

30~40 Working Days

-

Certification:

-

CE Certificated

-

More application:

-

Popsicle

-

Processing Type:

-

Extruding Machine

-

Advantage:

-

Simple Operation

Product Overview

Products Description

BOTTLE BLOWING MACHINE

Bottle blowing machine is a machine that blows bottles. The simplest explanation is a machine that can blow plastic particles (softened into liquid) or finished bottle embryos into bottles by certain technological means.

PRODUCT SPECIFICATIONS

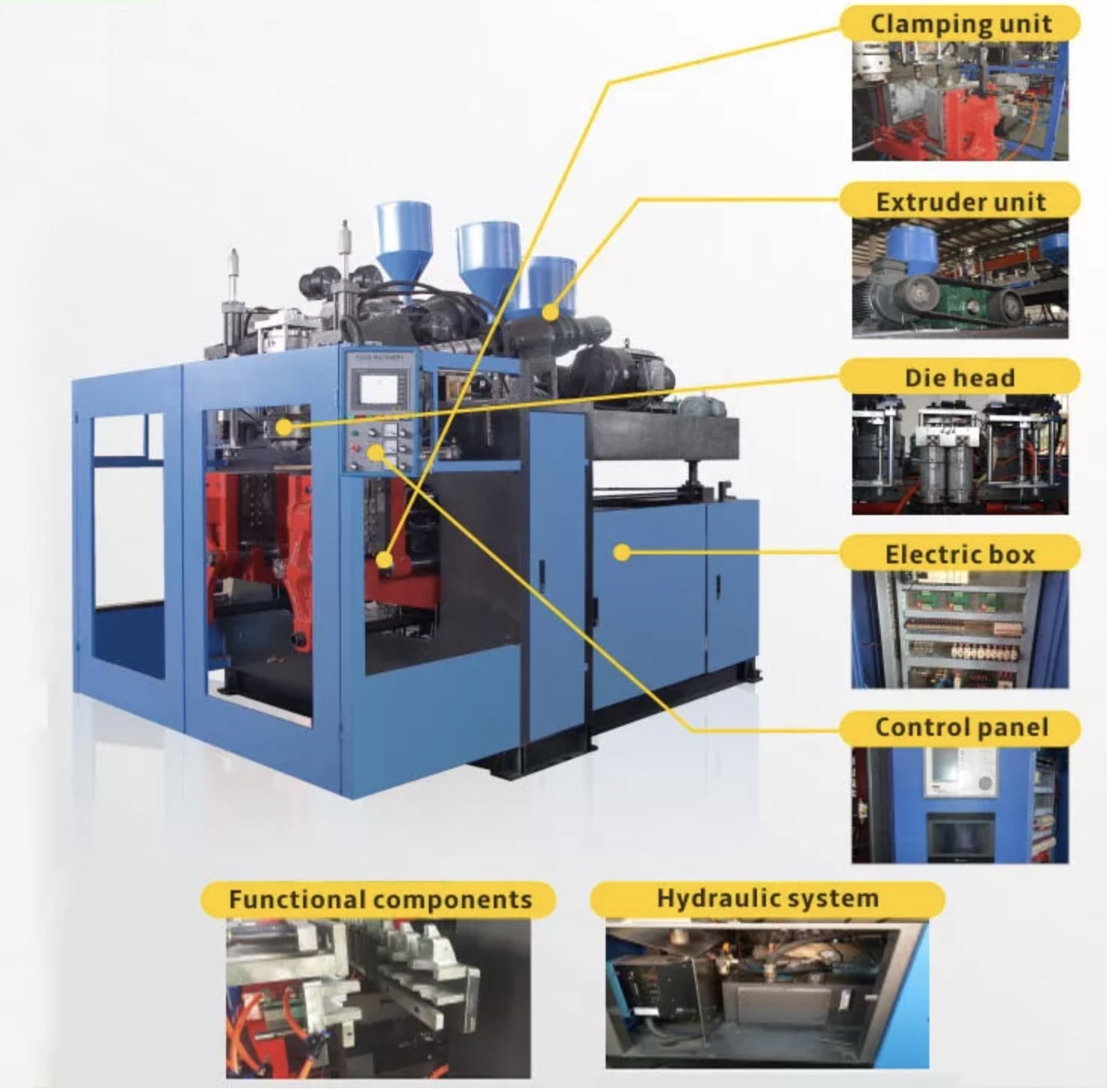

*PLC+touch screen: making the operation easy. Automatic malfunction alarm with self-diagnosis,making the malfunction clear at a glance.

*Unique “liner guide”: Unique “liner guide” to the clamping structure to ensure mold-lock uniform, knit line smoother.

*Process optional: the machine can be customized according to your price or requirements, such as pneumatic or hydraulic. Whether the machine wants to install a wall thickness controller. Have more choice in price.*Variety of functions for products: Variety of functions for different products matching the technological requirements: bottom blow and lift, rotation, encapsulation, material support, sub-mould, robot, parison control system, etc.

*Company strength: with a factory for more than ten years, we have professional experience and guarantee in experience and technology.

Applications

PRODUCT CONFIGURATION

BOTTLE MACHINE

MACHINE SHELL

PLC CONTROL

SALES AND SERVICE NETWORK

FAQ

Q1:*****

A1:*****

Packing and transportation

The export of the machine is protected by special export wooden cases to prevent damage in the sea

Hot Searches