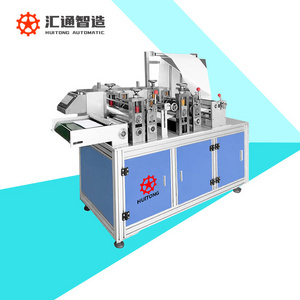

Founded in 1994, start with making PE foam net machine and fruit grading machine, during twenty five years of development, now has developed CE certified PS foam food container production line, Robot Arm Vacuum Forming Machine, EPE foam equipment, Fruits Cleaning, Waxing & Grading Machine, PE Cap Liner Foam Sheet Extrusion Line, PE/PS Recycling machine, totally more than 20 kinds of machines.

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fushi

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

12m*3m*1.8m

-

Power (kW):

-

28

-

Weight:

-

2 KG

-

Automatic Grade:

-

Automatic

-

Power:

-

28kw

-

Raw material:

-

LDPE

-

Final product:

-

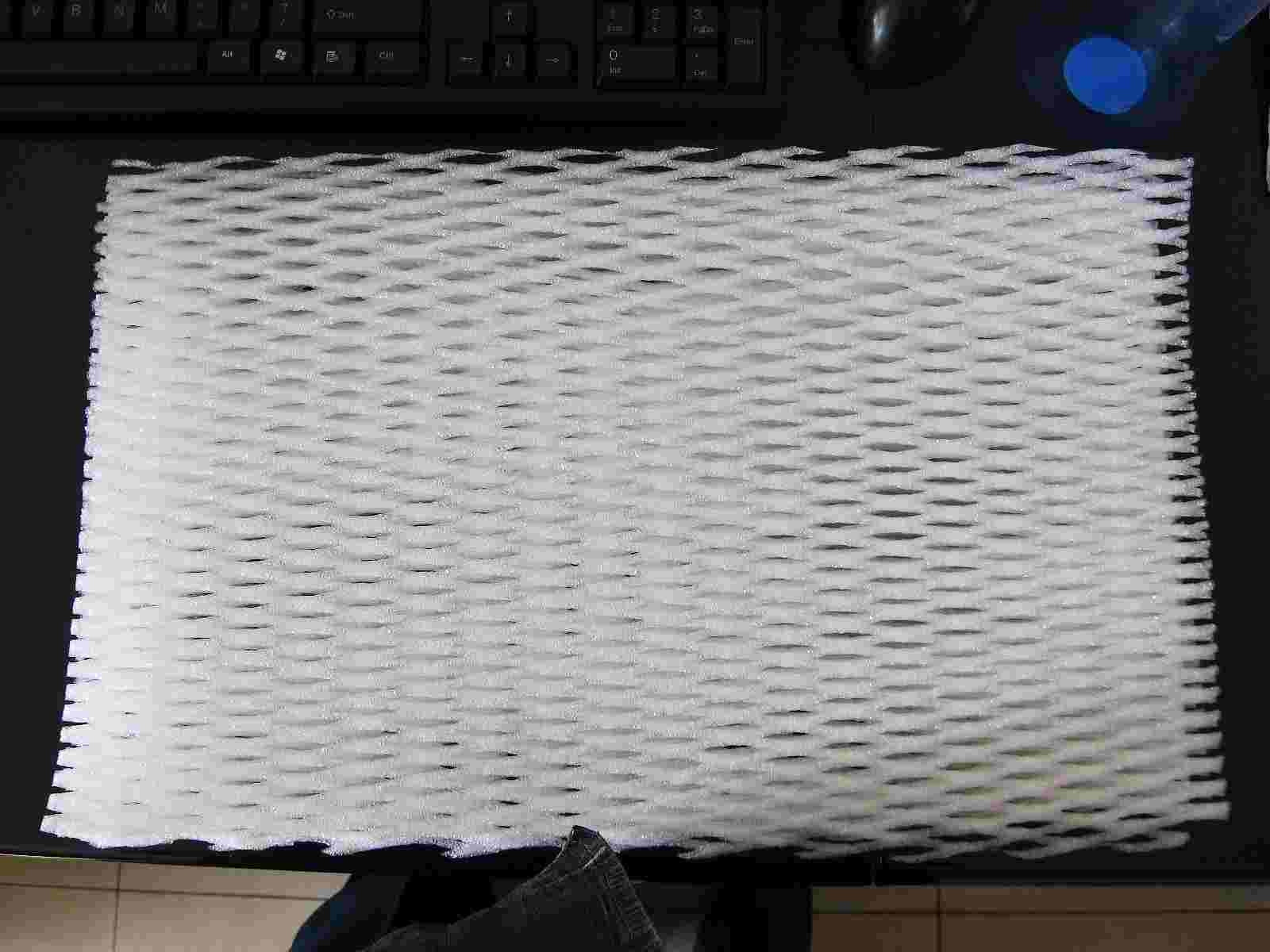

Foam net/pad

-

Leading time:

-

30 working days

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Online support

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

55:1

-

Screw diameter (mm):

-

75 mm

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fushi

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

12m*3m*1.8m

-

Power (kW):

-

28

-

Weight:

-

2 KG

-

Automatic Grade:

-

Automatic

-

Power:

-

28kw

-

Raw material:

-

LDPE

-

Final product:

-

Foam net/pad

-

Leading time:

-

30 working days

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Online support

-

Marketing Type:

-

Hot Product 2022

Product Application

1. This PE foam fruit net extrusion machine can produce PE foam net, which is new soft packing material.

2. Due to its unique expanding reticulation structure and the elastic foamed net film, it is widely used in the package of glass product, precision instrument, and various fruits.

|

SPECIFICATIONS

|

|

|

|

|||

|

|

Model

|

|

FS-FPW75

|

|||

|

|

Extruder

|

mm

|

75

|

|||

|

|

Screw Speed

|

r/min

|

5-50

|

|||

|

Main performance parameters

|

Foaming Rate

|

|

20-40

|

|||

|

|

Screw L/D

|

|

55:1

|

|||

|

|

Cooling Method

|

|

wind or water

|

|||

|

|

Installed Capacity

|

KW

|

28

|

|||

|

|

Dimension

|

(L*W*H)MM

|

12000*3000*1800

|

|||

|

|

Total Weight

|

T

|

3

|

|||

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Running in a high automatization and intellectualization,no pollution

|

Screw diameter

|

φ75mm

|

|

Screw L/D

|

55:1

|

|

Screw material

|

38CrMoALA

|

|

Barrel outside diameter

|

φ140mm

|

|

Drive type

|

Frequency converter motor

|

|

Heating type

|

temperature control meter

|

|

Mould

|

2pcs, customized.

|

|

Heating type

|

Stainless steel heating ring

|

|

|

|

|

Cooling type

|

Wind cooling

|

|

Die

|

High-speed rotating die, power: 3kw, frequency control timing

|

|

|

|

|

Cutter

|

|

|

|

Driving power

|

0.75KW

|

|

|

|

|

|

|

Speed regulation

|

Frequency Control Timing

|

|

|

|

|

|

|

|

|

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Q1. Is Longkou Fushi Packing Machinery a Manufacturer?

A1: We are a real factory in Yantai. China's outstanding machinery manufacturer

Q2: If we don't find what we need from your website, What should we do? Do you make a machine as per customers' specific requirement?

A2: Yes, we can provide bespoke service to customers with specific requirements. You can send detailed requirements by email. We will check if we can develop them. We develop new machinery every month, and some of them may not yet be updated on our website.

Q3: How can I order and make payments?

A3: Once clear your requirements and determined machine is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

Q4: How long is the delivery date?

A4: Usually it takes about 1 - 4 months depends on different machinery upon receipt of order advance payment.

Q5: What is your Minimum Order Quantity?

A5: One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

Q6: What about shipping?

A6: We can send the small spare parts by air express for an urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Qingdao port, which is convenient for maritime transportation.

Q7: Is there any pre- after sale service?

A7: Yes, we support our business partners by pre-after sale service. We provide training, testing, operation, and maintenance service for a lifetime.

Q8: Where is your factory located? How can I visit there?

A8: Our factory is located in Longkou city, Shandong province, you can fly to Yantai Penglai International Airport. When you confirm the flight No. and time, please tell me then we will pick you up at the Airport.