JS twin-shaft concrete mixer can be chose according to client;

Discharging height is 1.7-3.8(m);

Pneumatic/Hydraulic Control;

Easy replacing of wearing parts, such as liner plates.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

18.5-250kw

-

Dimension(L*W*H):

-

in detail

-

Weight:

-

25000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Concrete mixing plant

-

Type:

-

HZS25/35/50/60/75/90/120/150

-

Spare parts supplying:

-

Lifelong Provide

-

Capacity:

-

25-150m3/h

-

Discharging Height:

-

3800mm /3900mm

-

Max. aggregate size(mm):

-

100mm

-

Application:

-

buildings, roads, bridges, docks, airport,, etc

-

Control system:

-

Standard System

Quick Details

-

Machine Type:

-

Production line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Chunyue

-

Power:

-

18.5-250kw

-

Dimension(L*W*H):

-

in detail

-

Weight:

-

25000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Concrete mixing plant

-

Type:

-

HZS25/35/50/60/75/90/120/150

-

Spare parts supplying:

-

Lifelong Provide

-

Capacity:

-

25-150m3/h

-

Discharging Height:

-

3800mm /3900mm

-

Max. aggregate size(mm):

-

100mm

-

Application:

-

buildings, roads, bridges, docks, airport,, etc

-

Control system:

-

Standard System

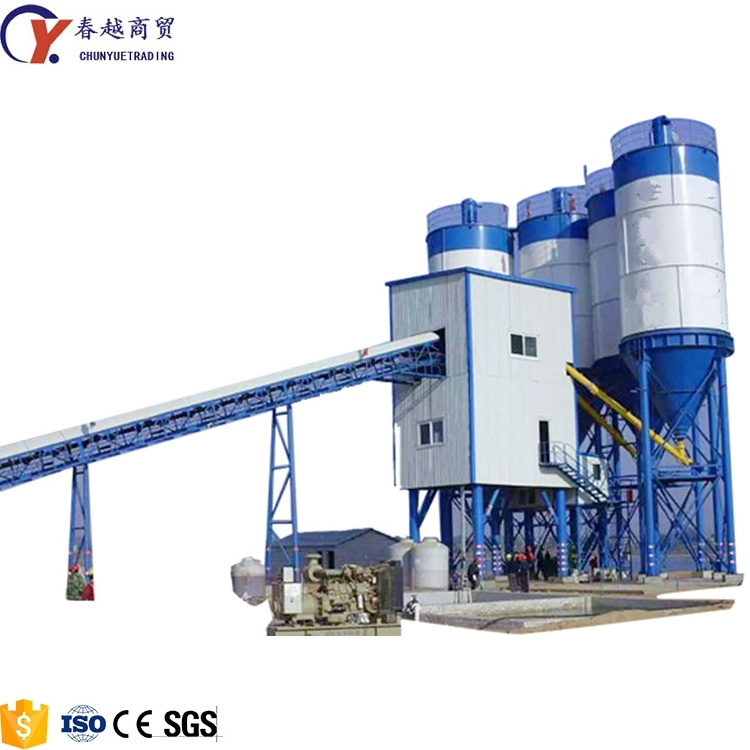

Factory price 60m3/h HZS60 belt conveyor concrete batching mixing plant for sale

Product of 60m3/h HZS60 belt conveyor concrete batching plant/concrete mixing plant price

HZS series concrete mixing plant belongs to compulsory and efficiency equipment. It includes JS concrete mixer, PLD batching machine,cement silo,conveying system and control system.And also has the characteristic of mixing well, high productivity, highly automated, high flexibility, convenient operation, and good stability.

Concrete mixing plant concrete mixing plant can be widely used in construction projects like buildings, roads, bridges, high way roads, docks, airport, water projects, hydropower station, etc. They can also be used in fibre reinforced concrete unit factories and used as commercial cyclone cement concrete mixing plant to sell high quality concrete to different buyers.

Main Features of60m3/h HZS60 belt conveyor concrete batching plant/concrete mixing plant price

1.Adopting horizontal twin-shaft compulsory mixer

2.The aggregate is measured accumulatively by electric scale

3.Water and additive is measured accurately under the control of the computer

4.The whole machine is controlled by computer which makes operation easy

5.The main electric components are from famous brand.

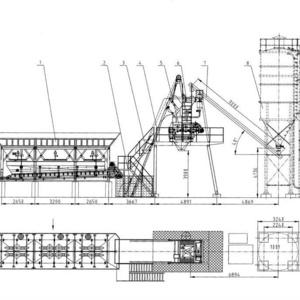

1. Mixing System

60m3/h HZS60 belt conveyor concrete batching plant/concrete mixing plant price

2. Cement system

60m3/h HZS60 belt conveyor concrete batching plant/concrete mixing plant price

Capacity of 50t, 100t, 150t and 200t are optional, with the cement smoke filter;

One-piece/Modular tank are optional.

3. Lifting System

60m3/h HZS60 belt conveyor concrete batching plant/concrete mixing plant price

Normally Lifting hopper be used in mixing plant less than 90m3/h, and belt conveying system be used in mixing plant

4. Control System

60m3/h HZS60 belt conveyor concrete batching plant/concrete mixing plant price

PLC/Centralized Control with the emergency stop button and safety control key;

TV monitoring systems for batching machine, concrete mixer and discharging mouth are optional for clients.

5. Aggregate System

60m3/h HZS60 belt conveyor concrete batching plant/concrete mixing plant price

2/3/4 hoppers with belt conveyor, pneumatic discharging mode with independent/ cumulative weighting.

|

Packaging of concrete batching plant/concrete mixing plant price

|

|

|

|

Size

|

depends on the models

|

|

|

Weight

|

depends on the models

|

|

|

Packaging Details

|

The normal package for standard parts is wooden box. If export to european countries, the wooden box will be fumigated. If container is too biger, we will use pe film for packing or pack it according to customers special request.

|

|

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of company, they are now strategically located home and abroad, working for our customers.

We are supply the spare parts for life time.

Your email address and telephone will not be shared or published!

Please fill in your need products and your message and do not forget mail and/or phone if you like to be contacted. we are the professional machine manufacturer in China.

I need to ask you some details for sending you the more suitable quotation,

1. What capacity do you want to get one day?

2. What control system do you need? Automatic, semi-automatic or Manual Control?

Of course, free live-chat is available and you can get help immediately. Or you can send me email .

You can get the price list and representative will contact you within one business day.

I hope you can tell me more details, i will give you the best quotation ASAP ,thanks. Your satisfaction is our greatest pursuit, we would like to sincerely for your service! We look forward to your inquiry!

Contact Information

Phoebe Wang

Pls contact us or send messages to us to get more details and discount, you will receive feedback within 12 hours!!!!