- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

7.1inch*2.5inch*1.2inch

-

Product name:

-

Abrasive silicon carbide sharpening stone sharpening deburring

-

Material:

-

Diamond, Zirconia

-

Size:

-

7.1inch*2.5inch*1.2inch

-

Shape:

-

cuboid

-

Color:

-

Green, blue, yellow, orange, purple, gray, can be customized

-

Grit:

-

Fine

-

Delivery time:

-

7-15 Days

-

Application:

-

Polishing

-

OEM:

-

OEM Welcomed

-

Package:

-

Carton Box

Quick Details

-

Type:

-

Sharpening Stones

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ENYING

-

Model Number:

-

7.1inch*2.5inch*1.2inch

-

Product name:

-

Abrasive silicon carbide sharpening stone sharpening deburring

-

Material:

-

Diamond, Zirconia

-

Size:

-

7.1inch*2.5inch*1.2inch

-

Shape:

-

cuboid

-

Color:

-

Green, blue, yellow, orange, purple, gray, can be customized

-

Grit:

-

Fine

-

Delivery time:

-

7-15 Days

-

Application:

-

Polishing

-

OEM:

-

OEM Welcomed

-

Package:

-

Carton Box

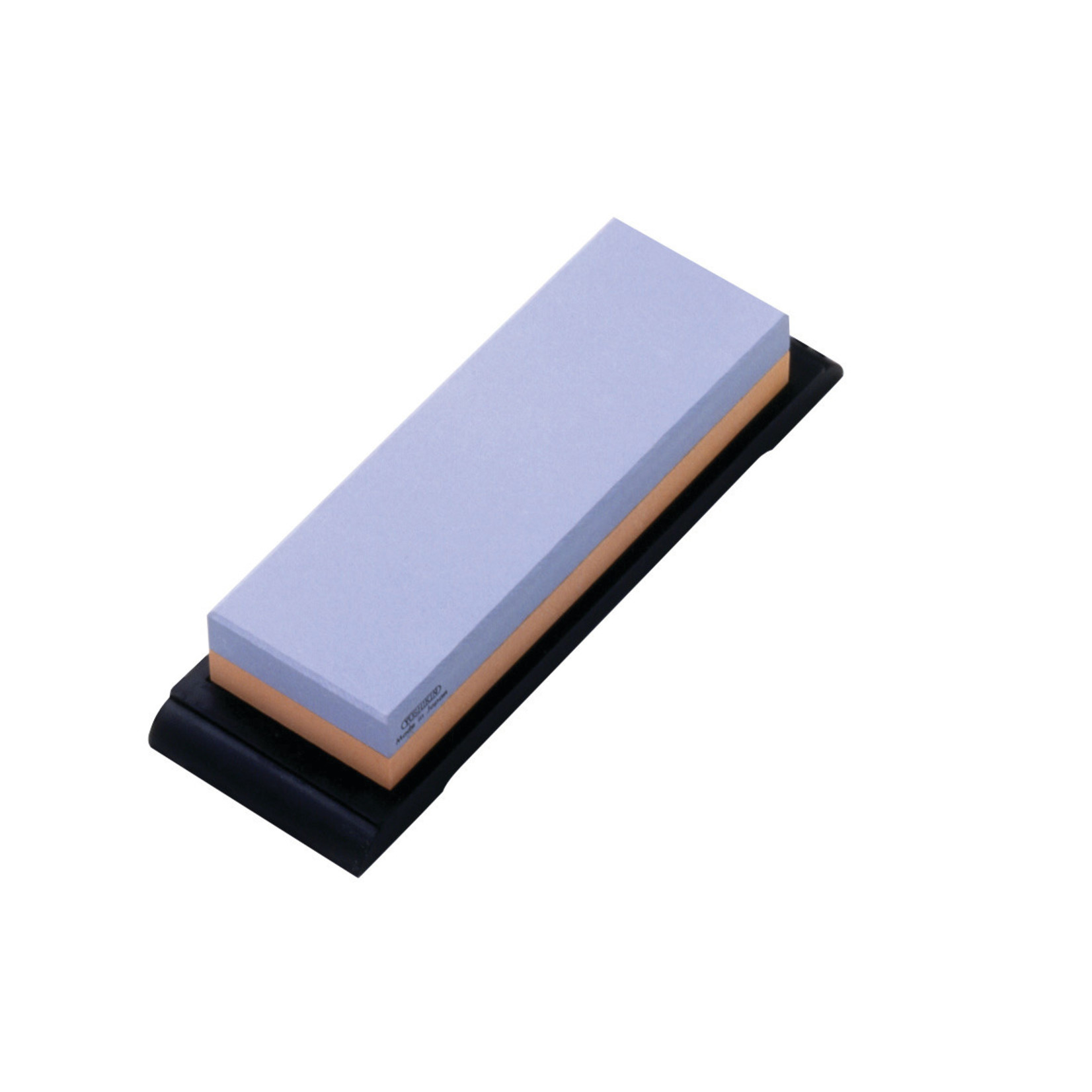

Abrasive silicon carbide sharpening stone sharpening deburring

A whetstone is a common grinding tool that is essential to keep your knives sharp and maintain their life. The whetstone can be used in home kitchens, industrial manufacturing, and outdoor camping.

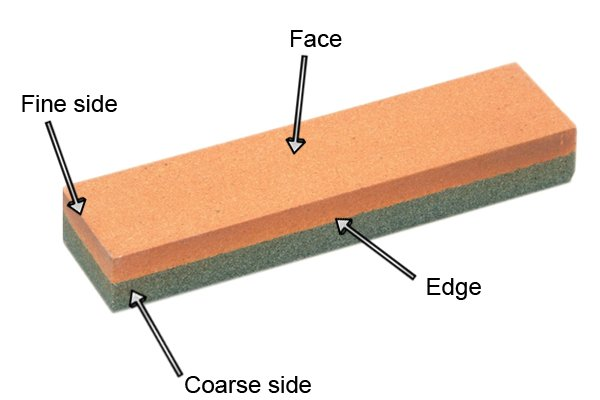

Generally speaking, a whetstone consists of an abrasive and a whetstone base. Abrasives usually use high hardness materials such as artificial silicon carbide, ceramic composite materials and diamonds, which have good grinding effect and wear resistance.

Compared with the traditional water grinding wheel, the whetstone is more flexible and convenient. The whetstone does not need to be soaked in water and will not wear down the knife. At the same time, the grinding effect of the whetstone is relatively uniform, and a more satisfactory sharpening effect can be obtained.

|

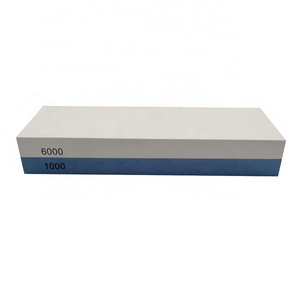

Size

|

180*60*27mm/203*76*27mm and customized is accepted

|

|

Grit number

|

1000/4000#,1000/6000#,3000/8000#,400/1000#,3000/6000, etc .

|

|

Color

|

Green/ Blue/ Red/ Yellow/ White and customized

|

|

Logo

|

OEM logo

|

High hardness is an important feature of whetstones.

The whetstone is made of hard stone, such as pyroxene, jadeite, ceramics, etc. These materials have very high hardness, which can make the whetstone have a good grinding effect. When we use a whetstone, we only need to follow the correct method to sharpen the sharp edge quickly and ensure the service life of the whetstone.

Good stability is another feature of the whetstone

The material and structure of the whetstone are very stable and can withstand various grinding pressures and angles. Even if it is used for a long time, the whetstone will not lose its original performance and effect. This makes the whetstone have good reliability and durability, which can meet people's needs for knife sharpening.

Application field 1

A whetstone can also be used to sharpen kitchen knives. The sharpness of knives directly affects our cooking efficiency in the kitchen. A sharp knife can quickly and accurately cut through a variety of ingredients, while a dull knife will make us struggle with poor results. Therefore, regular use of whetstones to sharpen knives can help us maintain the sharpness of kitchen knives, thereby improving our cooking efficiency in the kitchen.

Application field 2

Knife stones can also be used to sharpen mechanical tools such as lawnmowers and chainsaws. The sharpness of these tools is very important for their proper use and maintenance. If their sharpness is reduced, it will not only affect the use effect, but also increase the maintenance cost. Therefore, we must regularly use whetstones to sharpen lawn mowers and chain saws to keep them sharp and functioning properly.

Jinan Enying Machinery Manufacturing Co., Ltd. produces all kinds of standard abrasives. The company has more than 50employees(including more than 5 engineers and technicians), more than 30 sets of production equipment, and nearly $10,000 of fixedassets.The company mainly produces 100 - page wheel, cutting pieces, flocking pieces and other abrasive tools. Also according tothecustomer sample production processing. Products are exported to more than 100 countries and regions in South America,NorthAmerica, Europe, Southeast Asia, the Middle East, etc., trusted by customers with excellent quality. The company has nearlyten years of professional production history, rich experience, complete technical data, with a full set of production linescoveringhigh quality processing, assembly, inspection, packaging. The product quality fully conforms to national andinternationalstandards. The company strives for survival by quality and development by reputation, and constantly introducesadvancedtechnology and develops new products to better serve users. At the same time, the company warmly welcome domestic and foreigncustomers through technical cooperation and investment, common development.

Wynne zhang

+0086-15628888834

E-mail:liyue@zqhongdun.com

Hot Searches