- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5220*2760*5120mm

-

Power (kW):

-

20.7kw

-

Weight (KG):

-

8000 KG

-

Product Name:

-

EPS Shape Moulding Machine

-

Raw material:

-

expanded polystyrene(EPS)

-

Function:

-

4.moulding all the shape kinds of EPS products

-

Feature:

-

Full Automatic/running stable/energy saving

-

Advantage:

-

the latest design/high technology/high quality

-

Application area:

-

agriculture/fishery/packing field/building field

-

HS code:

-

84778000

-

After-sales Service Provided:

-

engineer field installation

-

Local Service Location:

-

vietnam/middle east/turkey

-

After Warranty Service:

-

Online support/engineer field installation

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Bes

-

Machine Type:

-

Typical and Economical

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5220*2760*5120mm

-

Power (kW):

-

20.7kw

-

Weight (KG):

-

8000 KG

-

Product Name:

-

EPS Shape Moulding Machine

-

Raw material:

-

expanded polystyrene(EPS)

-

Function:

-

4.moulding all the shape kinds of EPS products

-

Feature:

-

Full Automatic/running stable/energy saving

-

Advantage:

-

the latest design/high technology/high quality

-

Application area:

-

agriculture/fishery/packing field/building field

-

HS code:

-

84778000

-

After-sales Service Provided:

-

engineer field installation

-

Local Service Location:

-

vietnam/middle east/turkey

-

After Warranty Service:

-

Online support/engineer field installation

High Quality EPS Foam Styrofoam Shape Moulding Machine For Fish Box Cornice ICF Block Wash Machine Package Production Line

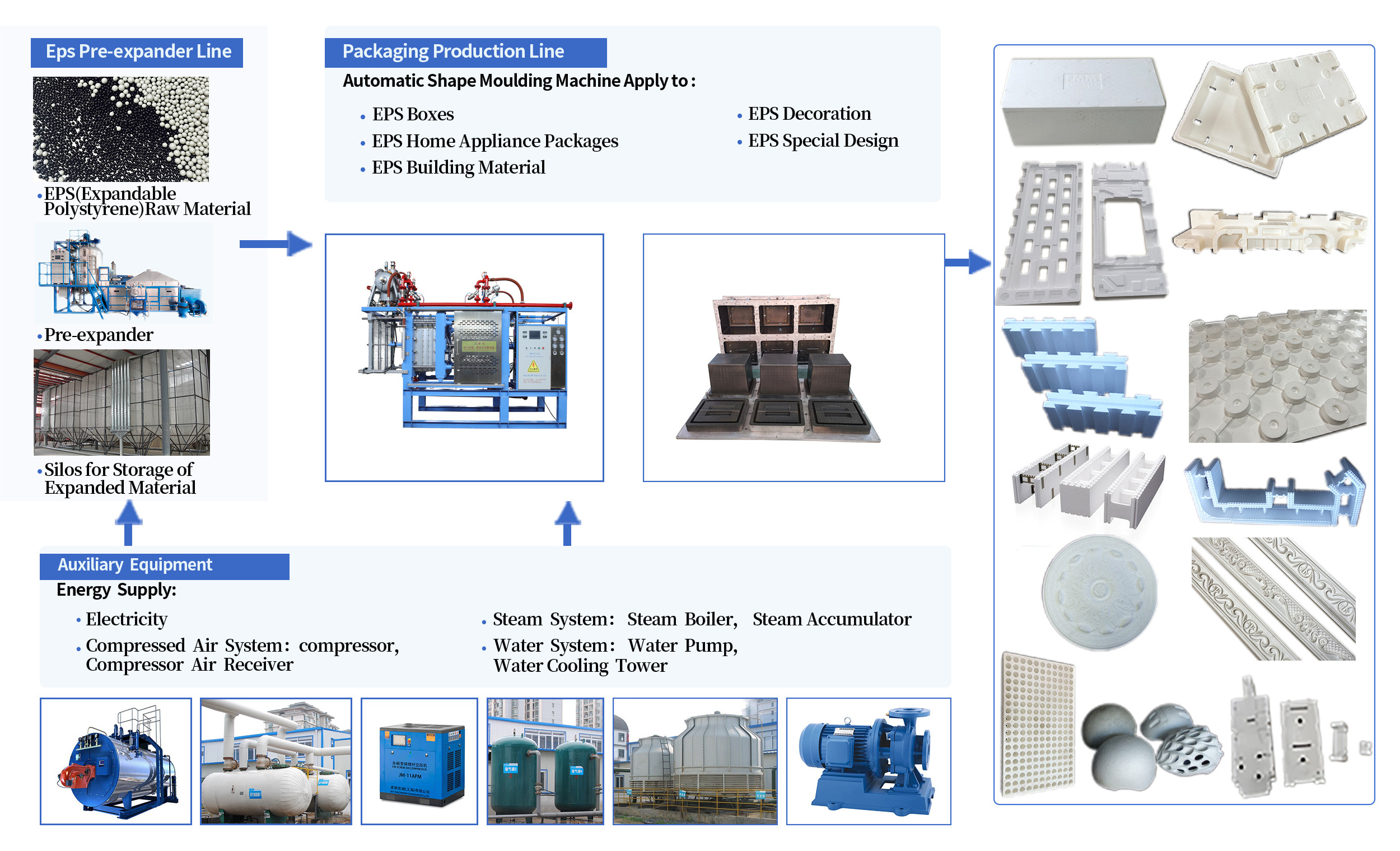

EPS Shape Moulding machine is defined as a process manufacturing EPS formed products such as EPS packages or insulation materials by the moulds are filled with expanded EPS beads by means of pneumatic filling injectors, pressure filling systems, shaped by steam heating in the closed state with the aid of a vacuum.

EPS foam products have wide application fields in heat insulation, food and electronics packaging and building decorates terms and so on.

EPS foam products have wide application fields in heat insulation, food and electronics packaging and building decorates terms and so on.

High Quality EPS Foam Styrofoam Shape Moulding Machine For Fish Box Cornice ICF Block Wash Machine Package Production Line

1. This machine applies PLC and touch screen,advanced moulding technique and can produce various

shapes of EPS products.

2. This machine can provide different kinds of foam articles with lower moisture content, high foaming speed and lower consumption of energy.

3. There are four kinds of operating mode (automatic,semi-automatic,pause-startup and manual operation)with safe-guard protective device to ensure safe operation.

4. This machine has microcomputer control and touch screen display. It can function high efficiently under computer control and management with high automation.Simplicity of operation and easy to maintain,it can reduce the labor intensity.

5. This machine applies advanced electrical and hydraulic integration system,which improves the moulding speed,lowers the energy consumption remarkably and reduces the environmental pollution.

6. Mechanic de-mould mode.

shapes of EPS products.

2. This machine can provide different kinds of foam articles with lower moisture content, high foaming speed and lower consumption of energy.

3. There are four kinds of operating mode (automatic,semi-automatic,pause-startup and manual operation)with safe-guard protective device to ensure safe operation.

4. This machine has microcomputer control and touch screen display. It can function high efficiently under computer control and management with high automation.Simplicity of operation and easy to maintain,it can reduce the labor intensity.

5. This machine applies advanced electrical and hydraulic integration system,which improves the moulding speed,lowers the energy consumption remarkably and reduces the environmental pollution.

6. Mechanic de-mould mode.

|

Technical Data

|

|

|

|

|

|

|||||

|

Item

|

Unit

|

BES-PZT-1400

|

BES-PZT-1600

|

BES-PZT-1750

|

BES-PZT-1800

|

|||||

|

Mould Dimension

|

mm

|

1400×1200

|

1600×1350

|

1750×1500

|

1800×1600

|

|||||

|

Max Product Dimension

|

mm

|

1200×1000×350

|

1400×1100×350

|

1550×1300×350

|

1610×1400×350

|

|||||

|

Rear Window Size

|

mm

|

1300×1080

|

1450×1150

|

1600×1350

|

1680×1440

|

|||||

|

Stroke

|

mm

|

270-1420

|

270-1420

|

270-1420

|

220-1370

|

|||||

|

Steam Entry

|

mm

|

DN100

|

DN100

|

DN100

|

DN100

|

|||||

|

Steam Consumption

|

t/t

|

(10-13T) steam consumption for 1T EPS raw material

|

|

|

|

|||||

|

Water Entry

|

mm

|

DN80

|

DN80

|

DN80

|

DN80

|

|||||

|

Cooling Water Consumption

|

kgs/cycle

|

50-150

|

55-180

|

60-190

|

80-200

|

|||||

|

Compressed Air Entry

|

mm

|

DN65

|

DN65

|

DN65

|

DN65

|

|||||

|

Compressed Air Consumption

|

m3/cycle

|

1.8

|

2

|

2

|

2.2

|

|||||

|

Vacuum Pump Capacity

|

m3/h

|

230

|

280

|

280

|

280

|

|||||

|

Connected Load

|

kw

|

15.2

|

17.2

|

17.2

|

20.7

|

|||||

|

Overall Dimension

|

mm

|

4920×2250×4660

|

5220×2680×4690

|

5220×2680×4790

|

5220×2760×5120

|

|||||

|

Machine Weight

|

kg

|

5700

|

7000

|

7500

|

8000

|

|||||

|

Cycle Time

|

s

|

60-150

|

90-160

|

90-160

|

120-190

|

|||||

|

Other Specifications Can Also Be Produced According to Client's Requirements

|

|

|

|

|

|

|||||

The Production Line

Hot Searches