- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

1

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

STANOK

-

Year:

-

Custom production

-

Power (kW):

-

35

-

Weight (KG):

-

8000

-

Marketing Type:

-

Customize product types

-

Name:

-

Hot Elbow Forming Machine

-

Industry of use:

-

Factories producing industrial pipe fittings

-

Finished pipe diameter:

-

21mm~1420mm

-

Machined pipe thickness:

-

3-120mm

-

Machining pipe bending Angle:

-

45°,90°,180° and random angle user demands

-

Elbow bending radius range:

-

1D~2.5D

-

place of origin:

-

Hebei,China

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Installation service:

-

Video guide installation, on-site installation

Quick Details

-

Machine Type:

-

Hot Elbow Forming Machine

-

Bending Radius (mm):

-

21 - 1420

-

Max. Bending Angle (Deg):

-

180

-

Bending Precision (Deg):

-

1

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

STANOK

-

Year:

-

Custom production

-

Power (kW):

-

35

-

Weight (KG):

-

8000

-

Marketing Type:

-

Customize product types

-

Name:

-

Hot Elbow Forming Machine

-

Industry of use:

-

Factories producing industrial pipe fittings

-

Finished pipe diameter:

-

21mm~1420mm

-

Machined pipe thickness:

-

3-120mm

-

Machining pipe bending Angle:

-

45°,90°,180° and random angle user demands

-

Elbow bending radius range:

-

1D~2.5D

-

place of origin:

-

Hebei,China

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Installation service:

-

Video guide installation, on-site installation

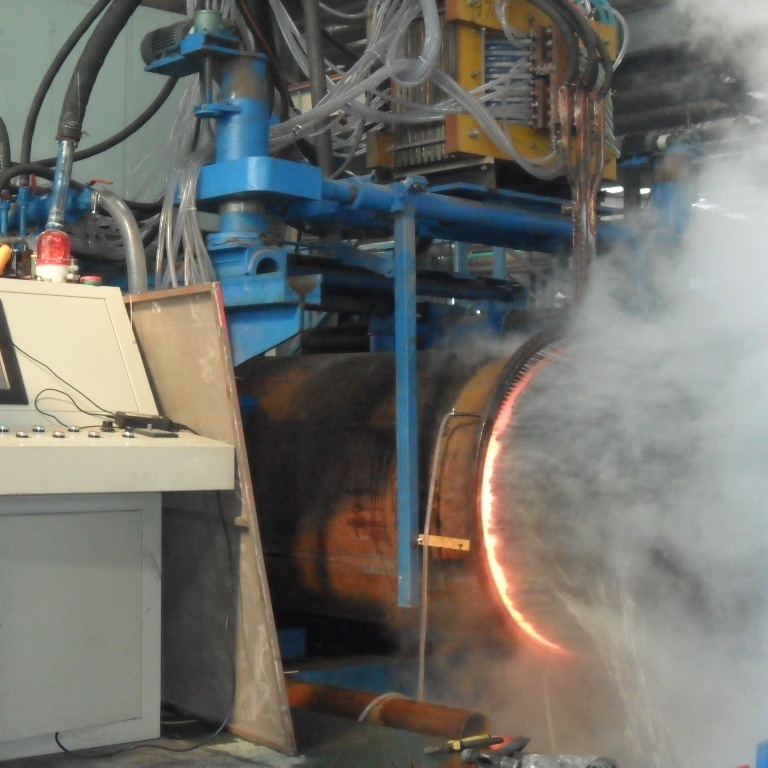

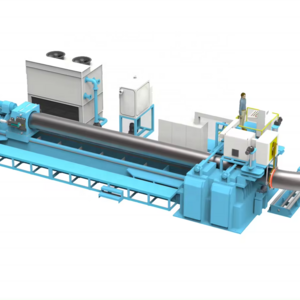

Pipe Hot Induction Heating Machine Hydraulic Tube Bending Machine For Oil Gas Industry

Automatic type hydraulic if pipe bender is equipped with mechanical part and electric controlling part. Mechanical part has four institutions: Power supply mechanism, clamp fixed institution, bend radius adjusting mechanism, feed mechanism.

Electrical part of If pipe bending machine consists of two systems: Heating system and PLC control system.

PLC control systemof If pipe bending machine :

The Siemens S7-200, using the industrial computer or touch screen , We developed a set of automatic control system from year 1994 according to the bending process : - Put the required bend geometry size, bending radius, bend Angle and raw material Numbers, material, heating required temperature and a series of data into the computer, let the computer has automatic tracking control according to those data, complete the tube bending process .

1. Using far infrared thermometer of IF pipe bending machine , sampling with one point or multiple point, One point ensure reliable temperature rise, process clear display and monitoring temperature rise situation all times.

2. Automatic tracking control of if pipe bending machine : To realize that when high voltage in network, temperature quick rise correspondingly, so achieve fast hydraulic pushing speed; If low voltage in network, temperature rise is slow, hydraulic pushing speed is slow correspondingly, Forming closed cycle, keep relative balance.

3. Pipe bending process of if pipe bending machine : The computer records pipe bending situation at all times. When bending angel of the pipe arrived in required place, the computer stop and alarm automatically, the whole data and image of bending process can be stored and printed.

| Name | Pipe Hot Induction Heating Machine Hydraulic Tube Bending Machine For Oil Gas Industry |

| Origin | Hebei,China |