- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

GA-2001-A

-

Product name:

-

Programmable Temperature Humidity Chamber

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GONOAVA

-

Model Number:

-

GA-2001-A

-

Product name:

-

Programmable Temperature Humidity Chamber

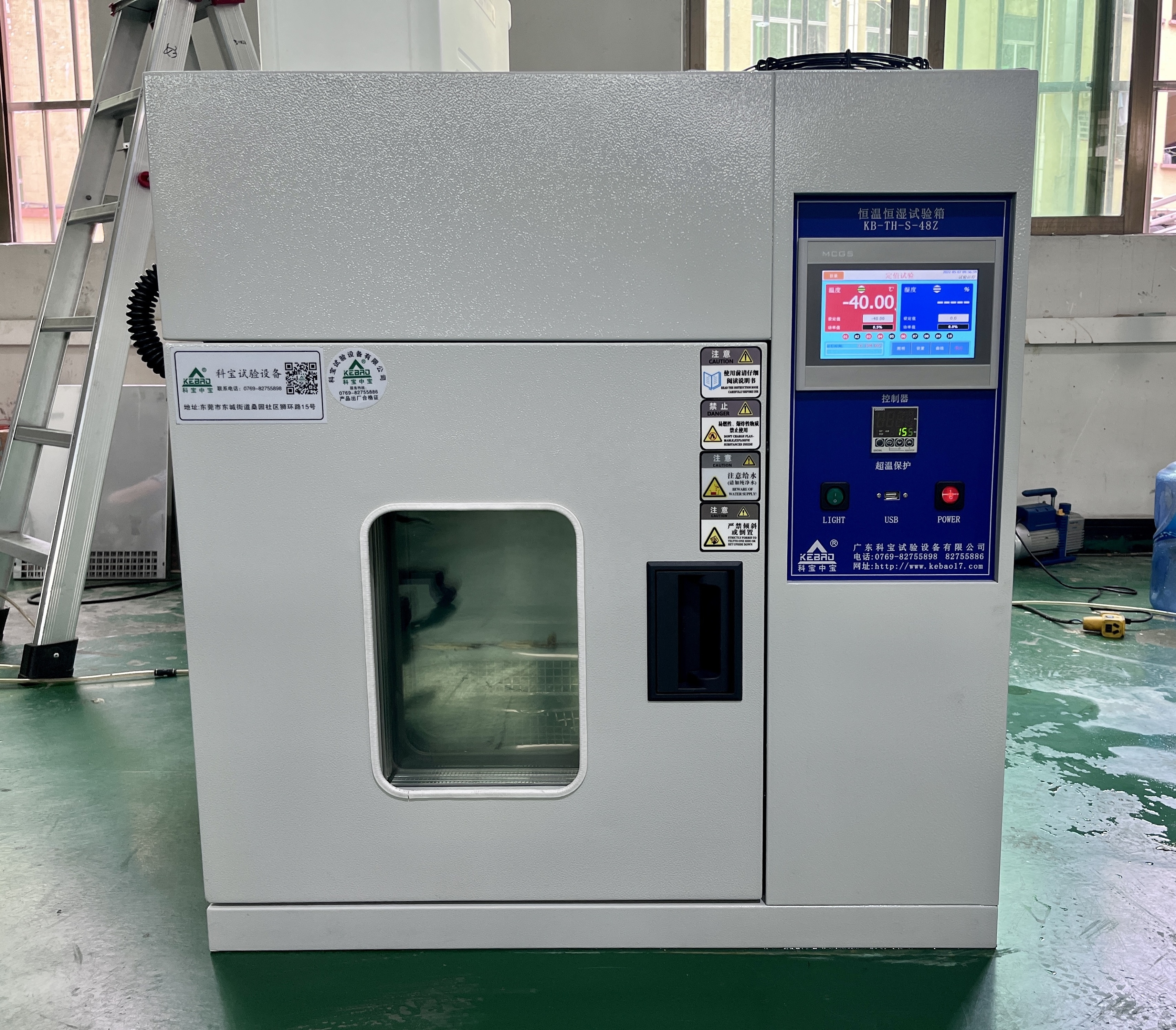

Programmable Temperature Humidity test Chamber 36L

1.Design Standard:

|

GB 1 1158 |

High Temperature Test Chamber Technical Condition |

|

GB 1 0589-89 |

Low Temperature Test Chamber Technical Condition |

|

GB 1 0592-89 |

High - low Temperature Test Chamber Technical Condition |

|

GB / T 10586-8 9 |

Damp Heat Test Chamber Technical Condition |

|

GB / T2423. 1-20 |

Low Temperature Test Chamber Test Methods |

|

GB / T 2423.2-20 |

High Temperature Test Chamber Test Methods |

|

GB / T 2423.3-93 |

Damp Heat Test Chamber Test Methods |

|

GB / T 2423.4-93 |

Alternating Damp - Heat Test Methods |

|

GB / T 2423.22-2 |

Temperature Changing Test Methods |

|

IEC 6006 8-2- 1. |

Low Temperature Test Chamber Test Methods |

|

IEC 60068-2-2 . |

High Temperature Test Chamber Test Methods |

|

GJB 150.3 |

High Temperature Test Methods |

|

GJB 1 50.4 |

Low Temperature Test Methods |

|

GJB 150.9 |

Damp Heat Test Methods |

Programmable Temperature Humidity test Chamber 36L

2. Uses

This equipment can simulate different environment condition. It's appropriate for testing material

performance, such as resist heat, resist dry,resist humidity and resist cold. That can define performance of

material.

Programmable Temperature Humidity test Chamber 36L

3. Function

It simulates the products in the chamber where the climate

condition of different temperature and humidity, such as high-low

operation and storage, temperature cycling, high-low temperature

and high-low humidity, moisture condensation etc. to check its

adaptability and changing performance.

It’s required to conform to international regulation (IEC, JIS, GB,

MIL…) to reach the consistency (including test schedule, condition,

method) under the international standard.

Programmable Temperature Humidity test Chamber 36L

4. Sample application

The chamber applies to:

compatibility test for store, transportation and application of

electric, electronic products, unit components, parts and other

materials under high or low temperature.

The following samples are prohibited to be tested and stored:

- Inflammable , explosive and other volatile substances;

- Corrosive substance;

- Biont;

- Strong electromagnetic emission source.

Programmable Temperature Humidity test Chamber 36L

5. Volume, size & weight

| Volume | 36L |

| Internal size | W 350 x H300 x D350mm |

| Exterior size | W900 x H760 x D920mm |

| Weight | 170KG |

Programmable Temperature Humidity test Chamber 36L

6. Performance

6.1. Test condition

Temperature : +25℃, Humidity: ≤85%, no samples in the chamber

6.2. Test method

GB/T 5170.2-1996 Temperature test chamber

GB/T5170.5-1996 Temperature and humidity test chamber (only

temperature and humidity)

6.3. Temperature range : -20℃→+150℃ (adjustable)

6.4. Temperature fluctuation : ±0.5℃

6.5. Temperature accuracy distribution : ±2.0℃

6.6. Humidity range: 30% ~ 98%R.H (temperature at 20℃-85℃)

6.7. Humid. fluctuation : ±2.5%R.H.

6.8. Humidity accuracy distribution : ±3.0%.

6.9. Heat-up time : -20℃ → +150℃ Heat up for 2-4.0℃/min

6.10. Cooling time : +150℃→ -20℃ Cooling for 0.7-1.0℃/min

6.11. Load condition : Testing space is not more than 3/4 of the total space, no heating

6.12. Sample holder : Stainless steel punching stencil

6.13. Relative humidity and temperature control range (refer to fig.)