- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AUTO

-

Model:

-

WJP75B-1000

-

Product Format:

-

Single layer

-

Sheet Width:

-

≤880mm

-

Tolerance of Sheet Thickness:

-

±0.015mm

-

Max. Output:

-

≤450kg/h

-

Production Line Speed:

-

≤30m/min

-

Total Power:

-

≤280kw

-

Feature:

-

A set of equipment can complete a complete production process

-

Output (kg/h):

-

1 - 400 kg/h

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

34:1

-

Screw Speed (rpm):

-

280 rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AUTO

-

Model:

-

WJP75B-1000

-

Product Format:

-

Single layer

-

Sheet Width:

-

≤880mm

-

Tolerance of Sheet Thickness:

-

±0.015mm

-

Max. Output:

-

≤450kg/h

-

Production Line Speed:

-

≤30m/min

-

Total Power:

-

≤280kw

-

Feature:

-

A set of equipment can complete a complete production process

-

Output (kg/h):

-

1 - 400 kg/h

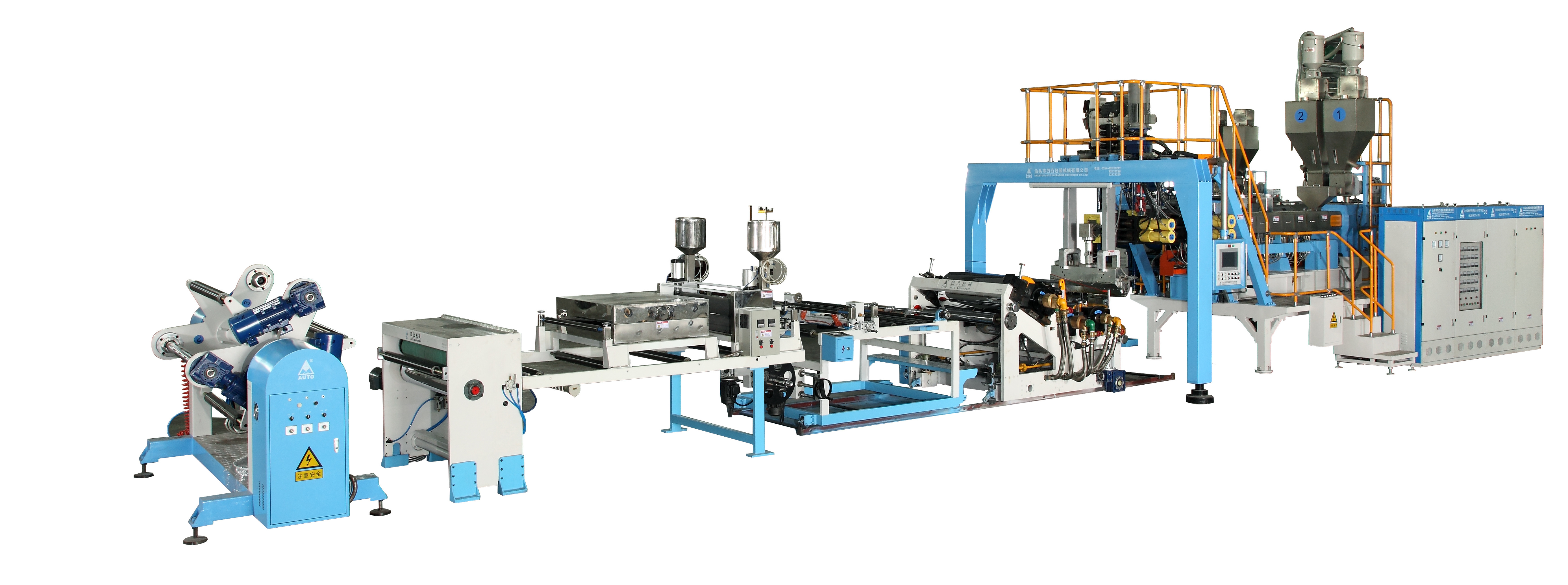

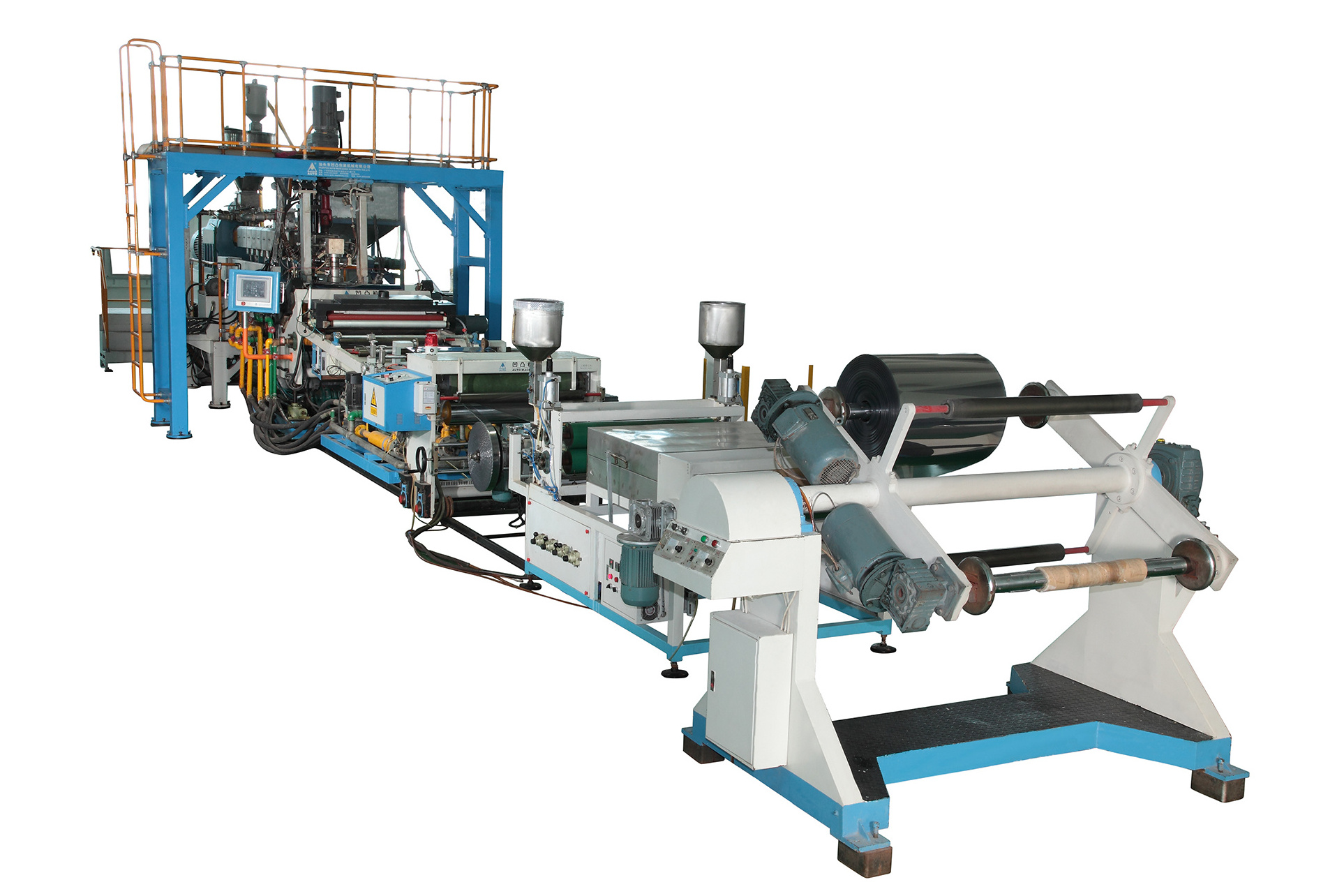

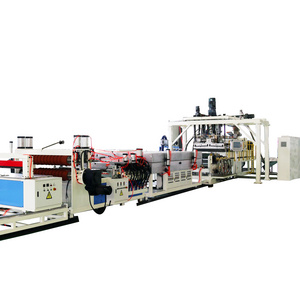

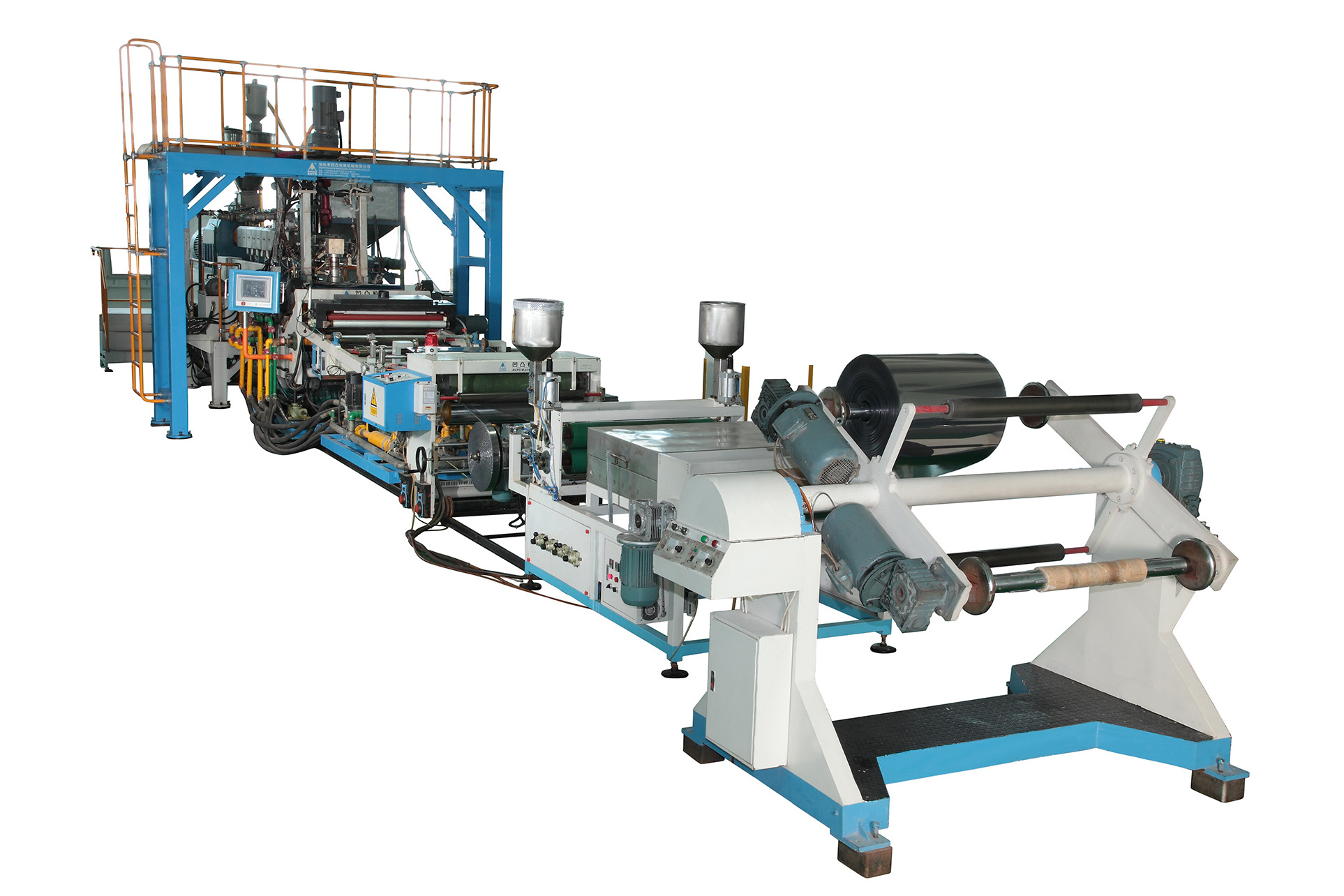

Summary:

The main machine of the equipment is one set of twin-screw plastic extruder, which can be used

for manufacturing line of PET sheet materials and can reduce energy consumption drting of materials drying of materials. Besides, the extruder can also be used to manufacture re-grinding materials and starch-base materials.

Feature of twin screw plastic extruder:

1. The screw element adopts conjugate type double thread screw with computer optimization design and precision machining. Besides, the screw is designed with multivariate combination modular construction, which has superior self-cleaning and interchangeability.

2. Based on years of screw configuration design experience, AUTO can perform optimal configuration of screw elements combination with the help of software technology. Therefore, it can realize transmission of plasticizing materials, mixed refining, shearing and dispersion, homogenization, volatilization and devolatilization, keep pressure and extrusion and other functions according to customer’s materials and processing technology.3. The machine barrel is designed with two vacuum exhausting connectors ensuring fully discharging of water vapor and other volatile gases.

4. The twin screw plastic extruder is designed with melt dosing pump ensuring quantitative output with steady pressure, which can also help realize automatic closed-loop control of pressure and speed.

5. The total machine adopts PLC control system, which can realize automatic control for parameter setting, date operation, feedback, alarming and other functions.

|

Model |

WJP75B-1000 |

|

Suitable Material |

PET |

|

Sheet Width |

≤880mm |

|

Thickness of Sheet |

0. 15-1.5 mm |

|

Tolerance of Sheet Thickness |

±0.015mm |

|

Max. Output |

≤450kg/h |

|

Production Line Speed |

≤30m/min |

|

Total Power |

≤280kw |

1. Q: Are you a factory or trading company?

A: We are a factory.

2. Q: How does your factory do regarding quality control?

A: We have a special QC department in charge of products' quality.

3. Q: How long is the warranty period?

A: All of our machiner have one year warranty.

4. Q: What's the main market of your company?

A: We have customers all over the world.

5. Q: How much production capacity of your company one year?

A: This depends on your needs.

6. Q: Can we visit your machine operation in your factory?

A: We have own plastic products company, you can see all the machine operation.

7. Q: Where is your factory located? How can we visit there?

A: Our factory is located in Shantou City, Guangdong Province, China,

about 50 minutes from Guangzhou by air. We offer transportation service.