- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

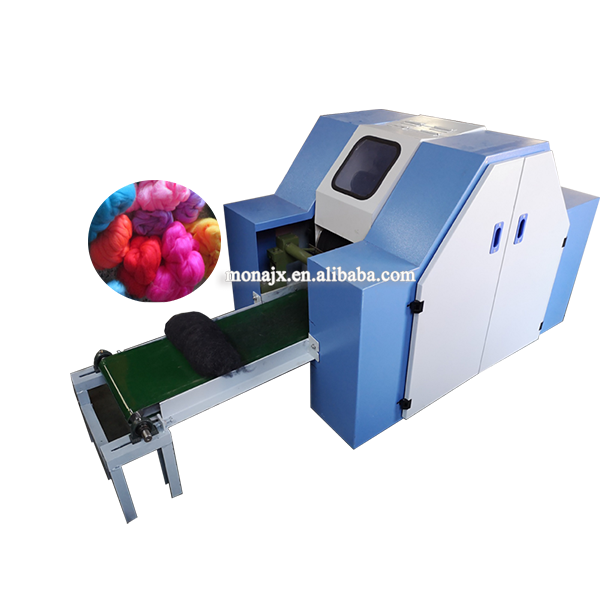

Small cotton Wool Carding Machine

-

Application:

-

Textile carding machine

-

Features:

-

wool/fiber combing machine

-

Raw Material:

-

cotton, fiber, wool,etc.

-

Function:

-

carding machine

-

Key words:

-

Sliver Knitting Machine Small Carding Machine for Wool

-

Features 2:

-

Dustless

-

Production Capacity:

-

10-15kg/hr

-

Color:

-

Blue or White

-

Working Width:

-

360mm

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Place of Origin:

-

China

-

Weight:

-

500 KG

-

Product name:

-

Small cotton Wool Carding Machine

-

Application:

-

Textile carding machine

-

Features:

-

wool/fiber combing machine

-

Raw Material:

-

cotton, fiber, wool,etc.

-

Function:

-

carding machine

-

Key words:

-

Sliver Knitting Machine Small Carding Machine for Wool

-

Features 2:

-

Dustless

-

Production Capacity:

-

10-15kg/hr

-

Color:

-

Blue or White

-

Working Width:

-

360mm

Product Description

This machine belongs to the domestic first, carding all kinds of Pure wool, rabbit hair,

chemical fiber to wool top or wool web, then used for wool mills, semi-worsted plant dedicated proofing.

chemical fiber to wool top or wool web, then used for wool mills, semi-worsted plant dedicated proofing.

Features Small Wool Carding Machine

The machine is composed of frame of machine,flat curtain for feeding,licker-in,

cylinder,working roller, stripping roller, doffer, chopper and so on.

(1). The frame parts are composed of a frame and a wall board, which is used for fixing all the rollers and the driving parts,

supporting feet, motor and others,to ensure the smooth running of the machine.

(2). The flat curtain part is composed of a drive shaft, driven shaft, leather curtain and a transmission motor, so as to ensure

the uniform feeding speed of the raw material.

(3). The licker-in parts is composed of roller, needle cloth, fixing seat,the spacing between licker-in roller and the front

feeding roller is suitable.This parts is used to remove coarse wool and impurities.

(4). The cylinder parts composed of a roller,needle cloth, fixing seat and main motor. The spacing between cylinder and the front

licker-in roller is suitable. And the spacing between working roller and stripping roller is also need to adjust.All about this

will be well adjusted when the machines shipped to the Buyer.This part is mainly used to open raw materials.

(5). The working roller and stripping roller parts will working with cylinder, to open the wool again more fluffy.

(6). The doffer parts composed of a roller,needle cloth, fixing seat,the spacing between doffer and the front cylinder is

suitable.to ensure that the wool on cylinder can be transferred to the next working roll.

(7). The chopper part is composed of a chopper arm, chopper holder and a chopper blade,which is the main used to strip the wool

from doffer.

cylinder,working roller, stripping roller, doffer, chopper and so on.

(1). The frame parts are composed of a frame and a wall board, which is used for fixing all the rollers and the driving parts,

supporting feet, motor and others,to ensure the smooth running of the machine.

(2). The flat curtain part is composed of a drive shaft, driven shaft, leather curtain and a transmission motor, so as to ensure

the uniform feeding speed of the raw material.

(3). The licker-in parts is composed of roller, needle cloth, fixing seat,the spacing between licker-in roller and the front

feeding roller is suitable.This parts is used to remove coarse wool and impurities.

(4). The cylinder parts composed of a roller,needle cloth, fixing seat and main motor. The spacing between cylinder and the front

licker-in roller is suitable. And the spacing between working roller and stripping roller is also need to adjust.All about this

will be well adjusted when the machines shipped to the Buyer.This part is mainly used to open raw materials.

(5). The working roller and stripping roller parts will working with cylinder, to open the wool again more fluffy.

(6). The doffer parts composed of a roller,needle cloth, fixing seat,the spacing between doffer and the front cylinder is

suitable.to ensure that the wool on cylinder can be transferred to the next working roll.

(7). The chopper part is composed of a chopper arm, chopper holder and a chopper blade,which is the main used to strip the wool

from doffer.

Used for

Specification

|

Model

|

MN-CC-360

|

|

Voltage

|

220v/380v or customize as your request

|

|

Capacity

|

10-15kg/h

|

|

Floor space

|

1500*900mm

|

|

Machine width

|

360mm

|

|

Motor

|

6 stage 1.1kw(Motor power depending on user conditions)

|

|

Machine Weight

|

500kg

|

|

Dimenssion

|

1500*1000*1000mm

|

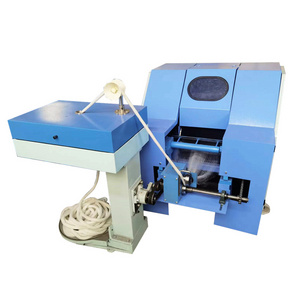

Machine picture

Packing &delivery

Hot sale

Hot Searches