- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

500x500x1200mm

-

Weight (T):

-

3 T

-

Power (kW):

-

200

-

Applicable Industries:

-

graphite powder

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

3000 degree induction heating graphitization furnace

-

Application:

-

Sintering furnace

-

Capacity:

-

300L

-

Working size:

-

500X500X1200mm

-

Max. working temperature:

-

2500℃

-

Input power:

-

380v

-

Temperature uniformity:

-

±10℃

-

Structure:

-

Horizontal type

-

Working atmosphere:

-

Vacuum or argon inert gas

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

NUOTIAN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

500x500x1200mm

-

Weight (T):

-

3 T

-

Power (kW):

-

200

-

Applicable Industries:

-

graphite powder

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

3000 degree induction heating graphitization furnace

-

Application:

-

Sintering furnace

-

Capacity:

-

300L

-

Working size:

-

500X500X1200mm

-

Max. working temperature:

-

2500℃

-

Input power:

-

380v

-

Temperature uniformity:

-

±10℃

-

Structure:

-

Horizontal type

-

Working atmosphere:

-

Vacuum or argon inert gas

Sintering furnace is a batch-type of induction heating furnace, m ainly used in the sintering of hard alloy and powder metallurgy industry producing size of silicon carbide powder, silicon carbide seal ceramic sintering, pressureless sintering of silicon carbide and titanium carbide powder and vanadium carbide powder and metal powder and composite metal powders.

Techn ology parameter:

|

Model |

NT I -SJL-54W

|

NT I -SJL-98W

|

NT I -SJL-300W

|

NT I -SJL-484W

|

|

Working size |

300*300*600 |

350*350*800 |

500*500*1200 |

550*550*1600 |

|

Max.capacity |

54 |

98 |

300 |

484 |

|

Rated power ( KW ) |

120 |

160 |

200 |

250 |

|

Common temperature ( ℃ ) |

2400 ℃ |

|||

|

Ultimate temperature ( ℃ ) |

2500 ℃ |

|||

|

Temperature niformity ( ℃ ) |

≤±10 ℃ |

|||

|

Rated voltage (V) |

380V

|

|||

|

Vacuum ultimate (Pa) |

10pa(vacuum state) |

|||

|

Control type |

Manual control/automatic control |

|||

|

Vacuum system |

Rotary vane vacuum pump or slide valve and Roots vacuum pump |

|||

|

Working environment |

Vacuum, Ar2 and such inert gas |

|||

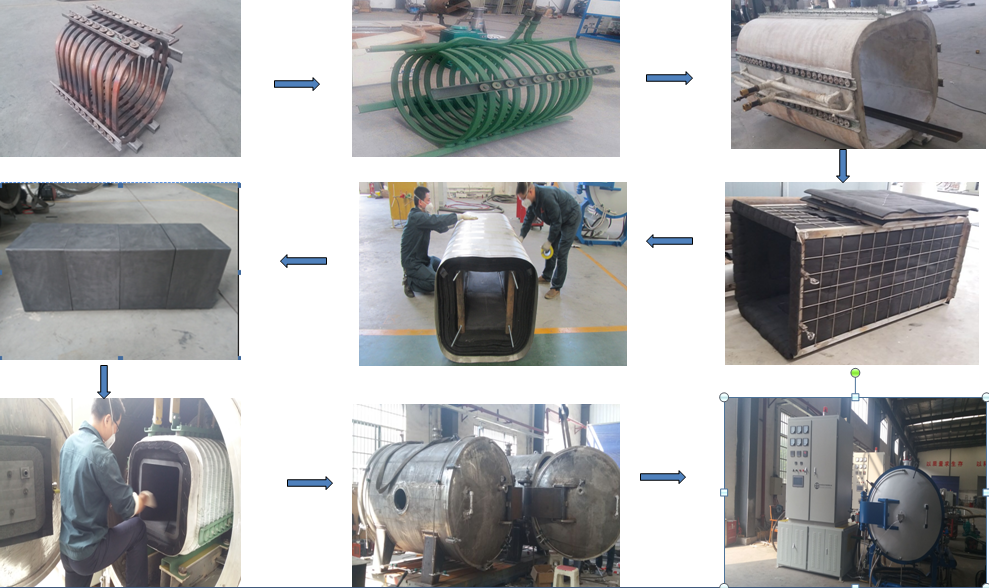

Picture of production process:

Producing work-piece sample: