- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Amitycare

-

Power:

-

4.5KW

-

Weight:

-

1500 kg

-

Application:

-

Drain Pipe

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Handle way:

-

automatic

-

Diameter:

-

300-1200mm

-

Color:

-

customized

Quick Details

-

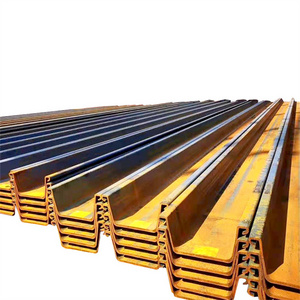

Pipe Material:

-

Carbon steel

-

Applicable Industries:

-

centrifugal spinning machine

-

Production Capacity:

-

100%

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Amitycare

-

Power:

-

4.5KW

-

Weight:

-

1500 kg

-

Application:

-

Drain Pipe

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Handle way:

-

automatic

-

Diameter:

-

300-1200mm

-

Color:

-

customized

| The distance between two wheel | 2000mm |

| The distance between central of wheel | 950mm-1200mm |

| Diameter of wheel | 600mm |

| Diameter of axle | 110mm-125mm |

| Automatic controller for centrifugal concrete pile machine |

|

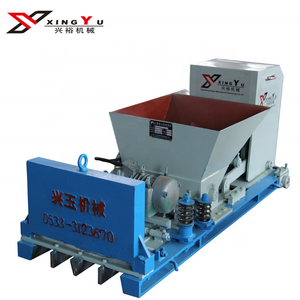

Prestressed concrete /electric pole spinning machine

is designed and manufactured for centrifugal reinforced concrete pipe in single mould spinning for largre diameter pipe and multiple mould spinning for small and medium size mould spinning .The machine is totally custom-made, and specification is available based on endusers' application.

1.Unique"slot" design, change the screw limit between the bearing support and base plate with card solt and bolt limit. Both up and down sides of the spinning machine panel, undersurface and two sides of bearing support go through fine machining.

2.Connection shaft is whole shaft, to avoid stress concentration brought by shaft diameter changes,resulting in the phenmenon of "shaft-broken".

3.The limit side of the support wheel is removable. It is convenient for users to replace.

4.Frequency-conversion cabinet of spinning machine records process parameter of each pipe and output reports,provides the office computer data communication interface .