- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YUGONG

-

Dimension(L*W*H):

-

1080*740*880mm

-

Name:

-

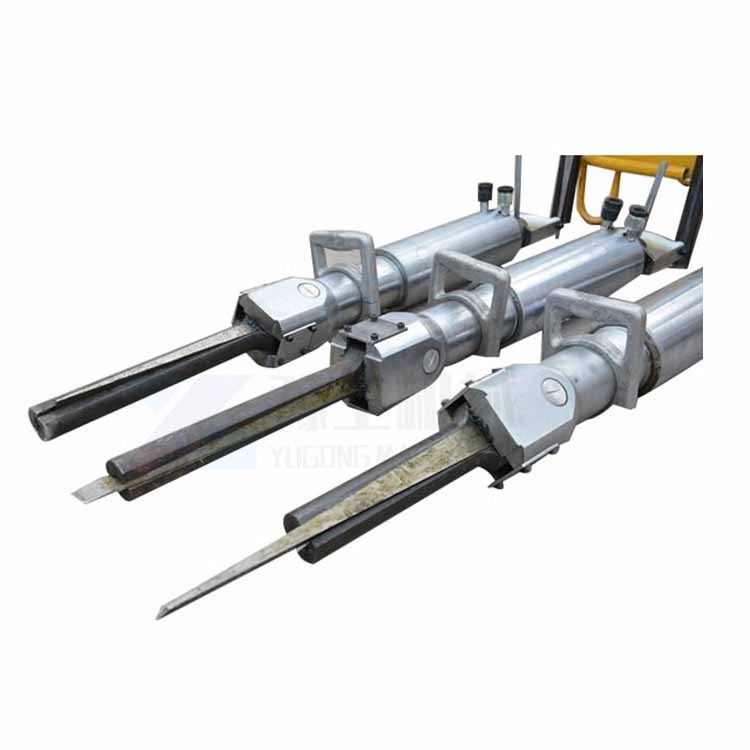

Hydraulic Rock Splitter

-

Product name:

-

Mobile Hydraulic Splitting Rock Splitter

-

Key word:

-

Hydraulic Rock Splitter Used

-

Usage:

-

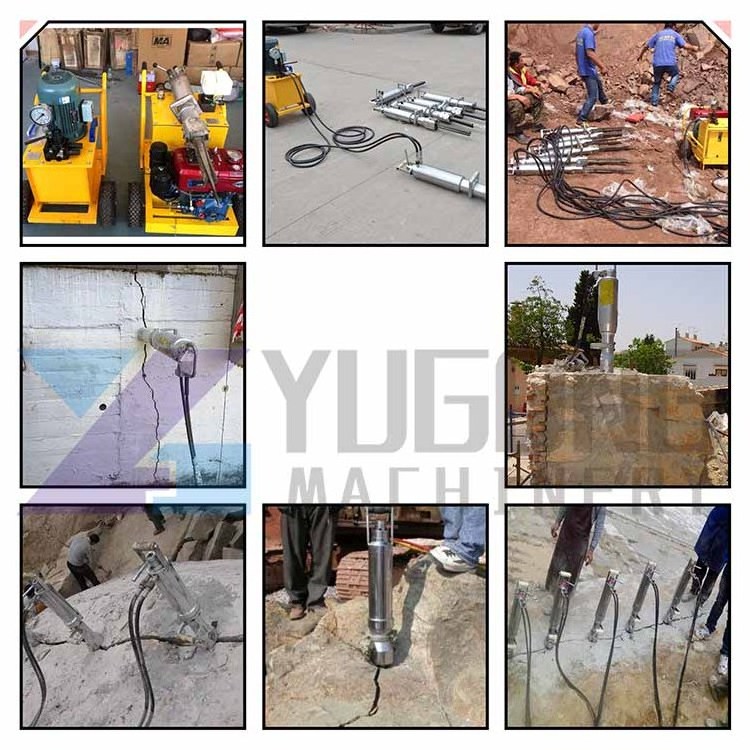

Splite Rock, Concrete Crushing, Block Quarrying

-

Item:

-

Hydraulic Rock Breaker

-

Working Medium:

-

No. 46 or 68 antiwear hydraulic oil

-

Pump pack type:

-

Diesel Hydraulic Pump, Electric Oil Pump

-

Work pressure:

-

55-60Mpa

-

Splitting Diameter:

-

42-45mm

-

Wedge Length:

-

250/350/450mm

Quick Details

-

Weight (KG):

-

200

-

Application:

-

concrete rock splitter

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Dimension(L*W*H):

-

1080*740*880mm

-

Name:

-

Hydraulic Rock Splitter

-

Product name:

-

Mobile Hydraulic Splitting Rock Splitter

-

Key word:

-

Hydraulic Rock Splitter Used

-

Usage:

-

Splite Rock, Concrete Crushing, Block Quarrying

-

Item:

-

Hydraulic Rock Breaker

-

Working Medium:

-

No. 46 or 68 antiwear hydraulic oil

-

Pump pack type:

-

Diesel Hydraulic Pump, Electric Oil Pump

-

Work pressure:

-

55-60Mpa

-

Splitting Diameter:

-

42-45mm

-

Wedge Length:

-

250/350/450mm

Manual hydraulic stone splitter machine rock breaking chemical tool to break rocks

Yugong is specialized in the rock splitting machine, including the small hydraulic rock splitter and excavator mounted rock splitter . Rock splitter is a kind of machine for splitting rock. It can split all kinds of natural stones, rock, granite, marble mining & quarrying and also break concrete. The rock splitting tool is mostly used in construction, decoration, engineering construction, ore mining, secondary disintegration of large ore, partial and total removal of concrete components. Safety, fast speed, adjustable oil pressure.

The following is mainly about the small hydraulic rock splitting machine.

| Splitting Gun | |||

| Model | YG-250 | YG-350 | YG-450 |

| Wedge Length | 250mm | 350mm | 450mm |

| Piston Stroke | 90/220mm | 90/220mm | 90/220mm |

| Drilling depth | >500mm | >700mm | >900mm |

| Punching Diameter | 42mm | 45mm | 45mm |

| Crack width | 10-20mm | 10-20mm | 10-20mm |

| Cleavage Time | 10-15/s | 10-15/s | 10-15/s |

| Splitting Force | 500t | 800t | 800t |

| Weight | 30kg | 30kg | 30kg |

| Hydraulic Pump Pack | ||

| Engine | Diesel Hydraulic Pump | Electric Oil Pump |

| Power | 6HP/8HP/12HP | 4KW |

| Weight | 170KG | 150KG |

1. Quarry splitter machine can be for open-pit stone mine, mining and excavation;

2. Remove redundant reinforced concrete structures, concrete machine beds and plinths, broken and demolished;

3. It is a stone-breaking tool in road-building;

4. Concrete breaker, concrete wall, concrete block splitting, demolition and crushing;

5. Blocks of stone, secondary decomposition;

6. Rock breaking tools for building foundation, rock broken;

7. Demolition equipment for tunnel, rock breakage, tunneling;

8. Tower Foundation, Shaft Excavation.

Hydraulic splitter is composed of two parts: pump station(electric type or the diesel engine type) and splitter . When working, the high-pressure oil from pump station drives the cylinder, which generates huge thrust. The middle wedge in the wedge group is pushed forward, and the reverse wedge is pushed to both sides to split the splitted object.

The concrete implementation steps are as follows:

1. First drill hole in stone,

Diameter of the hole:YG-250:42mm,YG-350 and YG-450:46mm

Min. Depth of the hole:YG-250:500mm,YG-350:700mm,YG-450:900mm

2. Then insert hydraulic cylinders which is contain wedge and feathers. Start engine to provide hydraulic pressure.

3. Repeat the process until the whole structure is fractured into smaller sections and ready for removal.

How to Choose Hydraulic Rock Splitter?

1. Engine of pump pack: Do you need the electric engine or diesel engine ?

2. Quantity of splitter: How many splitter guns do you need?

3. Length of wedge: 250mm, 350mm or 450mm?

4. Length of oil tube: How far is it from pump to the rock in the working area?

1. Enormous splitting force up to 800 tons, vibration free;

2. Dust free and near silent operation,Light weight and Easy handling;

3. Different sizes of counter wedge and center wedge can use on the same splitter.

1. Wrapped by protective film;

2. Packed by standard import & export wooden cases or carton boxes;

3. Customized according to your requirement.

Delivery Time

Within one week

Shipping

Port

: Tianjin, Qingdao, Shanghai,Guangzhou or other ports according to your requirements.

Sea freight

: FOB/CIF/DDU quotation are all available.

Transport method

: By logistics; by automobile; by train; by shipping; by air etc.

Notes

1. Drill hole 40-42mm using the

rock drill

, drilling depth is not less than 50cm (otherwise the middle wedge is easy to break). YG-350 type drill hole with 46 bits. After drilling, it is necessary to clear the hole, clear the slag and water, and use No. 46 hydraulic oil.

2. Don't shake the splitting gun before the hydraulic oil is returned to the oil. When pulling out the splitting gun, be careful not to shake left and right. Don't use it as a crowbar to avoid damaging the splitting block.

3. Clean up the splitting block and the intermediate wedge in time after use. Do not use water to avoid rust. Use butter to smear the splitting block and the intermediate wedge before using the splitting gun to maintain lubrication.

4. When the splitter can't pull out, the splitting stones are too big and the cracks are too small to be stuck, and they are broken with brazes.

Other matters needing attention please contact us.

Related Products