- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 50HZ

-

Power:

-

4.5kw

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PF

-

Model Number:

-

PFCP-297C

-

Dimension(L*W*H):

-

3200x1100x1900mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main Function:

-

A4 Paper wrapping

-

Machine type:

-

Wrapping machine

-

Packing material:

-

Printed Film

-

Paper type:

-

A4 copy paper

-

Power supply:

-

220V 50HZ 4.5Kw

-

Packing speed:

-

12-15 packs/ min

-

A4 paper size:

-

297mmx210mm(500 sheets)

-

Quality system:

-

ISO and CE approved

-

Key words:

-

A4 paper wrapping machine

-

MOQ:

-

1 unit

-

Certification:

-

CE/ISO9001

Quick Details

-

Function:

-

Wrapping

-

Packaging Type:

-

Foil

-

Packaging Material:

-

Paper

-

Voltage:

-

220V 50HZ

-

Power:

-

4.5kw

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PF

-

Model Number:

-

PFCP-297C

-

Dimension(L*W*H):

-

3200x1100x1900mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main Function:

-

A4 Paper wrapping

-

Machine type:

-

Wrapping machine

-

Packing material:

-

Printed Film

-

Paper type:

-

A4 copy paper

-

Power supply:

-

220V 50HZ 4.5Kw

-

Packing speed:

-

12-15 packs/ min

-

A4 paper size:

-

297mmx210mm(500 sheets)

-

Quality system:

-

ISO and CE approved

-

Key words:

-

A4 paper wrapping machine

-

MOQ:

-

1 unit

-

Certification:

-

CE/ISO9001

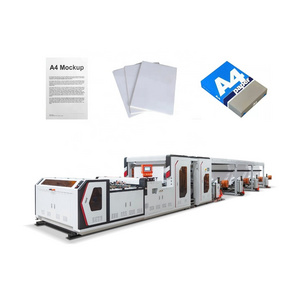

A4 copy paper wrapping machine

Rolling packing material Staion:

Rolling packing material Staion:

Pack station 500pcs each sheet:

Final product after packed

Main technical parameters:

|

Production capacity: |

12-15 (packs/min) |

|

A4 copy paper size(standard): |

297mmx210mm ( 500 sheets ) |

|

Temperature |

110-140 degree |

|

Voltage: |

220v 50hz.one phase and we can do it as per your requirement. |

|

Power: |

4.5kw |

|

Compressed air: |

0.4Mpa |

|

Roll diameter |

Inner diameter of roll: diameter 76mm Max diameter: diameter < 800mm |

|

Overall dimensions: |

3200x1100x1900mm |

|

Weight: |

1200kg |

|

Package material |

Printed film. |

Performance and structure features:

1/Main structure is driven by a series of cams and connecting rods and working accessories to finish the packaging. High stability, low noise.

2/Applying frequency conversion with multi-function digital non-ploy speed, adopting siemens PLC program controlled.

3/Touch screen realizing human-machine interface.

4/ if package material is printed film photocell sensor will be provided so as to reduce the packing cost and also improve cutting accuracy of color film, wrapping effect and sealing performance.

Contacting way:

Peter Chen

General Manager