- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5000*860*1750 mm

-

Power (kW):

-

25kw

-

Weight (KG):

-

1800 kg

-

Panel Feed Speed(m/min):

-

60m/min

-

Name:

-

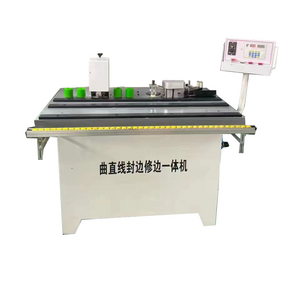

PVC Edge Banding Machine

-

Application:

-

Woodworking Plywood Veneer Production

-

Keywords:

-

Edge Banding Machine

-

Total power:

-

12kw

-

Running speed:

-

12-20m/min

-

Panel thickness:

-

10-60mm

-

Thickness of edge banding:

-

0.4-6mm

-

Working air pressure:

-

0.8Mpa

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Grandio CNC

-

Voltage:

-

220V 380V

-

Dimension(L*W*H):

-

5000*860*1750 mm

-

Power (kW):

-

25kw

-

Weight (KG):

-

1800 kg

-

Panel Feed Speed(m/min):

-

60m/min

-

Name:

-

PVC Edge Banding Machine

-

Application:

-

Woodworking Plywood Veneer Production

-

Keywords:

-

Edge Banding Machine

-

Total power:

-

12kw

-

Running speed:

-

12-20m/min

-

Panel thickness:

-

10-60mm

-

Thickness of edge banding:

-

0.4-6mm

-

Working air pressure:

-

0.8Mpa

Product Description

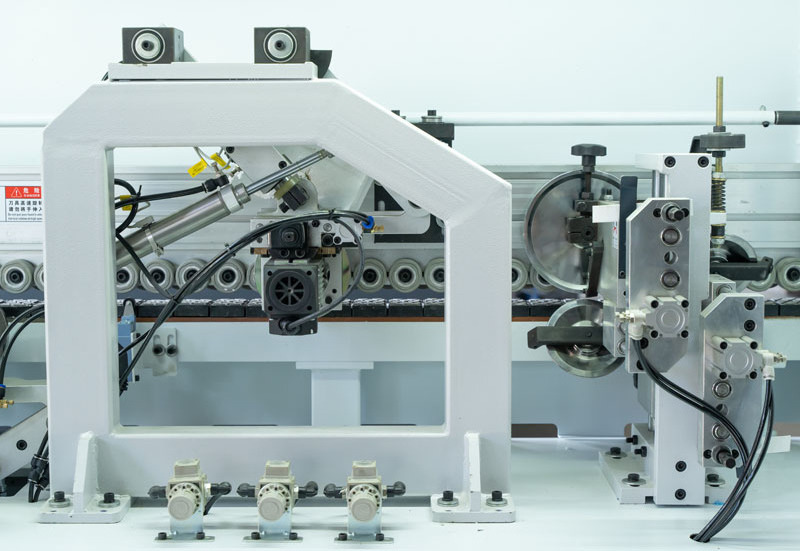

Automatic PVC Edge Banding Machine Introduction

1.Adopt domestic famous motor and high quality electrical components.

2.The machine can be customized. Auto cleaning, high precision, high efficiency.

3.Aluminum alloy beam is a relatively advanced method,precisione and straightness are far superior to cast iron.Stability and controlled ability are the most important,factors for an equipment to be part of production line.

4.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

Specification

Functions: 01. Pre-milling 02.Gluing 03.Front and end cutting 04.Rough trimming 05. Fine trimming 06.Corner rounding, 07.Scraping 08.Polishing

03. Front and end cutting

It is composed of front end trimming and back end trimming. It is controlled by Taiwan AirTac solenoid valve. It has a unique protection function of end trimming and plate bumping. It is cut off by a special saw blade to enhance the stability of end trimming.

It is composed of front end trimming and back end trimming. It is controlled by Taiwan AirTac solenoid valve. It has a unique protection function of end trimming and plate bumping. It is cut off by a special saw blade to enhance the stability of end trimming.

05. Corner Rounding

Can shaped the panel then looks more beautiful. The function is a necessary step for cabinet door

Can shaped the panel then looks more beautiful. The function is a necessary step for cabinet door

06. Scraping

Used to scrape the extra glue, to make the edges more smoother. It is equipped with dust collector pips.

Used to scrape the extra glue, to make the edges more smoother. It is equipped with dust collector pips.

Product Parameters

Our sideband machine adopts the latest technology and innovative design, with the following advantages:

Fast and accurate edge processing: Our machine can process edge bands of various materials at high speed, ensuring the accuracy and consistency of edge processing. Whether it is a straight edge band, a curved edge band, or an irregular edge band, our machine can easily handle it.

Automated operation: Our machines are equipped with advanced automation systems, which can achieve functions such as automatic feeding, automatic decoration, and automatic discharge, greatly reducing the time and labor costs of manual operations.

Efficient production: With high-speed processing capabilities, our sideband machine can achieve a processing speed of over 100 meters per minute, greatly improving work efficiency and production capacity.

Perfect edge quality: Our edge banding machine adopts advanced cutting tools and processing technology, which can achieve perfect edge fitting and anti warping, ensuring the beauty and durability of product edges.

In addition to the above advantages, our sideband machine also has a user-friendly operating interface and an intelligent fault alarm system, ensuring easy operation and timely resolution of potential problems.

Not only for our products, we also provide professional after-sales service and technical support for you. Our team will provide you with training, maintenance, and upgrade services to ensure that you can fully unleash the potential of your machine, improve production efficiency and quality.

|

Product name

|

GD-468J Automatic PVC Edge banding machine

|

|

Edge banding thickness

|

0.3-4mm

|

|

Edge banding height

|

12-60mm

|

|

Banding tape width

|

10-55mm

|

|

Mini work piece length

|

>=80mm

|

|

Mini Work piece width

|

>=60mm

|

|

Machine body

|

Heavy duty

|

|

Trimming

|

Pneumatic adjustment knife

|

|

End cutting

|

End cutting stable collision avoidance system

|

|

Scraping

|

Pneumatic knife adjustment with blowing

|

|

Voltage

|

220v 609Hz 3Phases

|

|

Weight

|

1200kg

|

|

Function

|

Straight edge banding

|

|

Applications

|

Straight-line gluing edge sealing of various wood boards (such as plywood and fiberboard, etc.)

|

|

Functions

|

Pre-milling---Preheating---Pressing/gluing---End cutting---Rough trimming and fine Trimming-- Corner rounding---Scraping---Polishing

|

Application

Automatic pvc edge banding machine application:

It can be used for whole house customization, panel furniture, kitchen dining room, oddice cabinet table,etc

The machine is suitable for the following boards: MDF, block board, solid wood board, particleboard, polymer door plates, plywood, pvc board, etc. Straight line edging and trimming.

It can be used for whole house customization, panel furniture, kitchen dining room, oddice cabinet table,etc

Packaging and Shipping

The wooden box is sealed and packaged for safe transportation and effectively prevent bumps.

Because the machinery is relatively heavy, shipping is generally chosen.

Shipping and payment methods can be negotiated with customer service

.

Hot Searches