- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8*4*7m

-

Voltage:

-

380v50hz 3phase

-

Power:

-

1.5+0.5kw

-

Raw material:

-

Wood, rice husk briquette,bamboo saw dust briquette ect

-

Carbonization time:

-

8 hours

-

Capacity:

-

3-4t/day

-

Cooling Time:

-

6-8 hours

-

Export country:

-

overseas

-

Fuel:

-

Raw Coal,firewood ect.

-

Installation:

-

Engineer Guide

-

Application:

-

making charcoal

-

Inner stove qty:

-

6 sets

-

Operation:

-

Electrical

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE/ISO

-

Weight:

-

7000kg

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

MINGYANG

-

Effective Volume:

-

2.75*6

-

Dimension(L*W*H):

-

8*4*7m

-

Voltage:

-

380v50hz 3phase

-

Power:

-

1.5+0.5kw

-

Raw material:

-

Wood, rice husk briquette,bamboo saw dust briquette ect

-

Carbonization time:

-

8 hours

-

Capacity:

-

3-4t/day

-

Cooling Time:

-

6-8 hours

-

Export country:

-

overseas

-

Fuel:

-

Raw Coal,firewood ect.

-

Installation:

-

Engineer Guide

-

Application:

-

making charcoal

-

Inner stove qty:

-

6 sets

-

Operation:

-

Electrical

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE/ISO

-

Weight:

-

7000kg

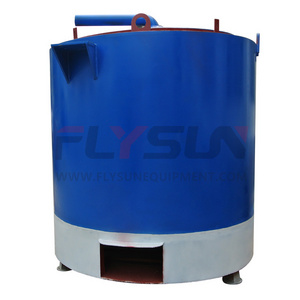

Commerical Industrial Chacoal Powder Making Machine Used Carbonization Stove For Sale

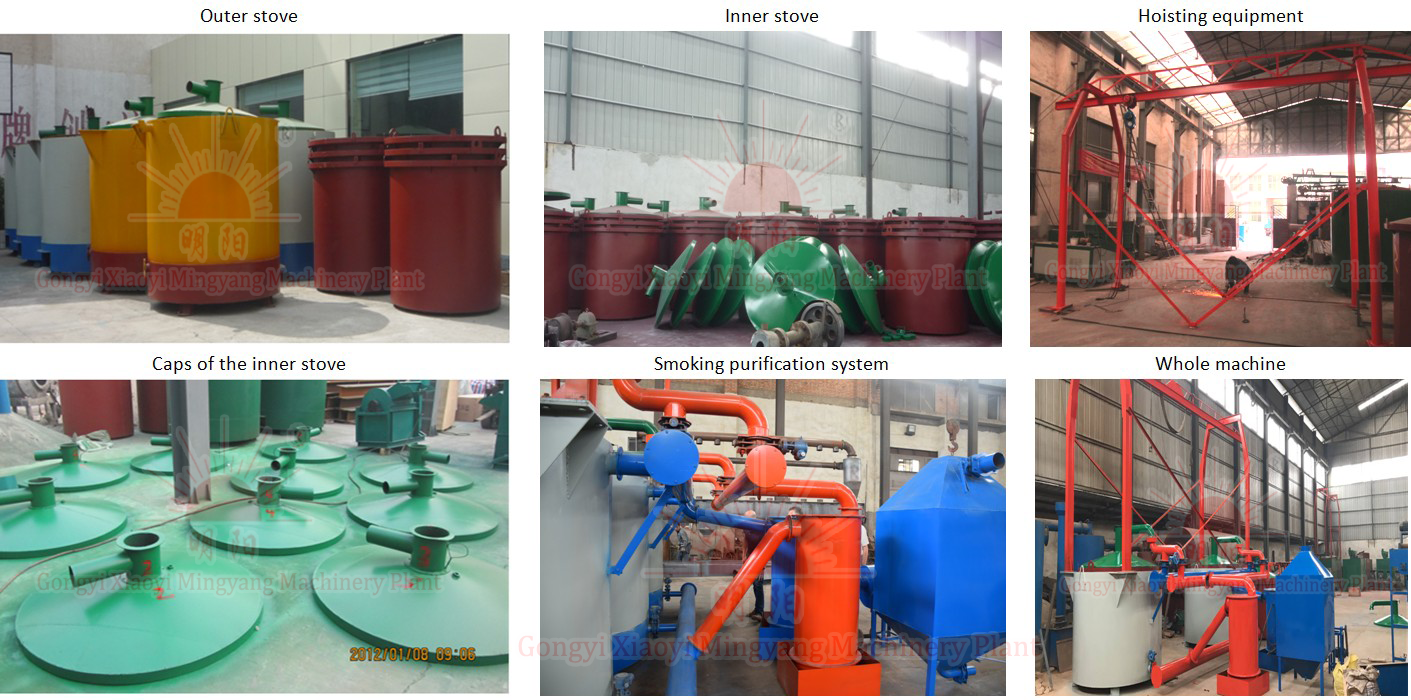

(1) Outer stove

includes heating room (for heating the inner stove), furnace body and heat-keeping layer (it is made of the heat insulating material)

(2) Inner stove

Consist of the stove tank body and the sealed top cap. They are made of the heat resistance thermal steel, three inner stove can be stacked together for saving space and shipping cost.

(3) Smoking recycle tube

During the process of carbonizing, there will be some smoke.( can be burning) the smoke can be collected and returned to the furnace.

(4) Purification tank

This system is consisting of purification tank and the exhaust-heated cycle pipe.

(5) Hoisting equipment

it include the steel hoisting frame and the E-hoist .And it is easy for loading and unloading the stove.

Operation instruction about Commerical Industrial Chacoal Powder Making Machine Used Carbonization Stove For Sale

1.Installation

Install the pipes correctly according to the numbers indicated, then place the furnace in the appropriate area to start production.

2. Preparation

-Remove from the oven and place it near the coal storage area.

-Open the oven lid, tilt it and place raw coal in the oven.

-When finished, cover the oven and lift it into the stove.

-Cover the edges with sand and then start carbonizing.

3. carbonization

Ignite and start carbonization, which is performed by carbonization technology.

4. After carbonization

After the carbonization is completed, adjust the smoke valve to stop the carbonization in the oven to complete the carbonization.

5. Sealed cooling

Cover the oven and cool it in a cooling area.

6.recycled carbon

Add another prepared oven and continue to carbonize. The procedures and techniques are the same as those described above.

7. Remove the carbonized material

After the carbide is completely cooled, open the attachment to completely remove it, and then place it in the raw material again for circular carbonization.

1.Crush the raw material into small pieces (diameter is about 3-5mm);

2.Dry the material by machine or dried it in the sun , till the moisture is less than 12%;

3.Put the material into feed let of briquette machine;

4.Produce the briquette stick from biomass material without any additive;

5.Carbonized the briquette stick.

*Crush: We have differetn types crusher deal to different raw materia and capacity , please tell me what is you raw material and you capacity.

*Dryer: We have different types deal to different moisture from 30-70% and different raw materia , please tell me what is you raw material and you capacity.

* Wood briquettes machine : we have differnt size briquettes from 50-80mm, please tell me what is you raw materia and you capacity and you applicationn then I can choose the best size for you .

*Air flow type carbonization stove : This kind of carbonization stove are include three inner stove,when one inner stove are finished, it can be hoisted outside,and when thefirstinner stove are cooling, the other inner stove can be carbonized at the same times, in this way the cooling time can be reduced much,thus, the productive efficiency increase a lot.

|

odel |

Power |

Weight |

Capacity |

Whole machine include |

|

QHL-1(single type) |

0.22kw |

3.3t |

2.5-3t/24h |

1outer stove, 3inner stoves with 3 caps, 1 3ton lifting device, 1 smoking tank |

|

QHL-2( two-connected type) |

1.5kw |

6.8t |

5-6t/24h |

2 outer stove, 6 inner stoves with 6 caps, one 5-ton hoisting equipment with e-motor, 2 smoking tank |

|

QHL-3 (three-connected type) |

1.5kw |

10.5t |

7.5-9t/24h |

3 outer stove, 9 inner stoves with 9caps, one 5-ton hoisting equipment with e-motor,3 smoking tank |

|

QHL-4 (four-connected type) |

1.5kw |

11.6t |

10-12t/24h |

4 outer stove, 12 inner stoves with 12caps, one 5-ton hoisting equipment with e-motor,4 smoking tank |

For one set we packed in standard container.For more sets machines, we pack them in the standard container.