- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1800 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yingwang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1300*820*1400mm

-

Power (kW):

-

4 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

fertilizer mixer blender

-

Quality:

-

Top Level

-

Usage:

-

for oyster mushroom and shiitake mushroom

-

Operation:

-

so easy

-

Production capacity:

-

500-1000bags per hour

-

Material:

-

Carbon Steel

-

Function:

-

bagging mushroom bags

-

Mobile or Viber or WhatsApp or Wechat:

-

0086-18137122335

-

How to purchase:

-

contact with me feely

Quick Details

-

Barrel Volume (L):

-

5500

-

Max. Loading Volume (L):

-

10 L

-

Max. Loading Capacity:

-

500L

-

Weight (KG):

-

1800 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yingwang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1300*820*1400mm

-

Power (kW):

-

4 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

fertilizer mixer blender

-

Quality:

-

Top Level

-

Usage:

-

for oyster mushroom and shiitake mushroom

-

Operation:

-

so easy

-

Production capacity:

-

500-1000bags per hour

-

Material:

-

Carbon Steel

-

Function:

-

bagging mushroom bags

-

Mobile or Viber or WhatsApp or Wechat:

-

0086-18137122335

-

How to purchase:

-

contact with me feely

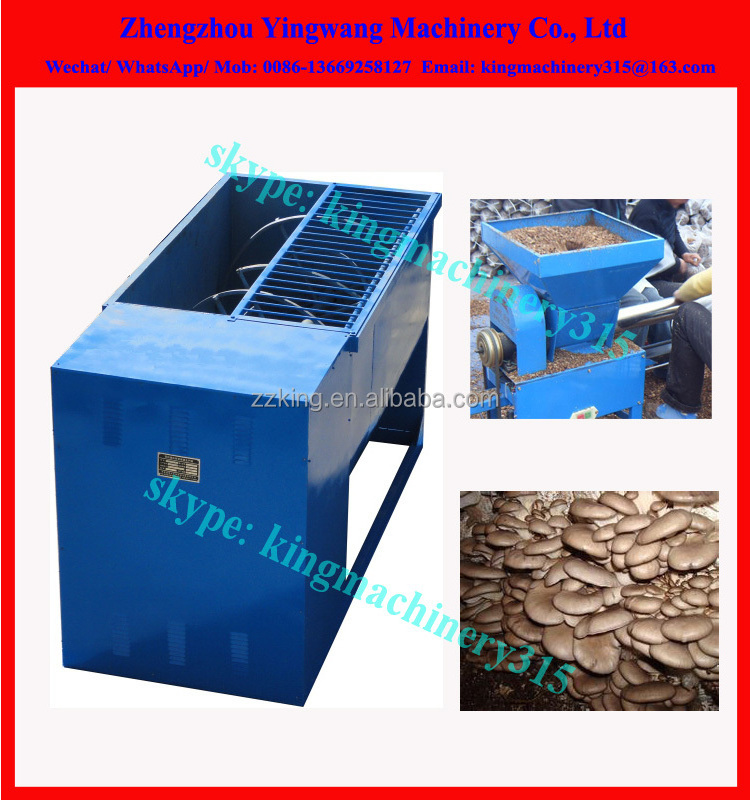

Edible fungus cultivation mixing machine/mushroom compost fertilizer mixer blender/Industrial mushroom substrate mixing machine

A pplication of mushroom bag filling machine

semi-automatic mushroom bagging machine is professional equipment suitable for large-scale mushroom growing plant.

I ntroduction of mushroom bag filling machine:

1,This machine set stamping type bagging machine and screw feeding type bagging machine essence in a body. The design is exquisite. Complete function (bagging, punch, material surface whole even time complete), light weight, no noise.

2,Spiral advance feed, manipulator protection helps bag, no matter how long the bag can according to predetermined standard pack up and down as the actual and put to the standard after automatic stop discharging, manipulator to leveling material surface, and can be in the center to play a diameter 1 -- 3 cm full bag through hole (center inoculation can shorten hair bacteria time by 50%), every time just put the bag cover on easily.

3,The machine is very easy to operate ,even if a hand powerless people to work one day also do not feel tired, the mushroom friend from heavy manual labor in free thoroughly.

4,Sack packer, this machine adopts gear drive, working safely and with a nice looking.

Advantages of mushroom bag filling machine :

1, set stamping bagging and screw feeding

2,easy to operate and large capacity

3, light weight and no noise.

Working step for mushroom growing :

1 Crush raw material to make culture Medium

2 Culture sterilizing

3: All material mixing

4: filling in bag

5: inoculation

6: auto clave Sterilization

7: Finished mushroom

Technical parameters of mushroom bag filling machine :

|

Model |

YW- 80A |

YW- 80B |

YW- 80C |

|

Motor |

3+2.2+4 kw-380v |

3+2.2+4 kw-380v |

3+2.2+4 kw-380v |

|

Filling height |

15-20cm |

30-38cm |

35-40cm |

|

Capacity |

1200bags/h |

800-1000bags/h |

800-1000bags/h |

|

Weight |

1600kg |

1700kg |

1800kg |

|

Size |

4500*2800*1800 |

4500*2800*2500 |

4500*2800*2500 |

|

Conveyor length |

2.5m |

2.5m |

2.5m |

|

Mixer size |

80*200cm |

80*200cm |

80*200cm |

|

Mixing capacity |

200kg/15mins |

200kg/15mins |

200kg/15mins |

Product show

of mushroom bag filling machine

:

.