- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Weight (KG):

-

100 KG

-

Name:

-

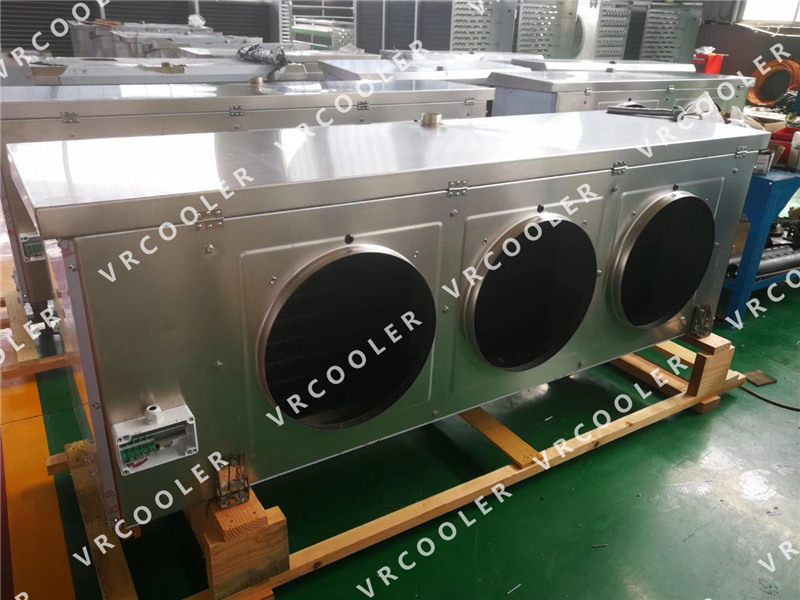

ammonia air cooler unit

-

Fin material:

-

Aluminum, stainless steel, hot dip galvanized steel

-

Fin space:

-

5-20mm

-

Application:

-

Cold storage

-

Cooling capacity:

-

OEM

-

Fan type:

-

Axial Fan

-

Tube material:

-

Stainless steel, aluminum, hot dip galvanized steel

-

Frame material:

-

Stainless steel, aluminum, hot dip galvanized steel

-

Defrost:

-

Hot Gas Defrost, Electrical Defrost, Water Defrost

-

Function:

-

Cooling Ventilation

Quick Details

-

Type:

-

EVAPORATIVE AIR COOLER

-

Mounting:

-

Ceiling Mount

-

Airflow:

-

5000m³/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Weight (KG):

-

100 KG

-

Name:

-

ammonia air cooler unit

-

Fin material:

-

Aluminum, stainless steel, hot dip galvanized steel

-

Fin space:

-

5-20mm

-

Application:

-

Cold storage

-

Cooling capacity:

-

OEM

-

Fan type:

-

Axial Fan

-

Tube material:

-

Stainless steel, aluminum, hot dip galvanized steel

-

Frame material:

-

Stainless steel, aluminum, hot dip galvanized steel

-

Defrost:

-

Hot Gas Defrost, Electrical Defrost, Water Defrost

-

Function:

-

Cooling Ventilation

Product description

1. Rational Design

·

Experienced engineers use Italian advanced design software to design, meeting the demand accurately

·Product suitable to the latest refrigerant such as R410A, CO2, ammonia, glycol and other special refrigerants are available

·Pipeline design adopts the direct oil return and counter-current heat exchanger to avoid the accumulation of refrigeration oil, which make full use of the heat transfer area, improve the heat exchange efficiency and ensure the degree of superheat

2. Reliable raw materials

·

The fans of air cooler are famous brand ZIEHL-ABEGG and EMB, reasonably match with the gap between blades and blast rings, and the design of hyperbolic air duct to achieve the maximum effect

·Copper tubes are multi-tooth and internal thread with high-efficiency. The copper rate is more than 99.9%. All of these increase the surface area and heat transfer efficiency.

·Shell material of air cooler is 3003 aluminum alloy or DC51-D+180g. The paint is outdoor type and treated with high-temperature curing, which makes the shell high in strength and anti-corrosion.

3. Quality control in all

·

Management of factory was approved by ISO9001-2008 and product quality control is through all courses

·Quality control in all: incoming quality control process inspection, finished product inspection.

4. Various choices

·

Provide multiple models and size, choices of fin and coil type to meet the demands of different applications

·A variety of anti-corrosion treatment products, stainless steel products and other customized products are available

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

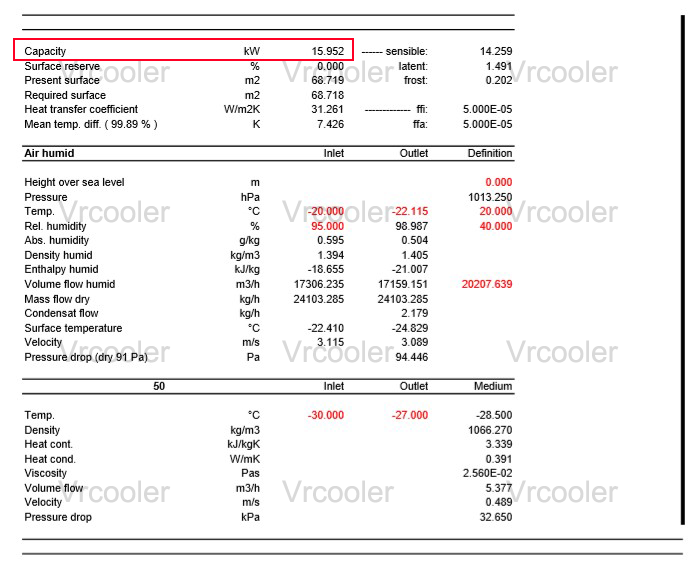

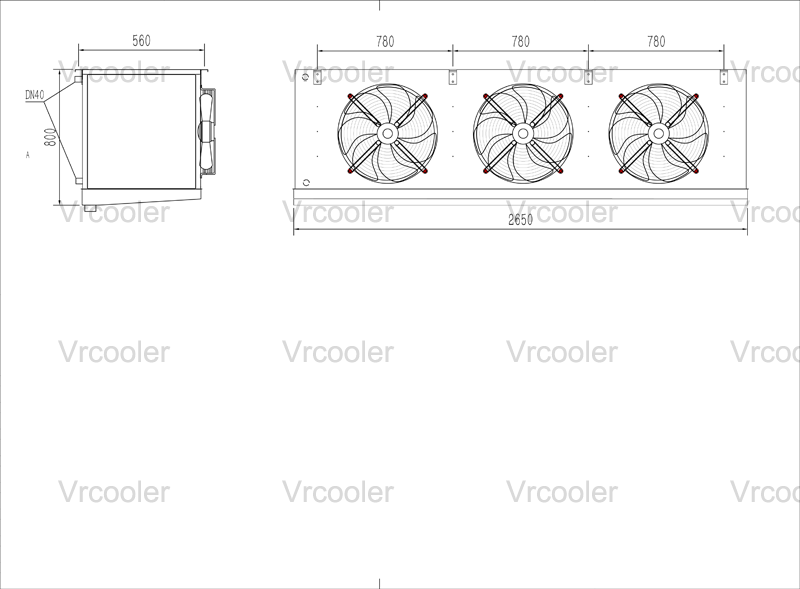

Case study

Projects name

: Ammonia air cooler for

Finland customer

Our questions:

Cooling capacity?

Evaporating temperature?

Room temperature?

Material you need? Stainless steel tube aluminum fin galvanized steel frame or not?

Defrost type? Water defrost, air defrost or electrical defrost?

It is aqua ammonia or ammonia?

It’s pump system or direct expansion system?

Evaporating temperature?

Room temperature?

Material you need? Stainless steel tube aluminum fin galvanized steel frame or not?

Defrost type? Water defrost, air defrost or electrical defrost?

It is aqua ammonia or ammonia?

It’s pump system or direct expansion system?

Customer's information:

Capacity 15kw,

ammonia pumped inlet temperature -30C,

Room temperature -25C

Material need SS tube, aluminum fin, galvanized France ( SS frame on option )

Defrost type need electrical

Fan power 230 1phase or 400v 3phase, 50 hz

Quantity 3-10 units

Our solution:

Engineering Data

We have customized products for many customers, following are some projects we did before.

We can provide designing data and production drawings.

We promise we use the

design software

sold by a well-known

European HAVC software

company.

Through 8 years of cooperation with them, we have designed, processed and exported dry coolers to various countries all around the world.

All of customers feedback is that the actual cooling performance is almost the same as the theoretical design value.

Customer feedback photos

Projects for Peru Food factory

Projects for

Soy sauce factory in Thailand

Projects for

myanmar ammonia cold room

Projects for Canada green house

Projects for Russia cold room

Projects for

Cargo hold on board in

Philippines

Our Company

MORE THAN 15 YEARS OF SUCCESS

Changzhou Vrcoolertech Refrigeration Co.,Ltd specializes in researching, manufacturing and exporting Heat Exchangers, Evaporators, Condensers, air cooler and other heat transfer equipments for the varied industries since 2004.

OUR MISSION

We are committed to quality products and services to meet our customer's expectations and the needs of industrials. We are dedicated to our mission and goal and we believe in long term business relationship with our customers which is based on integrity, responsiveness and quality

A STRATEGIC LOCATION

Address: Qingsitang, Henglin Town, Wujin Dist, Changzhou, Jiangsu, China.

Tel: +86-0519-81695177

E-mail: info@vrcooler.com ; sales@vrcooler.com

Website: www.vrcoolertech.com ; www.vrcooler.com

QUALITY CERTIFICATES

Since 2004 UNI EN ISO 9001:2008 Quality System

Since 2005 UNI EN ISO 14001:2004 Environmental Management System

Packing and delivery

The normal package is wooden box.

If export to european countries,the wooden box will be fumigated.

If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Hot Searches