- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

27.12MHZ

-

Welding Area:

-

200~500

-

Usage:

-

Plastic welding

-

Weight (KG):

-

930 KG

-

Power (kW):

-

8

-

Product name:

-

welding machine price

-

Name:

-

high-frequency plastic welding machine

-

Overcurrent protection:

-

NL5557

-

Certification:

-

CE Certificate

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

QO

-

Voltage:

-

3p*380VAC 50~60hz

-

Frequency:

-

27.12MHZ

-

Welding Area:

-

200~500

-

Usage:

-

Plastic welding

-

Weight (KG):

-

930 KG

-

Power (kW):

-

8

-

Product name:

-

welding machine price

-

Name:

-

high-frequency plastic welding machine

-

Overcurrent protection:

-

NL5557

-

Certification:

-

CE Certificate

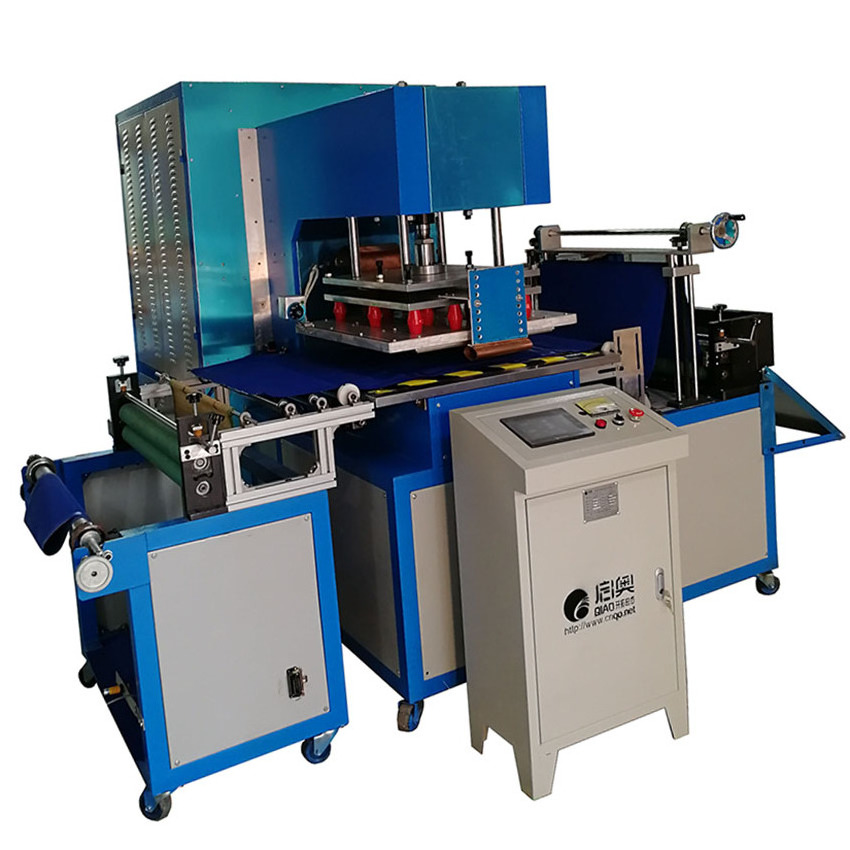

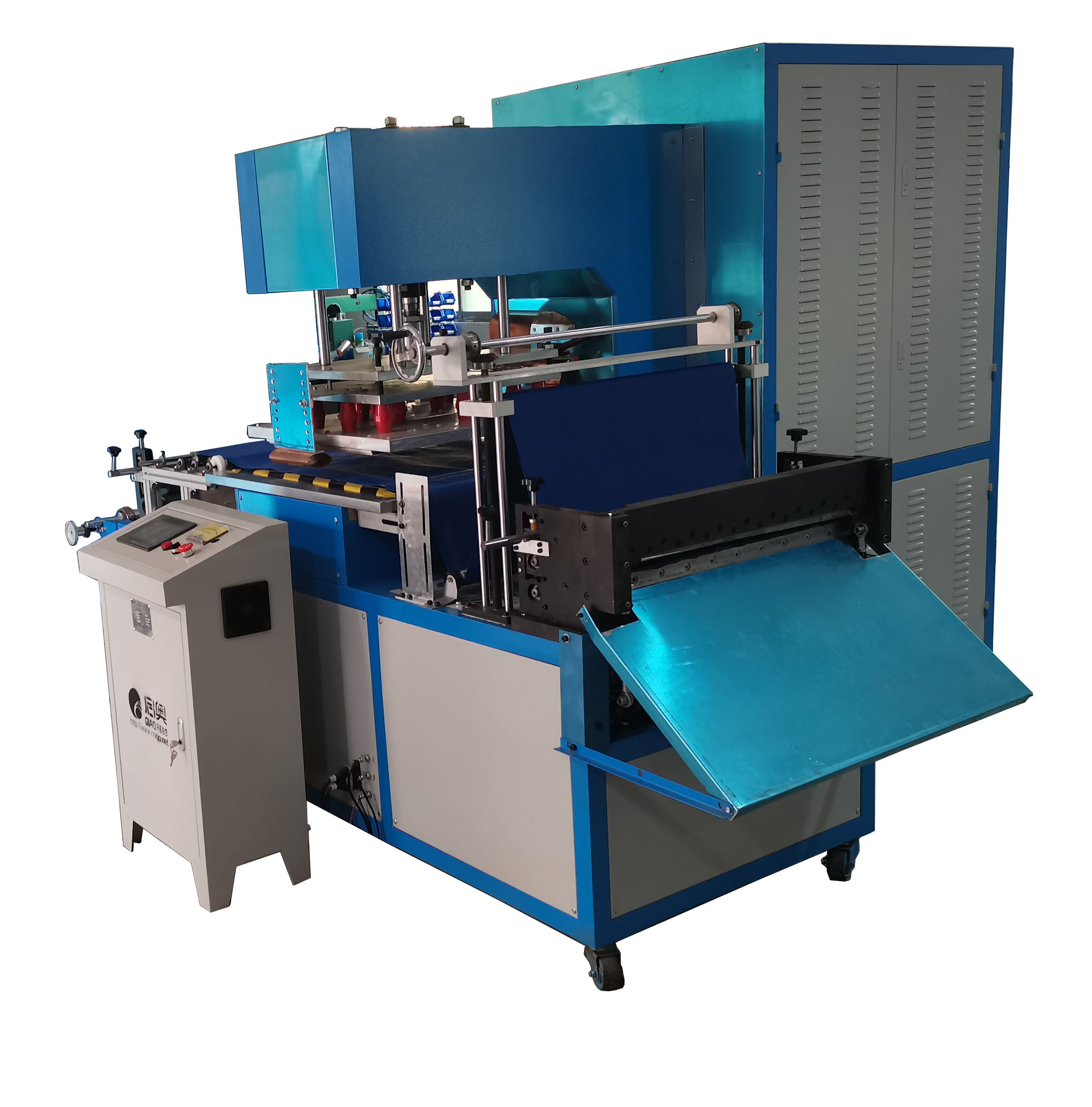

Products Description

Application:

Membrane structure welding machine are Suitable for outdoor film structure, open-air tent, advertising inkjet cloth,

tarpaulin tent , tensioned membrane, Cable membrane , awning, parking shed, landscape architectural membrane structure,

flexible biogas pool, inflatable boats, oil storage tanker, PVC bag, spire membrane structure of PVC/TPU membrane structure

welding or splicing

Product Paramenters

|

Model

|

QO-5KWFB

|

QO-8KWFB

|

QO-10KWFB

|

QO-15KWFB

|

QO-25KW

|

||||

|

Power Range

|

5KW

|

8KW

|

10KW

|

15KW

|

25KW

|

||||

|

Input Power

|

8KVA

|

15KVA

|

18KVA

|

25KVA

|

35KVA

|

||||

|

Power Supply

|

3P *380V/2P*220V/or customization offerded/50Hz-60Hz

|

|

|

|

|

||||

|

Oscillation Tube

|

7T85RB

|

7T69RB

|

E3130

|

8T85RB

|

8T25RA

|

||||

|

Suitable Welding Area

|

100cm

2

|

200cm2

|

250cm2

|

350cm2

|

500cm2

|

||||

|

Size of Work Table (L*W)(mm)

|

350*700

|

450*1050

|

450*1050

|

450*1100

|

450*1200

|

||||

|

Size of active horn

|

150mm

|

|

|

|

|

||||

|

Rectifier

|

Silicon Diode

|

|

|

|

|

||||

|

Working Frequency

|

27.12MHz

|

|

|

|

|

||||

|

Welding Time

|

0.01~9.99s adjustable

|

|

|

|

|

||||

|

Drive Mode

|

Pneumatic Operated (Hydraulic pressure upon request)

|

|

|

|

|

||||

|

Arc suppressor

|

NL-5557 High sensitive anti-spark system

|

|

|

|

|

||||

|

Net weight

|

400kg

|

800kg

|

800kg

|

960kg

|

1200KG

|

||||

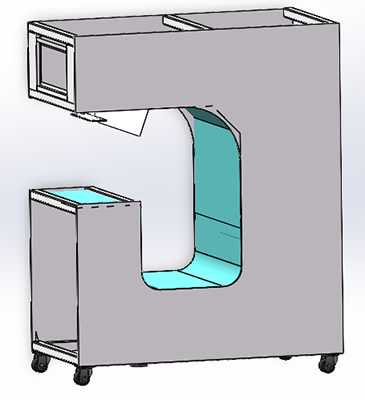

Details Images

Packing & Delivery

Plywood Case

Standard export packaging (plywood case, no fumigation needed)

Delivery

FAQ

FAQ

1. Q: Are you factory?

A: Yes, we are factory, all machine is made by ourselves, and we also offer customization

2. Q: Where is your factory? Can I visit your factory?

A: Longgang District , SHENZHEN city , GuangDong Province. welcome to visit our factory.

3. Q: How to pay our machine?

A:30% TT as deposit,70% balance before shipment by T/T

4. Q: What about your warranty?

A: 1 year, Life-long tech support

5. Q: What about lead time?

A:5-10 working days for standard machines, but 30-90 working days for customized

6.Q: How long we will get the machine?

A: We and our clients usually choose the delivery by sea, so once you place the order, we will arrange the delivery within 10-30days, and about 7-35days (depend on the destination port) you will get the machine.

7.Q:Is it difficult to install the machine?

A: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine, you just need to connect power and compressed air to machine, the begin to operate the machine

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly--you will get install videos, and install instructions from us, it will be an ABC thing to install machines at your side.

8. Q: Could you make die/mould for me, if buy machine from your factory?

A: We design and make die/mould up to product sample or drawings. We charge the mould price at factory cost price.

A: We and our clients usually choose the delivery by sea, so once you place the order, we will arrange the delivery within 10-30days, and about 7-35days (depend on the destination port) you will get the machine.

7.Q:Is it difficult to install the machine?

A: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine, you just need to connect power and compressed air to machine, the begin to operate the machine

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly--you will get install videos, and install instructions from us, it will be an ABC thing to install machines at your side.

8. Q: Could you make die/mould for me, if buy machine from your factory?

A: We design and make die/mould up to product sample or drawings. We charge the mould price at factory cost price.

Related Products

Certifications

Our services

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

.

Hot Searches