- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%, ±1%

-

Packaging Type:

-

Cups

-

Voltage:

-

380

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

1250*1250*1650mm

-

Weight:

-

250 KG

-

Keyword:

-

Cup Filler

-

Productivity:

-

800cups/h

-

Filling Nozzles:

-

1 Head

-

Cup Diameter:

-

30-120mm (Customized)

-

Filling Volume:

-

50-300ml (Customized)

-

Sealing Film:

-

Plastic Roll Film, Plastic PreCut Film, Aluminum Pre-Cut Film

-

Control System:

-

Touch Screen + PLC Control

-

Applicable:

-

Yogurt, Water, Ice Cream, Sauce, Honey, Seasoning, etc.

-

Feature:

-

High Precision Filling Level

Quick Details

-

Machinery Capacity:

-

1000BPH

-

Packaging Material:

-

Plastic, Metal

-

Filling Material:

-

Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±1%, ±1%

-

Packaging Type:

-

Cups

-

Voltage:

-

380

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

1250*1250*1650mm

-

Weight:

-

250 KG

-

Keyword:

-

Cup Filler

-

Productivity:

-

800cups/h

-

Filling Nozzles:

-

1 Head

-

Cup Diameter:

-

30-120mm (Customized)

-

Filling Volume:

-

50-300ml (Customized)

-

Sealing Film:

-

Plastic Roll Film, Plastic PreCut Film, Aluminum Pre-Cut Film

-

Control System:

-

Touch Screen + PLC Control

-

Applicable:

-

Yogurt, Water, Ice Cream, Sauce, Honey, Seasoning, etc.

-

Feature:

-

High Precision Filling Level

PRODUCT DESCRIPTION

High Performance Automatic Rotary Yogurt Cup Filler and Sealer Machine

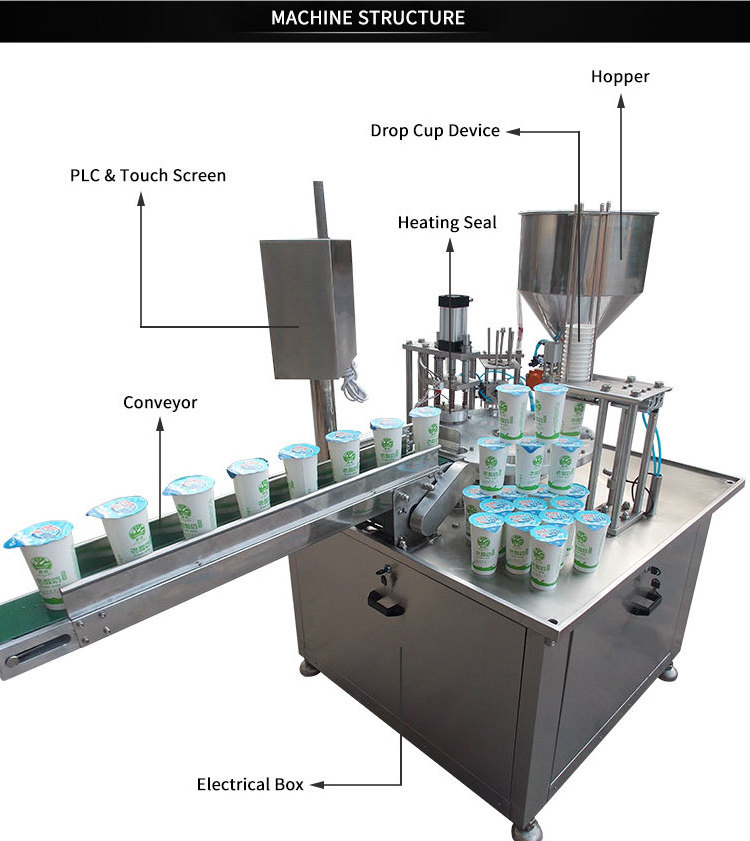

HTC-1 Rotary Cup Filling Sealing Machine adopts pneumatic gap operation mode. The electric appliance adopts a German programmable logic controller, which has the functions of automatic cup drop, filling, vacuum film, single-channel heat sealing, and automatic discharging of the finished product. Adopts an intelligent digital display temperature control system to control the sealing temperature, the temperature error is less than ±1%, the sealing strength is high, and the sealing performance is good.

Suitable For:

Yogurt, Water, Ice Cream, Sauce, Honey, Seasoning, etc.

SPECIFICATIONS

|

Parameters

|

Number Reference

|

|

|

|

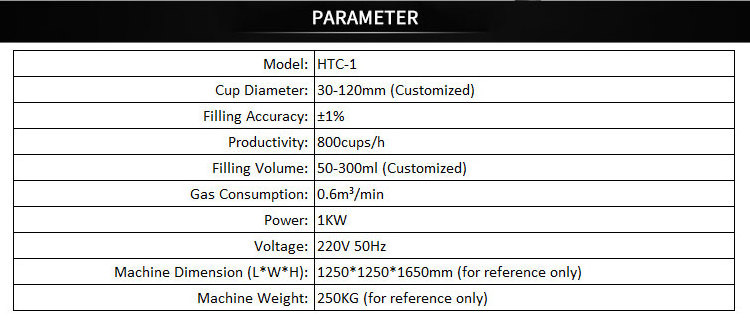

Model

|

HTC-1

|

HT-NC-2, HT-KC-2

|

|

|

Productivity

|

800cups/h

|

1200-1600cups/h

|

|

|

Filling Head

|

1 Head

|

2 Heads

|

|

|

Cup Diameter

|

30-120mm (Customized)

|

|

|

|

Filling Volume

|

50-300ml (Customized)

|

|

|

|

Filling Accuracy

|

±1%

|

|

|

|

Sealing Film

|

Plastic Roll Film, Plastic Pre-Cut Film, Aluminum Pre-Cut Film

|

|

|

|

Control System

|

Touch Screen + PLC Control

|

|

|

|

Gas Consumption

|

0.6m³/min

|

|

|

|

Power

|

1KW

|

|

|

|

Voltage

|

AC380V/220V, 50Hz/60Hz

|

|

|

|

Machine Dimension

|

1250*1250*1650mm (for reference only)

|

|

|

|

Machine Weight

|

About 250KG

|

|

|

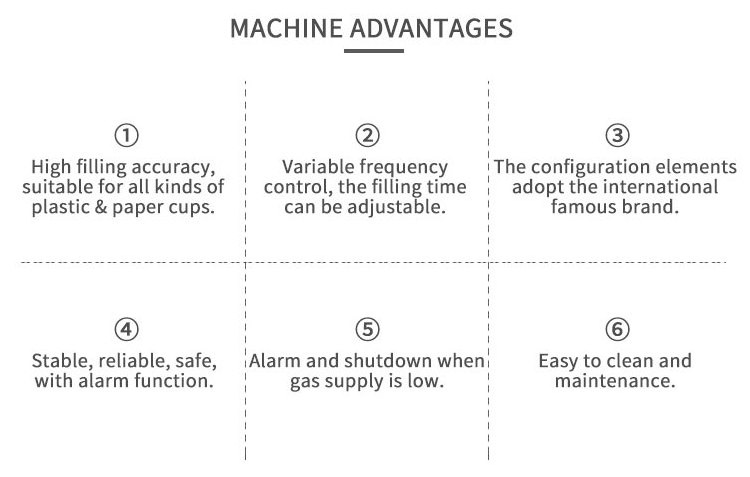

FEATURES AT A GLANCE

1.

The sealing strength is high, and the sealing performance is good.

2.

The body is made of stainless steel, which meets relevant food hygiene standards.

3.

Suitable for all kinds of imported and domestic aluminum-plastic, PP, PZ, CPP, and other composite roll packaging and sealing materials. It is widely used in plastic boxes for beverages, milk, yogurt, dairy products, soy products, fruit frozen brewing and other industries.

4.

Equipped with a solid-state PLC and a touchscreen HMI gives the flexibility to configure the equipment properly for your application.

RECOMMEND PRODUCTS

PACKAGING

COMPANY PROFILE

Hot Searches