- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Head:

-

Single head

-

Type:

-

Hydraulic

-

Control:

-

PLC

-

Station:

-

Two

-

Function:

-

Reducing, expanding, and flange

-

Power:

-

7.5kw

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

tube end forming machine:

-

tube end forming machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CARE

-

Weight (KG):

-

1200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Head:

-

Single head

-

Type:

-

Hydraulic

-

Control:

-

PLC

-

Station:

-

Two

-

Function:

-

Reducing, expanding, and flange

-

Power:

-

7.5kw

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

tube end forming machine:

-

tube end forming machine

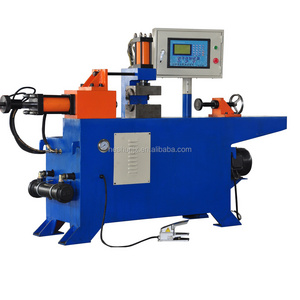

New Automatic Hydraulic Conical Tube End Forming Machine Single Station for Forming One Tube into Another with Reliable Motor

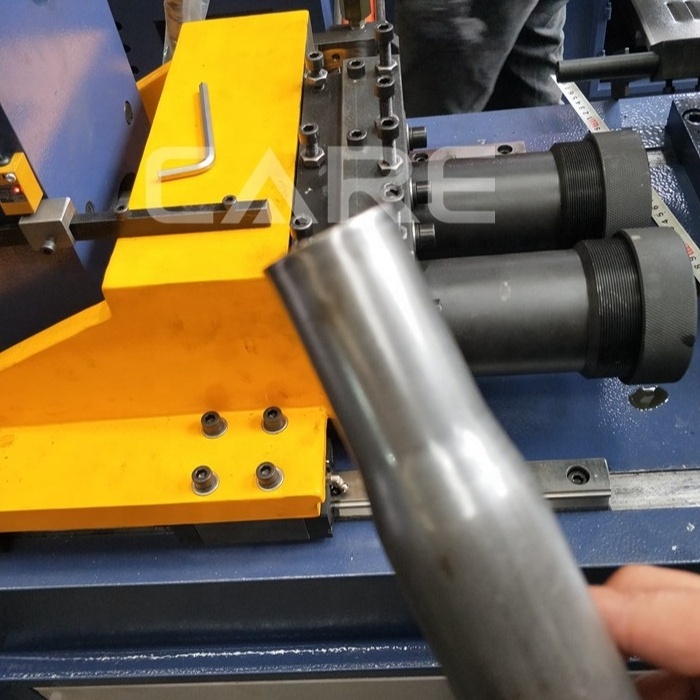

Application: Tube end forming machine is widely used in numerous end forming applications and industries, such as automotive exhausts, furniture, air conditioning, among others. Forming controlled by hydraulic, clamping controlled by hydraulic. PLC controller with English language.

Main specification

1) PLC control Unit: Easy Operation and Maintenance

2) Suitable for the shrinking of various metal pipes with different material and different shape

3) Equipped with emergency stop device. Both manual and automatic operations are available

4) Shrinking stroke 150mm. The max. workpiece length is 450mm, with no minimum workpiece length

5) This machine can make pipe end reducer, expander, flange and flare depend on different forming molds

Technical parameter

|

Type |

SG-40 |

SG-60 |

SG-80 |

SG-100 |

|

Max tube(mm) |

φ40*2.0 |

φ60*2.0 |

φ80*3.0 |

φ100*3.5 |

|

Max processing length(mm) |

110 |

130 |

150 |

180 |

|

Oil pressure(Mpa) |

14 |

14 |

14 |

14 |

|

Working speed |

100mm in3-4/s |

100mm in3-4/s |

100mm in3-4/s |

100mm in3-4/s |

|

Size(cm) |

180*45*120 |

200*50*130 |

290*70*140 |

300*75*150 |

|

Weight(kg) |

600 |

950 |

1600 |

1800 |

|

Remark |

1.The max processing length can according to customers requirement. |

|||

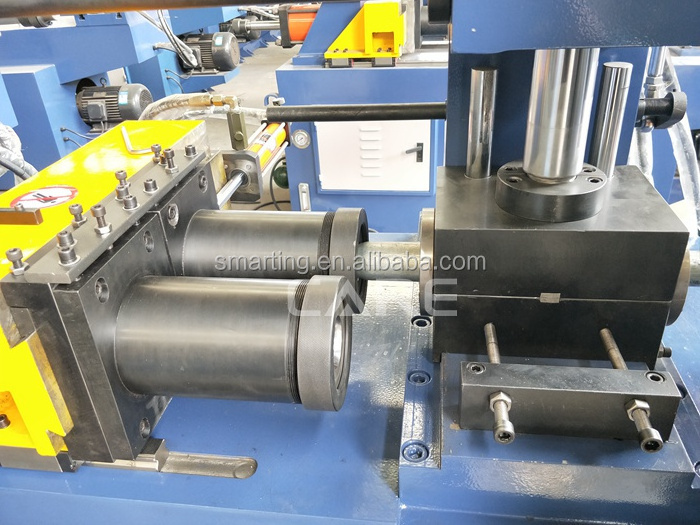

Machine photo