- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

6000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

6200*2240*1850mm

-

Power (kW):

-

9

-

Weight (KG):

-

4000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

working area:

-

2000*6000

-

spindle:

-

9kw air cooling spindle

-

driver:

-

japan yaskawa driver and motor

-

Control system:

-

Syntec

-

Transmission:

-

XY-axis:rack Z axis ballscrew

-

Working table:

-

vacuum table

-

Software:

-

Ucancam / ArtCam/TYPE3

-

ATC tools:

-

linear 12

-

Certification:

-

CE ISO

Quick Details

-

Working Table Size(mm):

-

2000*6000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

6000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

6200*2240*1850mm

-

Power (kW):

-

9

-

Weight (KG):

-

4000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

working area:

-

2000*6000

-

spindle:

-

9kw air cooling spindle

-

driver:

-

japan yaskawa driver and motor

-

Control system:

-

Syntec

-

Transmission:

-

XY-axis:rack Z axis ballscrew

-

Working table:

-

vacuum table

-

Software:

-

Ucancam / ArtCam/TYPE3

-

ATC tools:

-

linear 12

-

Certification:

-

CE ISO

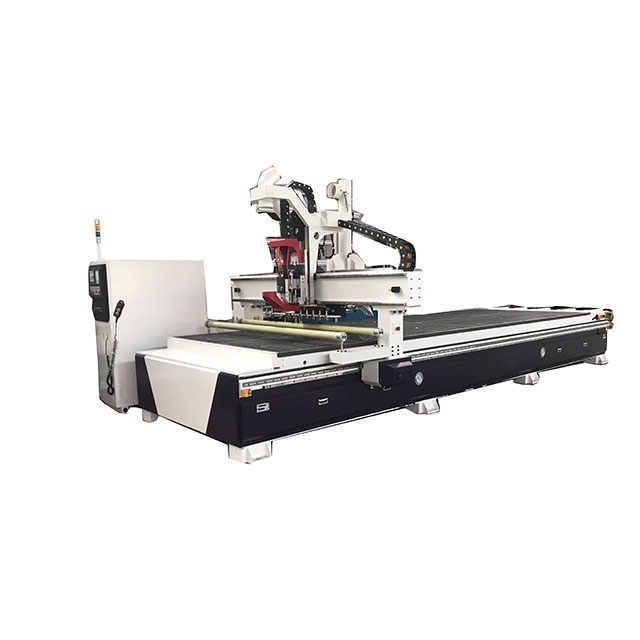

Fast speed 3 axis cnc ATC wood cnc router ST2060 automatic tool changer 12 piece for 3d carving cnc for wood door cabinet

Main specification

1. heavy duty structure table with heat-treatment .which can not be deformation in long time .

2. 9KW Italy spindle peumatic linear 12 piece or round disck atc ISO30 shank

3.Japan yaskawa driver and motor

4. syntec control 6MB for 4 axis

5.Vacuum table with T slot

6. fixed peumatic cylinder for fixed wood at right position

7.nesting table for optional

8. presswheel for optional

9. vacuum cups for optional

10. c axis for optional

|

Working area |

2000*6000*400mm |

|

Table size |

6480*3200mm |

|

Table type |

Vacuum table |

|

X,Y,Z Traveling Positioning Accuracy |

±0.01/400mm |

|

X,Y,ZRepositioning Accuracy |

±0.03mm |

|

spindle |

9 kw italy air cooling spi ndle |

|

Spindle rotating speed |

0-24000rpm/min |

|

cutters |

10 cutters(6mm/12.7mm) |

|

MAX Travelling Speed |

90000mm/min |

|

MAX Working Speed |

30000mm/min |

|

Tool Magazine |

Linear Type ATC, Capacity12 Tool Changing |

|

Guider |

30 Taiwan PMI linear guider |

|

Transmission type |

Gearwheel for X Y axis,ballscrew for Z axis |

|

Control System |

syntec |

|

Motor |

servo motor |

|

Driver |

japan yaskawa850w motor |

|

Inverter |

Delta inverter |

|

Software |

UCANCAM V9 or Type3 |

|

Command |

G code*.u00*.mmg* plt |

|

Surroundings for software |

windows98/2000/xp |

|

Working voltage |

AC380V 50Hz |

|

Packing size |

one 40 container |

|

N.W |

35000kg |

|

G.W |

40000kg |

|

Hs code |

8465990000 |

Main parts

12mm thickness square steel welded by cnc machine center welding then heat treatment removl steel rigidity itself to use many years no deformed .

working sample

our workshop

certificate

service

1. Service before order: our salesman will try to know more about your demands , including the max working size, main processing materials and the thickness , so we will offer you suit machine.

2. Service during production : we will send the production the machine pictures for customer in time , customer can know more the detailed machine parts.

3. Service before shipping : the machine parts will be installed and tested by our professional.

technician, send the test video according to customer’s processing materials for customer confirmations.

4. Service after shipping : we will check when the machine arrive your sea port or the approximate arrival date, so that the customer can know the arrival date and to prepare to pick the machine up

5. Service of training : the English manual and operating video will be sent to customers with the machine together, it will help customer how to operate the machine , it there is any question about the operation , we will have the professional technician to help them how to operate by online ,until the customer can use it freely.

6. Service of warranty : we guarantee the machine for 18month , some machine parts ( quality problems ) can be free charge to replace it within warranty.

RFQ

Feedback for customer