Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands.

- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Hunting Shooting

-

Feature:

-

2 blades or Custom

-

Size:

-

100 125 150 grains or Custom

-

Assemble:

-

Custom

-

MOQ:

-

5000

-

Packing:

-

Custom

-

Manufacture process:

-

Metal Injection Molding

-

Payment Term:

-

Multiple

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Product Name:

-

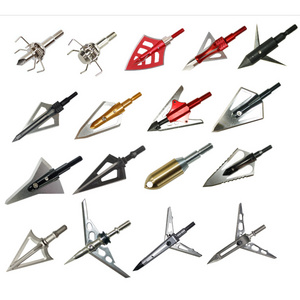

Broadhead

-

Material:

-

Stainless Steel

-

Usage:

-

Hunting Shooting

-

Feature:

-

2 blades or Custom

-

Size:

-

100 125 150 grains or Custom

-

Assemble:

-

Custom

-

MOQ:

-

5000

-

Packing:

-

Custom

-

Manufacture process:

-

Metal Injection Molding

-

Payment Term:

-

Multiple

Related Products

Products Description

|

Material

|

Stainless Steel Broadhead

Support for Custom

|

|

Shape

|

Custom

|

|

Size

|

100 grains

125 grains

150 grains

Support for Custom

|

|

Hardness

|

HRC 42~45 or Custom

|

|

Color

|

Black

Support for Custom

|

|

MOQ

|

6000 pcs for each size

|

|

Lead Time

|

2 weeks for mold development

2 weeks for production

|

|

Process

|

Metal Injection Molding

|

Product details

FAQ

How long can I get my products?

The lead time depends on the products you choose.

1) For the new customized products, we need

2 weeks for mold development

and

1 more week to produce sample

for your approval.

2) For the products which has existing mold, normally

2 weeks for mass production

is enough.

3) Some products need longer lead time due to special process or requirements, we will

update the status in-time

.

What is your advantages?

1)

Perfect Satisfaction Index:

The positive comments of customers are the best explanation.

2)

Customer-oriented service

:

Various options for customer's choices for cost reduction and perfect performance.

3)

Professional Engineer team

:

A professional engineer team provide supports.

4)

Decades of Experience

:

Over a decade experience accumulated basis for customers.

How make sure the customized product meet requirements?

1) We have

official process flow

for new products to guarantee the customer's demands.

2)

Drawings would be sent

for confirmation

before mold development.

3)

Samples would also be provided for approval

before mass production.

4) Mass production would not start until getting the official directions from customer, all the details operated according to approved samples.

Production process

KELU HAS TWO CORE TECHNOLOGIES, MIM AND CNC FOR HIGH-END SPORT COMPONENTS.

Metal injection molding (MIM) is a revolutionary technology which integrating Plastic Injection Molding, Polymer chemistry, Powder metallurgy and Metallic materials science. We can develop mold for special customized size/shape or produce by existing mold directly.

Payment and Shipment

VARIOUS PAYMENT METHODS

MULTIPLE SHIPPING WAYS

Our Customers

Customer Service

Tel: +86-0769-23020611 +86-13527999510

Mails: jane@kelushare.com sales@kelushare.com

Website: https://kelushare.en.alibaba.com www.kelushare.com

Hot Searches