- Product Details

- {{item.text}}

Quick Details

-

Machinery Capacity:

-

depends on machine

-

Machinery Function:

-

cutting food

-

Brand:

-

sheetalsoninc

-

Raw material:

-

titanium alloy

-

Size:

-

customized

-

MOQ:

-

1 Unit

-

Keywords:

-

ultrasonic food cutting machine

-

Usage:

-

ultrasonic

-

Application:

-

Rubber, vulcanized latex,

-

Suitable for:

-

Cake Cutter

-

Certification:

-

Certified

-

After Warranty Service:

-

Video technical support

Quick Details

-

Weight (KG):

-

6

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sheetalsonic

-

Machinery Capacity:

-

depends on machine

-

Machinery Function:

-

cutting food

-

Brand:

-

sheetalsoninc

-

Raw material:

-

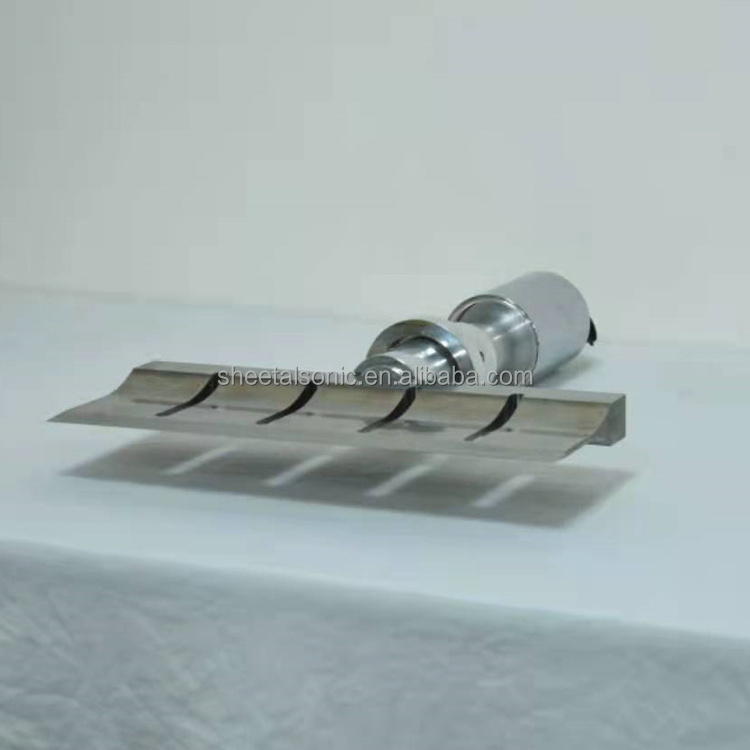

titanium alloy

-

Size:

-

customized

-

MOQ:

-

1 Unit

-

Keywords:

-

ultrasonic food cutting machine

-

Usage:

-

ultrasonic

-

Application:

-

Rubber, vulcanized latex,

-

Suitable for:

-

Cake Cutter

-

Certification:

-

Certified

-

After Warranty Service:

-

Video technical support

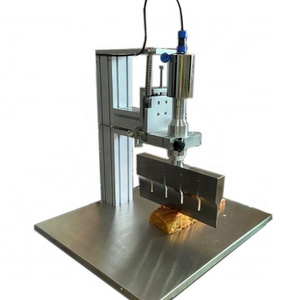

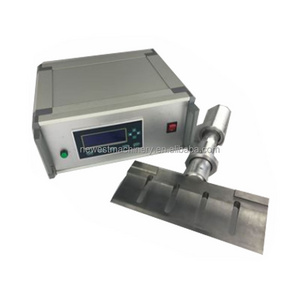

Ultrasonic Food Cutter Titanium Ultrasonic Sonotrode For The Food Industry Ultrasonic Cutter

Traditional cutting

common problem:

1. Need a sharp edge, increase the requirements for the blade.

2. Cloth cutting cannot seal the edges, and the cutting edges are easy to cause chipping and breakage.

3. Sticky objects are difficult to cut, and it is easy to stick to the knife, which affects the cutting effect and efficiency.

4. When cutting, it is necessary to apply pressure to the object, which is easy to deform soft or fragile food.

5. Some items will produce a lot of broken particles and debris when cutting, increasing waste.

2. Cloth cutting cannot seal the edges, and the cutting edges are easy to cause chipping and breakage.

3. Sticky objects are difficult to cut, and it is easy to stick to the knife, which affects the cutting effect and efficiency.

4. When cutting, it is necessary to apply pressure to the object, which is easy to deform soft or fragile food.

5. Some items will produce a lot of broken particles and debris when cutting, increasing waste.

Ultrasonic cutting

High stability

When the ultrasonic generator is working, electromagnetic vibration is generated, which is converted into mechanical vibration and transmitted to the cutting knife and the cut material, and the cutting is performed mechanically, so there is no need for sharp cutting edges, the blade is less worn, and the cutter head can be replaced by itself.

No pollution

When the ultrasonic knife is cutting, the temperature of the knife head is lower than 50 ℃, so smoke and odor will not be generated, which eliminates the danger of injury and fire during cutting.

Neatly cut

Due to the ultrasonic cutting by high-frequency vibration, the material will not adhere to the surface of the blade, and only a small amount of pressure is required when cutting. It will not deform and wear for fragile and soft materials. The fabric will be automatically sealed at the same time and will not cause collapse. side.

easy to use

The cutting knife is connected to the ultrasonic generator, and the generator is connected to the 220V mains power, and the cutting can be carried out by turning on the switch. It supports hand-held and machine-mounted cutting.

Wide range of applications

Rubber, vulcanized latex, non-vulcanized latex, food and various textile materials, plastic sheets can all be ultrasonically cut.

Hot Searches