- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mingyang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2300*1000*1780mm

-

Motor Power (Kw):

-

45

-

Power (kW):

-

45

-

Weight (KG):

-

4500 KG

-

Product name:

-

ce wood pellet fuel making machine

-

Capacity:

-

800-1200kg/h

-

Usage:

-

home use, industries etc

-

Type:

-

biomass fuel series

-

Raw material:

-

wood sawdust, wood powder, etc

-

Die:

-

4mm, 6mm, 8mm, 12mm etc

-

Final size:

-

4-12mm

-

OEM:

-

acceptable

-

Supply:

-

factory supply directly

-

Operation:

-

easy and convenient

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

400 - 1200 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2300*1000*1780mm

-

Motor Power (Kw):

-

45

-

Power (kW):

-

45

-

Weight (KG):

-

4500 KG

-

Product name:

-

ce wood pellet fuel making machine

-

Capacity:

-

800-1200kg/h

-

Usage:

-

home use, industries etc

-

Type:

-

biomass fuel series

-

Raw material:

-

wood sawdust, wood powder, etc

-

Die:

-

4mm, 6mm, 8mm, 12mm etc

-

Final size:

-

4-12mm

-

OEM:

-

acceptable

-

Supply:

-

factory supply directly

-

Operation:

-

easy and convenient

1-10t/h biomass straw rice husk firewood waste briquette vertical ring die biomass wood pellet making machine

Introduction of the ce wood pellet fuel making machine:

The ce wood pellet fuel making machine is applied to the materials with low adhensiveness and low shaping rate such as rice husk, sunflower seeds husk, peanut shell husk, and other nut shell and fruit shells, this pellet mill is widely used in the biomass-energy fules plant, power plant, wood processing plant, it is the ideal pressing shaping machine with low investments and high profit.

Features of the ce wood pellet fuel making machine:

1. Vertical die, feeding vertically; No arching of raw materials, easy for heating dissipation;

2. Die fixed, rollers rotating, better for even material distribution;

3. Independent lubrication; High pressure filtration, clean and unblocked;

4. Independent and frequency changeable cuting device ensuring high pelletizing rate;

5. The key parts are made of superior alloy steel with heat treatment by German vacuum furnace, so its service life is prolonged by 5-7 times;

6. The machine with the automatic lubricating system that the grease is injected and filtrated automatically, which can ensure the long time working without stop;

7. The dust and cooling system that can reduce the dust during it wotking and improve the woking environment.

Main data of the ce wood pellet fuel making machine:

|

Model |

Capacity |

Power |

Size of Finished pellets |

Weight |

Size |

|

350 |

0.4-0.8 t/h |

35kw |

4-12 mm |

2.8ton |

2000*1000*1380 mm |

|

450 |

0.8-1.0 t/h |

55kw |

4-12 mm |

4.2ton |

2200*1000*1580 mm |

|

550 |

0.8-1.2 t/h |

75kw |

4-12 mm |

4.8ton |

2300*1000*1780 mm |

|

560 |

1.0-1.5 t/h |

90 kw |

4-12 mm |

5.8ton |

2600*1300*2300 mm |

|

650 |

1.5-2.5 t/h |

160 kw |

4-12 mm |

6.5ton |

2900*1300*2400 mm |

|

880 |

3.0-4.0 t/h |

315 kw |

4-12 mm |

12.6ton |

3750*1650*3250 mm |

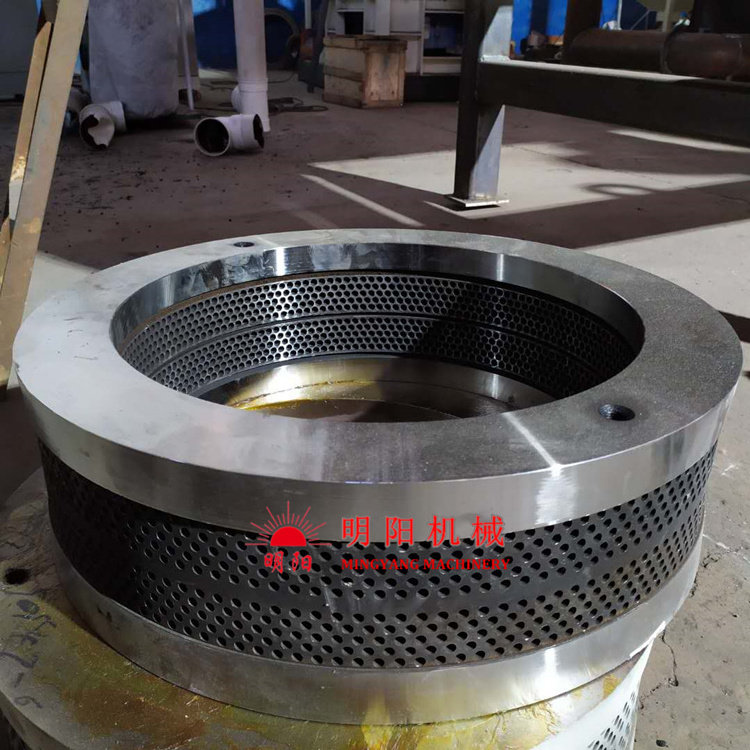

Spare parts of the ce wood pellet fuel making machine:

1. Vertical die, feeding vertically; No arching of raw amterials, easy for heating dissipation;

2. Die fixed, rollers rotating, materials centrifugal, evenly distributed around;

3. Double-layer dies, up and down dual-use, high capacity, saving energy.

Final products of the ce wood pellet fuel making machine: