- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HuaXin

-

Dimension(L*W*H):

-

2479x 2970x 2050 mm

-

Weight:

-

13100 KG

-

Product name:

-

20 ton mill ring granulator coal hammer crusher for hard coal gangue

-

Model type:

-

PCXK

-

Hammer Line Speed:

-

62m/S

-

Rotate speed:

-

590-1480r/Min

-

Crushing type:

-

Grinding and Impact

-

Compressive Strength:

-

100-250 mpa

-

Input Max Feeding Size:

-

200mm

-

Protection way:

-

Reversible Crushing

-

application:

-

Coal Fired Power Plant

-

Keywords:

-

hammer crusher

Quick Details

-

Application:

-

coal crusher

-

Capacity(t/h):

-

Max 600 t/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HuaXin

-

Dimension(L*W*H):

-

2479x 2970x 2050 mm

-

Weight:

-

13100 KG

-

Product name:

-

20 ton mill ring granulator coal hammer crusher for hard coal gangue

-

Model type:

-

PCXK

-

Hammer Line Speed:

-

62m/S

-

Rotate speed:

-

590-1480r/Min

-

Crushing type:

-

Grinding and Impact

-

Compressive Strength:

-

100-250 mpa

-

Input Max Feeding Size:

-

200mm

-

Protection way:

-

Reversible Crushing

-

application:

-

Coal Fired Power Plant

-

Keywords:

-

hammer crusher

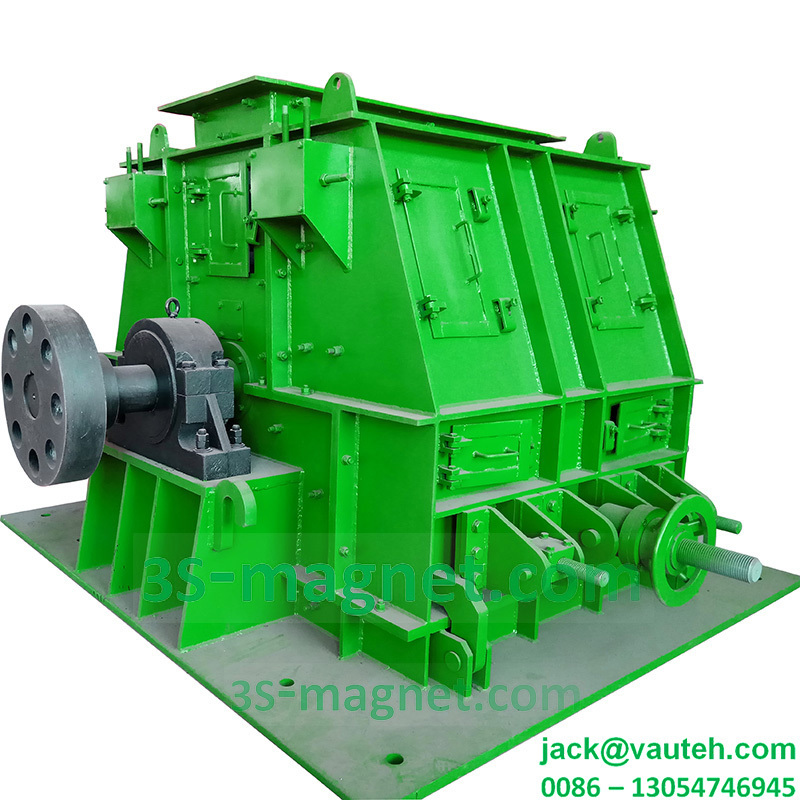

20 ton mill ring granulator coal hammer crusher for hard coal gangue

Introduction of PCXK granule pulverizer grinding ring hammer crusher

HuaXin Ring Hammer Coal Crusher is a punching rotor type crushing machine with ring-hammer on the rotor. The material is firstly crushed by the punching force of the high speed ring-hammer rotating, then the crushed material is thrown forward to crushing plate for the second crushing, required sizes material will be discharged through the sieve plate, but bigger sizes material will be shot back to the ring-hammer again for the third crush. Such process repeats until the materials are crushed to the required size.

Applications of PCXK granule pulverizer grinding ring hammer crusher

- Coal

- Ores

- Limestone

- Clay

- Lime

- Natural and FGD gypsum

- Petcoke

- Aggregates

Features and benefits PCXK granule pulverizer grinding ring hammer crusher

- Large opening for flexibility

- Fully lined crushing chamber for longevity

- Liners are bolted for easy change out

- Grate bars and screens for accurate product sizing that are easily replaceable

- Hammers or rings allowing flexibility

- Forged alloy steel and extreme duty shaft allowing reduced vibration and longer bearing life

- Positive lock housing for extra security from blow outs and dusting

- Adjustable grinding plate for process control

- Multiple rotor configurations to suit any material

- Large discharge opening

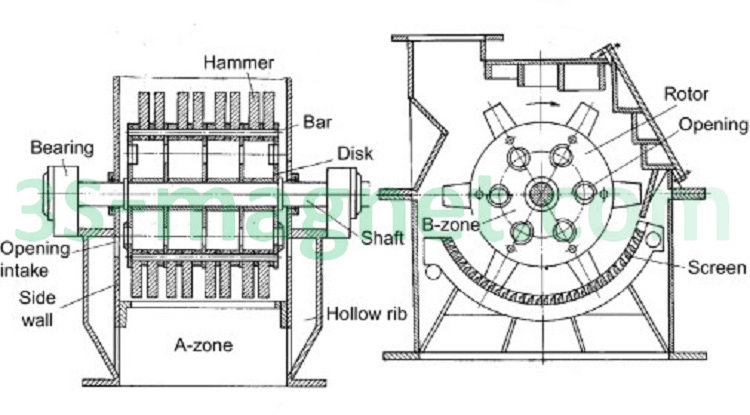

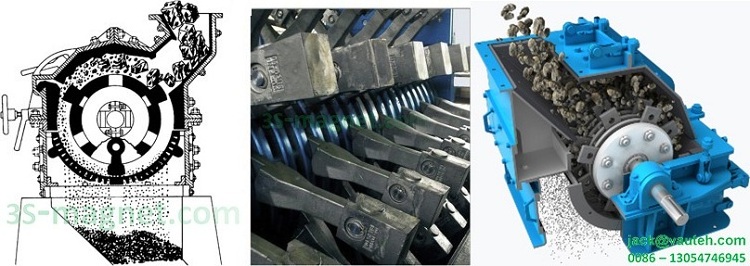

Principle of PCXK granule pulverizer grinding ring hammer crusher

The main shaft drives the rotator and hammers to impact coming material, the material bounces to impact plate for further crushing. The upper half section is impacting area, that is linearity sector, and the lower half is for particle size guarantee area, namely arc sector. The particle size is controlled by adjusting the clearance between hammer and liner plate. Fine particle that up to 3mm accounts for 90%. There is no dead zone for crushing in the arc sector, and the finished particle size ranges from 3mm to 10mm by adjustment.

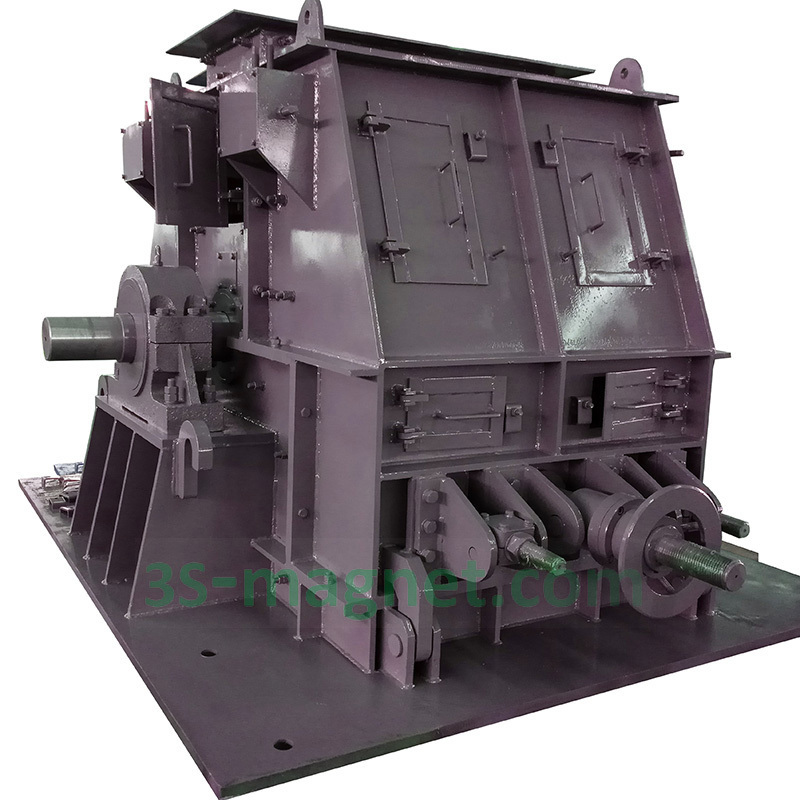

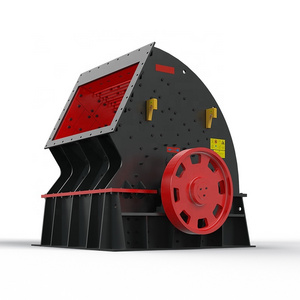

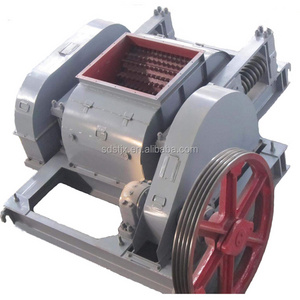

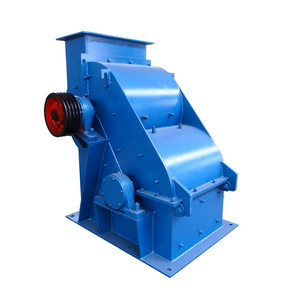

Photos View of of PCXK granule pulverizer grinding ring hammer crusher

Hammer crusher

pulverizer machine

coal power plant

grinding machine

hammer mill crusher machine

Production view

pulverizer grinder machine

grinding hammer crusher

Components of PCXK granule pulverizer grinding ring hammer crusher

1. Shell

The shell is composed of the lower body, the upper rear cover, the left and the right side walls. Each part is connected by bolts. A feeding port is set on the upper part. The inner part of the shell is made of manganese steel, which can be replaced after being worn. The lower body is welded by steel plates in order to place the bearing to support the rotor on both sides of the lower body. A shaft seal device is arranged between the casing and the shaft to prevent ash leakage.

2. Rotor

The rotor design of hammer crusher

The rotor is composed of main shaft, hammer holder, and pin shaft. The hammer is suspended on the hammer holder in eight rows by the pin shaft. In order to prevent the axial movement of the hammer frame and the hammer head, both ends of the hammer frame are fixed with a compression disc and a lock nut. In addition, in order to make the rotor store a certain amount of kinetic energy in motion, flywheel or large pulley should be installed at one end of the main shaft.

3. Main Shaft

The main shaft is the main part supporting the rotor, which needs to bear the mass and impact force from the rotor and hammer head in the process of operation, so its material must have high strength and toughness.

4. Hammer Holder

The hammer holder is used to hang the hammer heads. Although it does not directly participate in the process of crushing materials, it is still subject to the impact and friction of ore and wear, so it should be made of materials with good wear resistance.

5. Hammer

The hammer heads are the core part of a hammer crusher. The weight, shape, and material of hammer heads affect the production capability of the crusher significantly.

The heavier the hammer, the more kinetic energy it possesses, and the higher the crushing efficiency. But heavy hammer also causes more damage to other parts and accelerate their wear process. The hammer weight should be able to balance the production efficiency and the wear rate.

6. Grate

The arrangement of grate bars of the hammer crusher is a circular arc that is perpendicular to the moving direction of hammerhead and has certain clearance with the rotary radius of rotor. The material smaller than the gap between grate bars can pass through the gap, and the material larger than the gap will be continuously impacted, ground and broken by the hammers until it can pass through the gap. Due to the impact of hard materials and metal blocks, the grate is easy to bend and break, so it needs to be inspected and replaced frequently.

7. Lining Plate

The lining plate is installed inside the shell to protect it from the ore. The lining plate is cast by high manganese steel, the same material used for grate bar and hammer. The lining plate can be replaced when it is seriously worn to ensure product quality.

Installation and working site of PCXK granule pulverizer grinding ring hammer crusher

pulverizer machine price

coal mill crusher

Technical Data of of PCXK granule pulverizer grinding ring hammer crusher

|

Model |

Feeding size (mm) |

Out put size (mm) |

Capacity (/h) |

Power (KW) |

Weight (Kg) |

|

PCXK0303 |

50 |

<8 |

2-15 |

5.5-11 |

730 |

|

PCXK0404 |

50 |

<8 |

5-18 |

11-22 |

1120 |

|

PCXK0604 |

60 |

<8 |

8-15 |

30-45 |

2660 |

|

PCXK0606 |

60 |

<8 |

15-25 |

37-55 |

3000 |

|

PCXK0806 |

80 |

<8 |

25-35 |

45-75 |

4500 |

|

PCXK0808 |

80 |

<8 |

30-50 |

55-90 |

5000 |

|

PCXK0908 |

100 |

<8 |

35-70 |

75-110 |

6420 |

|

PCXK1010 |

100 |

<8 |

40-85 |

110-132 |

8200 |

|

PCXK1012 |

100 |

<8 |

50-100 |

132-160 |

9800 |

|

PCXK1016 |

100 |

<8 |

60-130 |

185-220 |

12800 |

|

PCXK1212 |

100 |

<8 |

70-140 |

185-220 |

13100 |

|

PCXK1214 |

100 |

<8 |

90-190 |

220-280 |

15600 |

|

PCXK1216 |

100 |

<8 |

120-220 |

220-315 |

17600 |

|

PCXK1414 |

150 |

<8 |

140-240 |

250-355 |

18500 |

|

PCXK1416 |

150 |

<8 |

160-280 |

315-400 |

20800 |

|

PCXK1616 |

150 |

<8 |

200-320 |

355-500 |

27300 |

|

PCXK1618 |

150 |

<8 |

250-370 |

400-630 |

32000 |

|

PCXK1818 |

150 |

<8 |

270-400 |

450-710 |

36900 |

|

PCXK1821 |

150 |

<8 |

350-470 |

560-800 |

39300 |

|

PCXK1827 |

150 |

<8 |

450-600 |

630-1000 |

42800 |